Any production is a complex system that requires many different tasks to function.

Most of the tasks are self-explanatory and can be done in spreadsheets, messenger chats or 1C Accounting. For example:

- Materials Procurement.

- Equipment Maintenance.

- Quality Control.

- Production Planning.

There are also many MES systems on the market that help manage production and solve more complex tasks that tables can no longer handle. For example:

- Real-time dispatching.

- Work with staff – timekeeping, etc.

Why did we create yet another MES system?

When dealing with existing systems in our manufacturing facility (and we have been in business since 1998 and manufacture complex equipment), we keep running into the high cost and complexity of implementing control systems. The main difficulties are:

- Very complex interface, workers at all levels often can’t use it.

- Not being able to utilize the system by every employee.

- Lack of quick operational management – chats, quick photo sends.

- Not linked to the task system – tasks should appear on the task board for each worker.

- Failure to notify employees – e.g. of a new task, deadline, etc.

- Price – very high prices for solutions, which then still need to be “finalized” and invested heavily in customization.

AATex MES for manufacturing companies

So, we realize from our own experience that most MES systems are overcomplicated and very expensive. At the same time, it requires a huge amount of resources (due to the complexity) to customize the work and train employees.

This results in not all data being entered in the field and not all tasks being completed. This cannot be solved with video cameras.

At the same time, most businesses have their accounting and work systems set up and there is no need to duplicate these systems.

The AATex MES system solves the issue of data transfer and display of tasks and data for all plant employees.

