Anti -crisis proposal from the Aamix plant on the False False line

We have been producing equipment since 1998, for more than 20 years. During this time, our clients became many companies, including industry leaders – KNAUF, Gazprom, Norilsk Nickel, Hess AAC (Holland).

Our company is a plant with a full cycle of metalworking – from its own industrial laser cutting Trumpf metal, ending with assembly, coloring, etc.

We manufacture the main equipment (silos, mixers, packaging) in our own production in the city of Sank-Petersburg.

We use the components WAM (Italy), whose official representative we are, UWT LEVEL (Germany), CAMOZZI (Italy), Tenzo, Aries.

- The news about our package, which was set in 2016 and then the client ordered additional in 2022.

- News about the installation of packing.

- News as a client ordered a package from us instead of another manufacturer purchased from another manufacturer.

And so we have prepared the most profitable offers for you, ready -made business: packing fertilizers in bags.

See also:A set of equipment for packing fertilizers, feeds, chemicals in open bags FASOM2.

1. Fertilizer packing line “Smart”

Compound:

-

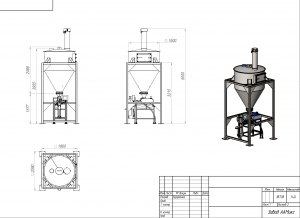

Reception hopper for packingvolume 2 m3., on the frame.

In the kit:

– throttle valve 300 mm with manual drive

– FilterAerklin Smart2, galvanized case

– aircraft set for 3Vibrovalrators24DC - Installation for packing fas-km2 rotor.

FASS FAS COM2 Rotor is highly capacity up to 10 tons per hour and complete automation. This installation faces fertilizers in valve bags in the range from 10 to 50 kg.

To order and calculate the cost, writeinfo@isilos.ru,Telegramhttps://t.me/aamixruor call tel.: +7 (812) 408-41-82

2. Line “Optima”

The Optima Packing line is an economical solution for your business, which allows for the shortest possible time, as well as without significant investment to supplement the range of products you have produced or organize a mini production for packing fertilizers in valve bags from 10 to 50 kg.

The package line of our production includes the most optimal set of equipment and consists of:

- Silos with a volume of 20 cubic meters. With a complete binding that includes: a) the silos filter Aerklin Medium, a galvanized case, pr-in aamix.b) a safety spitting spring valve B) lobed levels of aeration system on the basis of 8 aeration jet of jukler d) disk shutter D 300 with manual drive

- Installation for packing fas-km2 rotor.

FASS FAS COM2 Rotor is highly capacity up to 10 tons per hour and complete automation. This installation faces fertilizers in valve bags in the range from 10 to 50 kg.

- Acadricious station Aerklin Hard 1.

The installation consists of a filter of fine cleaning with automatic pneumatic cleaning of filter elements, an extract and a bunker for collecting dust. The submarine aspiration station is necessary in production to comply with environmental standards.

To order and calculate the cost, writeinfo@isilos.ru,Telegramhttps://t.me/aamixruor call tel.: +7 (812) 408-41-82

3. Line “Optima Plus”

The Optim Plus Packing line combines the efficiency of the Optima mini-production and thanks to the silage of an increased volume of 40 cubic meters. It allows you to reduce transportation costs, since a silo of this volume allows you to completely unload the cement carrier.

The phasing line “Optima Plus” includes:

- Silos with a volume of 40 cubic meters. With a complete binding that includes: a) the silos filter Aerklin Medium, a galvanized case, pr-in aamix.b) a safety spitting spring valve B) lobed levels of aeration system on the basis of 8 aeration jet of jukler d) disk shutter D 300 with manual drive

- Installation for packing in bags Fas-km2 rotor.

FASS FAS COM2 Rotor is highly capacity up to 10 tons per hour and complete automation. This installation faces fertilizers in valve bags in the range from 10 to 50 kg.

- Acadricious station Aerklinn Hard 1.

The installation consists of a filter of fine cleaning with automatic pneumatic cleaning of filter elements, an extract and a bunker for collecting dust. The submarine aspiration station is necessary in production to comply with environmental standards.

To order and calculate the cost, writeinfo@isilos.ru,Telegramhttps://t.me/aamixruor call tel.: +7 (812) 408-41-82

4. Lux “luxury” line

The luxury packing line is a price ratio, since, unlike the Optima mini-production, it allows you to make the process of packing the product more automated, which reduces the losses possible for damage or falling bags.

