We have been engaged in the production of silos since 1998.

Highly qualified specialists of the company have extensive experience in this area. For the development and production of equipment, innovative technologies and high -quality materials are used, which allows you to successfully compete in the market with foreign firms. The company offers a wide range of products: silos for cement and other bulk materials, screw conveyors, filters, sensors, as well as other similar equipment and components.

At the moment, in the warehouse there is a silos of 20, 40, 60 and 120 cubic meters. That is, the shipment occurs immediately!

Download price listWith pricing for silos and components.

To order silos, write to info@isilos.ru or call +7 (812) 408-41-82

Our production

For 17 years, we have been engaged in the development and production of silos and cement warehouses.

The equipment is designed using special computer programs in which 3D models are created, parts are cut out on the industrial installation of German-made laser cutting.

Welding elements is carried out outside and inside. The use of modern technologies and development provides accurate compliance with the equipment to drawings. The cement silage of our production fully complies with existing standards, is reliable, strength, durability and high quality.

Our works

Silos are installed on many construction enterprises of Russia, including large factories

Ax concrete built using German technology Hess AAC.

Photos of the installation of silos on a gas concrete production plant in St. Petersburg. The volume of silos is 120 cubic meters.

Customer – CJSC “Stroykomplekt”. Silos was produced by the Stroy-Baton plant.

Product characteristics

All the details of the silos and the supporting frame are made of high -quality steel. Double welding of the seams is used – outside and from the inside. Thanks to this, the reliability and durability of the equipment when working in any climatic conditions is ensured. For the manufacture of parts, steel is used 6-10mm thick in the lower parts of the silage and from 4mm in the upper.

|

|

|

| Variant of colors in the photograph – typical, it is possible to paint to order | Italian filter WAM is installed on the roof of the silage | At the top and lower, level sensors are installed, electrical wiring is done |

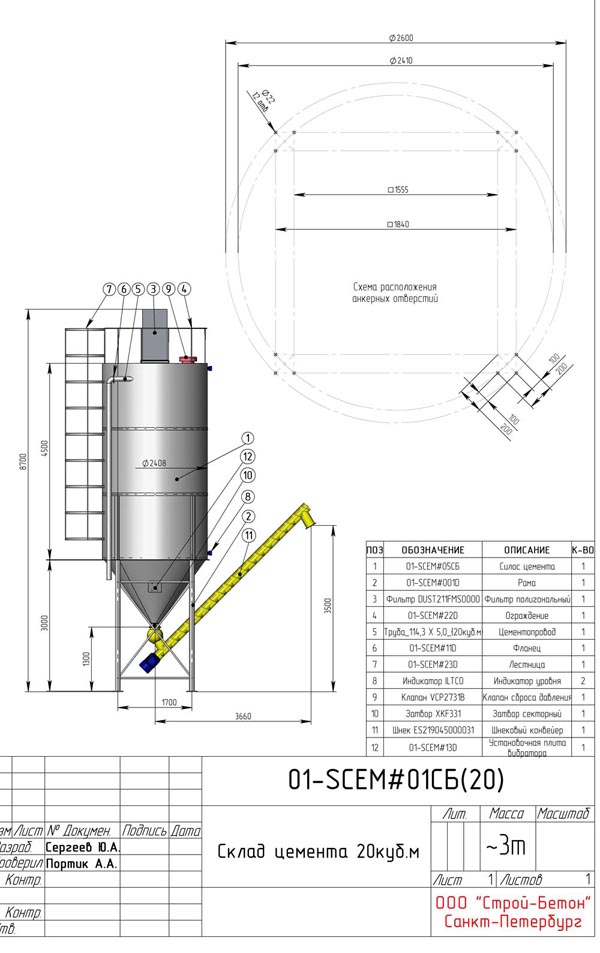

Cement warehouse

The delivery set includes:

- Cement silage

- Standard output support structures

- Loading pipe

- Service site, staircase and fences

- A primer for transportation (silos coloring is ordered separately)

A pneumatic feeder or an inclined strip conveyor is used to load cement into the silage, for unloading – a pneumatic pump or a screw

conveyor.

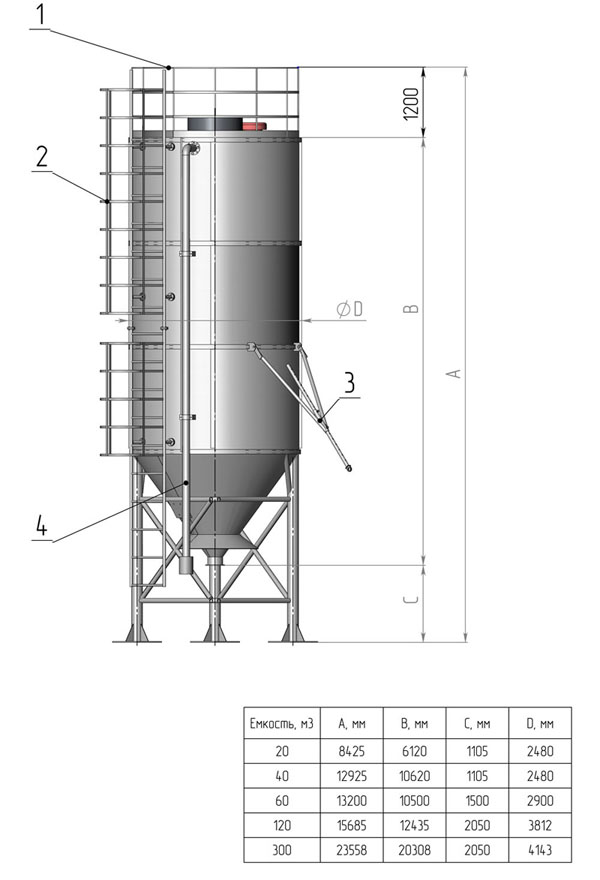

Typical volumes and models

In our company you can buy a silage for storing cement with a volume of 8 to 300 cubic meters. m. The weight of the stored cement is calculated depending on the volume:

- 8 cubic meter. m. – 10 tons (diameter – 2.4 meters, height 5 meters, mass 2 tons).

- 20 cubic meters. m. – 26 tons (diameter – 2.4 meters, height 8.5 meters, weight 3.75 tons).

- 40 cubic meter. m. – 52 – tons (diameter – 2.4 meters, height 13 meters, weight 5.5 tons).

- 60 cubic meters. m. – 90 tons (diameter – 2.9 meters, height 13.2 meters, weight 8 tons).

- 120 cubic meters. m. – 156 tons (diameter – 3.8 meters, height 15.7 meters, weight 12 tons).

The advantage of our products is an affordable price for stains for cement with high quality.

Cement Silos drawing

Additional equipment and options

The list of additional equipment is agreed with the customer and mounted on silage when it is installed.

- Painting in the color chosen by the customer (up to 3 colors per sir) – 28,600 rubles. It is possible to apply inscriptions, logos, etc., stipulated additionally. (If painting is not ordered, then be sure to paint on the spot to protect against corrosion)

- Rotal valve (WAM, Italy).

- Silosa safety valve (WAM, Italy).

- Air filter (WAM, Italy).

- Level sensors (WAM, Italy).

- Aeration jet (WAM, Italy), you need 6 pieces per silage, and more than 40 cubic meters are required on devices. m.

- A screw conveyor for cement 5 meters (WAM, Italy).

Features of the products of the factory Stroy-concrete

Stio of the Stroy-Beton plant is highly of high quality, reliability, durability, thoughtfulness of the structure and excellent appearance. The sale of both typical silos for cement and on an individual order is carried out.

Our silos is certified, certificate of conformity.