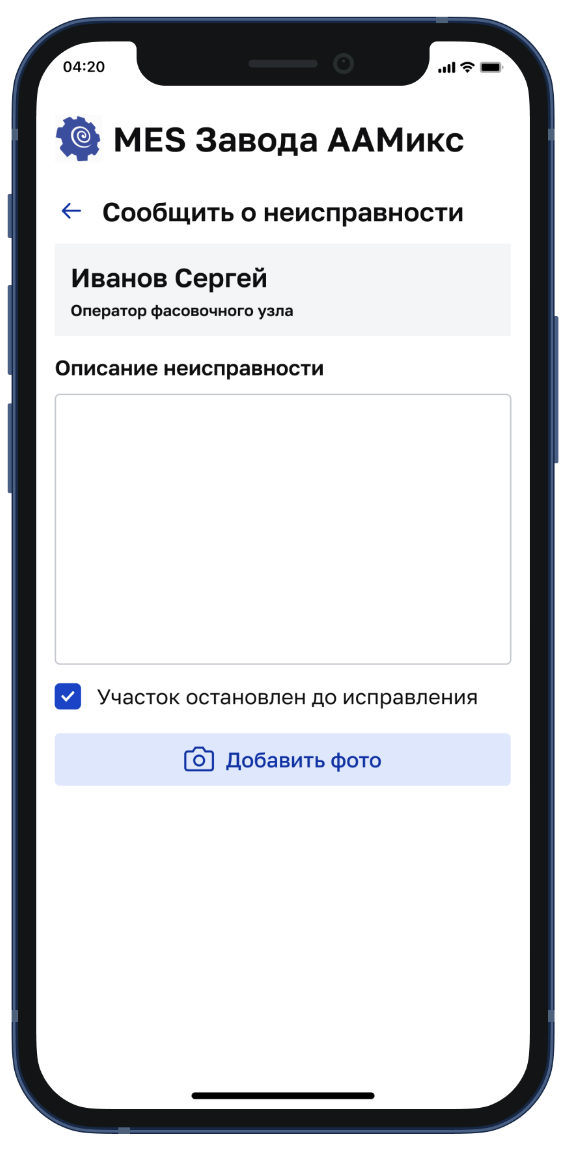

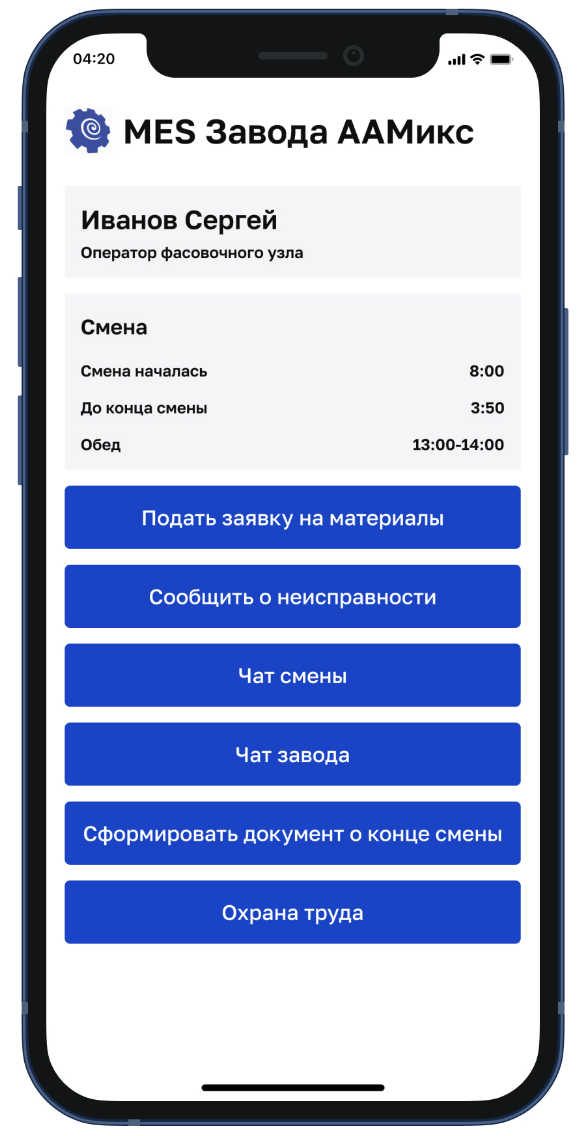

Each employee of the plant installs the MES AATech application on his/her phone – under Aurora, Android, iOS operating systems. The application also works on Windows and Linux computers.

This ensures that each employee has his or her own workplace in which to work:

- Marks arrival / departure to work, lunch. Can be combined with ACS, biometric system.

- Receives assignments that are displayed on a task board (Kanban).

- Inputs data (including photos and videos).

- Participates in the operational management of the plant through chats, photos, video recording.

Typical jobs in the appendix:

- Component receiving and stocking area.

- Packing area.

- Shipping area.

- Technologist, recipes, sampling, quality control – generation of certificates.

- Supplies.

- Chief Engineer – equipment maintenance, motor hours.

- Administration.

- Timekeeping.

- Any other jobs with flexible customization.

AATech’s MES is a familiar way for every worker to receive tasks and input information.

The cost of the system and its maintenance is many times less than typical MES systems, as there is no need for redundant processing of information that is already available at the enterprise.

Production scripts

The word script means a script or a set of actions. In MES AATex you can flexibly customize different scripts for action chains. Here is an example of a central script for most production facilities (of course it can be modified – simplified/complicated).

Script of order receiving, order handling, production and shipment.

- An email or phone or messenger receives the customer’s request.

- A task is created for a manager, a push notification is sent to his phone + email.

- The task appears on the kanban board – response time is 1 day.

- When the manager replies to the client, the task status changes and it is moved to waiting for a reply from the client.

- If the client has not responded in 3 days, a callback reminder is sent and a new task status is set.

- If a client refuses, the reason is specified and once a month a report on refusals with reasons is sent to those users who are added to the mailing list. You can understand why clients refuse, dynamics of refusals, etc.

- If a contract is signed, a task is created in the design department to create a project (tasks are created on the board, push notifications are sent to the designers attached to the project).

- Once the project is approved by the client, a design is created:

- Production order (board tasks are created, push notifications are sent).

- Production tasks move from making parts on machines, to assembly, to painting.

- Purchase order to the logistician (tasks are created on the board, push notifications are sent).

- Once the equipment is manufactured, a task is created for inspection by the GTC.

- Next is shipment – the tasks of ordering a car, etc.

- After the order is finalized, tasks for installation (if needed) are created.

- Tasks are created to collect feedback from the customer.

- Pending tasks are created for six months, a year, etc. in advance with automatic sending of letters to the customer with the offer of spare parts, maintenance, line extension, etc.

The script automates many tasks – transfer of orders to the shop floor, automatic letters to customers, creation of events in the calendar.

We estimate that the implementation of our system will increase turnover and significantly improve staff engagement and productivity.

All work is done by ALL employees of the company on the phone in a familiar and clear interface that you don’t have to learn.

Technology

Client part.

- Native apps for Aurora, Android, iOS, Windows, Linux.

- Web Interface.

Server part.

- The database is Postgre SQL.

- Scripts – data transfer, data processing – Node.js.

- Machine Learning, AI – Python.

How to order an MES system

Since we provide a complete turnkey solution, the customer will not need to customize the system. After implementation, all employees will immediately be able to install applications on their phones and work in a clear, simple and efficient environment.

When ordering, we analyze the customer’s needs and processes, draw up a set of implemented functions, launch the system, and train employees.

The system can work in our cloud (servers in Russia) or on the customer’s servers.

For ordering and cost calculation write info@aatex.ru, Telegram https://t.me/aatexru or call tel.: +7 (812) 408-41-82.