Mini-production “Lux” consists of the next equipment:

Mini-production “Lux” consists of the next equipment:

- Silos with a volume of 40 cubic meters. With a complete binding that includes: a) the silos filter Aerklin Medium, a galvanized case, pr-in aamix.b) a safety spitting spring valve B) lobed levels of aeration system on the basis of 8 aeration jet of jukler d) disk shutter D 300 with manual drive

- Installation for packing fas-km2 rotor.

FASS FAS COM2 Rotor is highly capacity up to 10 tons per hour and complete automation. This installation faces fertilizers in valve bags in the range from 10 to 50 kg. - Aspiration block based on Aerklin GB 500 and Aerklin Hard 1.

Aspiration block is air purification in production in 2 stages: 1) rough (aspiration station based on cyclone GB 500) b) thin (aspiration station Aerklin Hard 1).

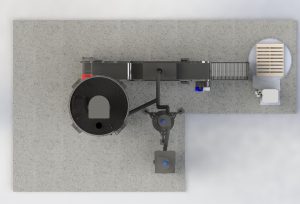

Which allows you to extend the service life of cartridges, as well as comply with environmental standards in production.  A strip conveyor for serving bags with a dug and a squeezer of the bag.

A strip conveyor for serving bags with a dug and a squeezer of the bag.

The strip conveyor is designed to automate the packaging process into valve bags. The packing station automatically supplies the bag onto the conveyor, in the subsequent the bag is rolled and advisers to the boxing box for further supply to the production process.- Rollerg.

Rollerg is designed for a safe piece of bags, as well as to reduce the percentage of marriage (damage to the bag) in the process of packing the product. - Universal Pallet Pacific in a Stretch film.

Packaging equipment designed for winding and fixing cargo on the pallet by means of a stretch. Such devices quickly and gently perform the winding with a film laid on the pallet of the cargo.

To order and calculate the cost, writeinfo@isilos.ru,Telegramhttps://t.me/aamixruor call tel.: +7 (812) 408-41-82

Additional information

1. What installations are facing fertilizers in the bags – comparison and choice

The package is carried out by rotor-pneumatic installations of the Sunmyx FAS CMM. For fertilizers, two KM2 and KM4 installations are suitable. Both installations are faced with fertilizers in valve bags and can be used in any lines. Outwardly, they are very similar, but there is a constructive difference and performance difference.

Comparison of parameters

| Parameter | Packing Fas-km2 |

Packing FAS-KM4 |

| Detailed description | Isilos.ru/fas-km2.php | Isilos.ru/fas-km4.php |

| performance | up to 120 bags per hour | up to 300 bags per hour |

| The location of the rotor | Vertical | horizontal |

| Simplicity service | Just | difficult |

| DOSION accuracy | +-250 grams | +-250 grams |

| speed | Two (main and slowed at the end of the package) | Two (main and slowed at the end of the package) |

| Formation speed adjustment of 1 and 2 speeds | Yes | Yes |

| air adjustment | Manometer | Manometer |

| control | Touch panel + Aries controller | Touch panel + Aries controller |

As you can see from the table, the main difference between packs in performance. Prices for packages can be viewed inPrice list.

About control features and packs of packagesYou can read the news >>

2. What is needed besides the installations for organizing packing

The answer to this question depends on several parameters:

- How fertilizer is supplied to the enterprise – in BIG -bugs or cement trucks or pneumatic transport from wagons

- What performance is needed

- In what bags will the packing take place – 50 kg, 25 kg, ….

- How planned to pack packaged bags

Depending on this, the installation of packing and related equipment is selected. In principle, two main common cases can be distinguished – fertilizer enters the Big Bigs or fertilizer enters the silage at our enterprise from cement transport or carriage.

Prices

Fresh prices for all equipment are inPrice listOr writeinfo@isilos.ru,Telegramhttps://t.me/aamixruOr call tel.: +7 (812) 408-41-82 and we will make you a detailed offer and help you with the choice of equipment.

Video how the packaging works

In the video you will see a slight dusting, since the package in test mode is not connected to aspiration (hood). When working as a package, it is imperative to connect it to aspiration and air purification, for exampleCyclone TsN-15.