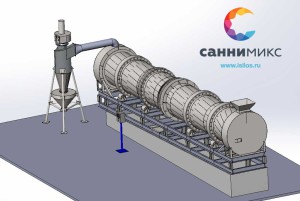

Drying drums for sand and clay are produced by the Aamix plant and are used at enterprises for the production of dry building mixtures or on the bearing lines of various bulk materials.

Drying drums for sand and clay are produced by the Aamix plant and are used at enterprises for the production of dry building mixtures or on the bearing lines of various bulk materials.

The drum is designed to drain wet sand or other bulk material and its subsequent use in the production of dry building mixtures or packaging.

Drum performance from 3 to 50 tons per hour. Drums are produced in modern production at the famous Aamix plant for more than 11 years and have been successfully working throughout Russia and abroad. The places where our drums work – Yamal LNG, Gazprom, Norilsk Nickel and many others. At the same time, the prices of our drums are available to medium and small businesses, and reliability satisfies the most demanding customers. We completely produce everything at our factory, from laser cutting and ending with assembly and painting.

View our report on Baltimix 2024 about drums.

Our drums work on 4 types of burners

- Gas burner

- diesel burners

- unique coal, development of Aamix, Russia (The news about our drum on the portal “made with us.”)

- unique electrical, development Aamix, Russia

Video work of our drying line of sand 5 tons per hour (Gatchina, St. Petersburg).

Device and principle of operation

The drying drum consists of a metal cylinder, with special guides inside, covered on the outside with a heat -insulating coating, a drive for rotating the drum and burner.

The sand is supplied to the beginning of the cylinder and at high temperature passes through it and is issued from the opposite side.

Due to this, the sand or any other bulk material is drained.

It is equipped with a gas or diesel burner (or coal furnace or electric heaters):

- See the price for a standard drum in the price list.

- View photos of the mounted drum at the factory in Kaliningrad.

Send a request online

Complete

Included in the price

- Drying drum, steel 09g2s;

- Rama with a drum rotation drive –All -metal star – See news;

- Control panel;

- Reception and unloading bunkers;

- Automation of the burner control and temperature control;

- Drum insulation;

- Thermal battery (core)

Not included in the cost

- Cyclone TsN-15With a centrifugal fan and a dust collection container (performance depends on the performance of the burner, comes with an industrial reliable fan). It is required if there is no system of air stretching

- Schneider frequency regulator (industrial), sometimes you need to configure rotation speed to your material and current humidity- from 20 to 50 kW, depending on the drum

Depending on the type of fuel and productivity of the drum, a burner and a type of fuel are selected. The cost of the burner is not turned on.

Design

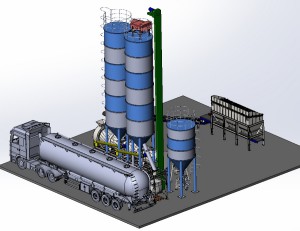

Typically, the drum of sand drying is installed at enterprises producing dry mixes or other building materials. Before installing it and production, it is necessary to make a placement project in which should be taken into account:

- The size of the room

- Where the sand is unloaded

- sand supply method to the drum

- The method of serving dried sand for storage

Our engineers have extensive experience in such projects and we create full 3D placement models, after which we produce equipment in accordance with the project.

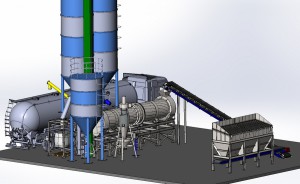

We also produce all auxiliary equipment – cyclones, hoods, sand supply conveyors, filters, etc. And we can completely professionally design and compare your line.

Examples of projects (all projects are laid out on flat drawings with accurate dimensions)

|

|

|

News about shipping

- some advantages – photos from shipping in a boil with explanations

- Photo report on the launch of the drying line with a drum on a coal in Abakan

- Photo report from the plant in Kaliningrad, drying 25 tons per hour

- Shipment for the SCS plant to Holland

- Shipment for the Yamal LNG project(a large project for the development of a gas field)

- News about the shipment of a drum 25 tons per hour(Large plant for the production of CSC in Dagestan)

- The news about our drum on the portal “made with us”

Burners

- Diesel or gas – the Lamborghini burner – is selected based on the productivity of the dryer

- Coal – classic firebox, firebox power is selected for performance

- Electricity – for drums of 5-10 tons per hour, you can make heating with heating elements, power 500 kW, 50 heating elements of 10 kW, special design

Additional equipment

- Enlarged

- Bunker for acceptance of sandfrom dump trucks or loaders and conveyors for supplying sand to the dryer

- Bucket elevatorto transmit hot dried hot sand to silos

- Vibrogrokhotfor dispersing dried sand in the fraction

- Ribbon conveyorsfor supplying sand to the drum

The AAMIX plant supplies not only individual drums, but also ready-made complexes for drying and dispersing materials into different fractions, packing installations for packing sand or other bulk products in bags or beig-bugs.

Technical characteristics

For drums from 20 to 50 tons per hour, projects are done individually. To calculate the drum, data on the material, initial humidity, fuel for heating, etc. are used.

|

Drying productivity |

Drying productivity 5-10 tons per hour |

Drying productivity 10-15 tons per hour |

Drying productivity 15-20 tons per hour |

|

|

Dimensional dimensions (DHSHHV), mm |

5300x1400x2107 |

8000x1400x2107 |

8000x1900x2800 |

1000x1900x2800 |

|

Mass, kg |

2500 |

4000 |

6500 |

8000 |

|

Revolutions per minute |

8-9 |

8-9 |

6-7 |

6-7 |

|

Power voltage, c |

380 |

380 |

380 |

380 |

|

Electric power, kW |

5.5 |

7.5 |

11 |

11 |

Photos of a drum dryer for sand at the SSC factory

Drawing of the drum

Buy online

Technical documentation

Certificates

Our equipment undergoes voluntary certification + we receive declarations of conformity, which is necessary to register your production in various instances.