Equipment for packing cement, sand, expanded clay, crushed stone into bags

How to choose the right filling for your request? It depends on what you will be filling and the performance:

packing of simple material into valve bags – cement, ash, any dry mix, capacity up to 10 tons per hour, small production – FAS-KM2

cement, ash, any dry mix, capacity up to 15 tons per hour, automated production – FAS-KM4

dry mixes with coarse aggregates (expanded clay, perlite, vermiculite, etc.), capacity up to 8 tons per hour, automation – FAS-KM3 pneumatic (if you need more, then put 2 filling machines, they can be easily serviced by one operator).

crushed stone, gravel, marble chips and similar, packing into polypropylene bags, up to 5 tons per hour – FAS-1

View prices for prepackaged items.

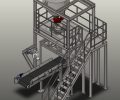

Also we will always help to choose the right scheme of material supply and organize the complete production – to put hoppers, conveyors, automation.

view detailed description of the filling units

see comparison of filling designs

| Equipment for packing crushed stone, gravel, expanded clay in FAS-OM1 bags | Installation of crushed stone and sand in open bags – parallel weighting, automatic stock and / or firmware. |

|

Equipment for packing fertilizers, feed, chemicals in open bags FASO2 | Installation with parallel weight dose and automatic sealing \ suturing of bags. |

|

FAS -km4 – installation of packing in valve bags | The most productive packaging is a sales leader. Fasset in valve bags up to 15 tons per hour! High accuracy, speed, reliability, tested in many factories. Complete automation. |

|

FAS CM3 euro, analogue of Haver & Boecker – installation for packing dry mixtures | Packing in valve bags of mixtures with large fillers – expanded clay, perlite, vermiculite, etc. Full machine, up to 8 tons per hour. |

|

FAS COM2 Rotor-installation for packing dry building mixtures | The productive, reliable and fully automatic installation of packing cement and dry mixes in valve bags, up to 10 tons per hour in bags of 10 to 50 kg. |

| Fertilizer packing line | Typical lines for packing fertilizers in valve bags. |

|

Modernization and restoration of packs Haver & Boeker and other foreign manufacturers | Modernization of control panels, pneumatics, weight systems, mechanics. |

| Paste cement in bags | Description and characteristics of equipment for packing cement in valve bags |