The Aamix plant produces, sells and supplies automated, reliable lines for the production of dry building mixtures under the AAMIX brand.

The Aamix plant produces, sells and supplies automated, reliable lines for the production of dry building mixtures under the AAMIX brand.

We are a plant with a full cycle of metal processing -from our own laser cutting of the metal to the production of assembly, powder color, etc.

The main equipment (silos, mixers, packaging, dispensers, conveyors, etc.) we manufacture in our own production.

Components for silos, feeders use the Italian company WAM, whose official representative we are. Pneumatics Camozzi (Italy), control panel based on Aries automation (at the request of Siemens – only in price).

The algorithm for working on the plant

- The development of an individual project of the plant includes, if necessary, the departure of our specialist to the place, consultation, the plan of equipment, 3-D modeling of the plant, a set of drawings. It takes from 2 to 8 weeks.

- Manufacturing equipment according to the agreed project. The term is from 1 to 8 months, depending on the load, volume and complexity.

- Launching equipment from 2 to 10 weeks.

Automation of factories

We ourselves produce robots at our full cycle plant in St. Petersburg. We solved one of the key problems of the plants of dry mixtures – complete automation of the bearing unit.

The fully automatic packing node consists of:

- Installations of packing in valve bags.

- A robot of putting bags on packages.

- A robot of laying bags with a mixture on the pallets.

We produce packages and robots. For programs, industrial controllers with open programming language are used, which makes the service simple and reliable.

Dosage to the mixer:

We also solved the task of automatic microdation – for more than 10 years, a permanent client of our solutions is the KNAUF company and many others. Adders from bags are automatically dosed into the mixer without human participation. Including fibrous and sticky additives.

Conclusion.

If you need a reliable and fully automatic plant from a Russian manufacturer with a large history, then we are your choice. Everything is produced in Russia, our reference list is huge, we produce robots and write programs for them. We are the participants of Skolkovo. And we will be happy to build your from the factory from the project to the launch and the first parties.

Our clients

Among our customers are not only Russian, but also well -known foreign manufacturers. We successfully compete in the international market and supply plants to large enterprises of the construction industry.

- Aerostone dry mixtures plant (news)

- Contite Seal waterproofing plant (news)

- Klester dry mixing plant (news)

- OJSC Gazprom – a CSC production plant with vermiculite, turnkey delivery. (news)

- Hess AAC is a manufacturer of large factories of autoclave aerated concrete. One complete plant was delivered for installation in Libya. (news)

- KNAUF – this well -known brand constantly acquires various components, complete production from us, and also orders the development and production of unique systems. (News 1, News 2, News 3)

- Petroperlit, St. Petersburg – a unique plant with Petrooperlite, a factory of 15 tons per hour (news, Gratitude for the installation)

About us in the press, installation reports

- News about financing the production of the plant of Siemen-Finance

- News about a line of 300 tons of packaged mixtures per shift, Nizhny Tagil, the company “Sands of the Urals”

- Photo report on the installation of a complete plant in Kaliningrad

- About starting the plant in St. Petersburg, on the portal made with us

- Full report – from drawings to shipment at a complete plant in Vologda

- Client’s review about urgent modification of imported packages

Send a request to the factory online

Important information

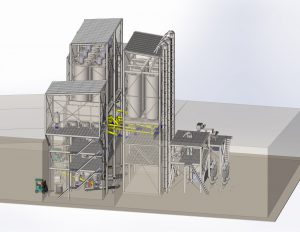

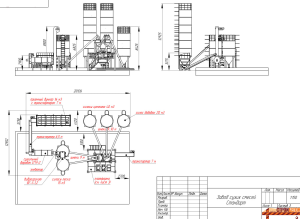

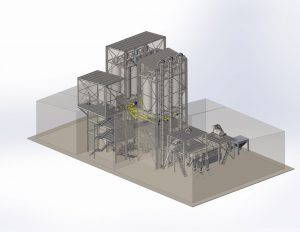

IMPORTANT!For each customer of the plant of dry building mixtures, its own 3D model is created completely for specific needs. After that, the model is laid out into flat drawings and on them the equipment of dry mixtures is installed at the facility.View models of factories in different layouts.To speed up your work on your project, you can fill out a questionnaire or you can do this with our managers by phone.

Typical sets

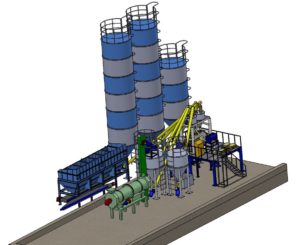

Logically, plants are divided into two different options – vertical and horizontal.

With a vertical design of the silage or other drives are above the dispensers and therefore, to transfer the components of mixtures to weight dispensers, screw conveyors are not needed. This is a plus, since screw conveyors require periodic maintenance and replacement of the wear of wear. The disadvantage of this layout is that the design of a large height is required, which is not always possible.

Horizontal performance can be placed in rooms with a relatively low ceiling height. The only disadvantage of this scheme is that it requires additional equipment for the transfer of materials – screws or pneumolines.

Horizontal performance can be placed in rooms with a relatively low ceiling height. The only disadvantage of this scheme is that it requires additional equipment for the transfer of materials – screws or pneumolines.

Below is a list of typical options for factories, but each order is unique and calculated separately.

To calculate the price, writeinfo@isilos.ruAnd we will make an offer for your needs.

You can alsoDownload a booklet with a description of factories and lines of dry mixtures.

| Name | Description |

| Vertical 1 | performance up to 10 tons per hour |

| Vertical 2 | performance up to 30 tons per hour, without drying sand |

| Vertical 3 | performance up to 30 tons per hour, with drying sand |

| Horizontal 1 | performance up to 10 tons per hour |

| Horizontal 2 | performance up to 30 tons per hour, without drying sand |

| Horizontal 3 | performance up to 30 tons per hour, with drying sand |

Compositions of the CCC

Automation and control system

Automation for each plant is made its own, the plants are fully automatic, management with industrial touch. Panels, monitoring via the Internet, data transfer to 1C accounting is also possible.

Variant of a typical line for the production of dry mixtures

The AAMIX plant supplies lines of greater performance for more types of dry mixtures. Large projects are prepared individually on request and after filling out a detailed questionnaire.

The Aamix line allows a wide range of dry building mixtures. The basic configuration provides for production:

- Plaster mixture

- Glue for tiles

- Pantry

- Glue for aerated concrete \ foam concrete

- Self -leveling mixtures

Line performance from 3 to 30 tons per hour.

Materials

Materials used in production, for which there are drives and gear rates in the basic configuration (it is possible to increase the number of materials):

- Cement

- Sand with grain size 0-0.6mm

- Little milk is thin

- Quartz ground, dusty faction

- Additives – methyl cellulose, starch broadcast, copolymer polyvinyl acetate

The percentage of the consumption of components per 1 ton of the produced dry mixture (adhesive for tiles is taken as an example).

|

The component of the mixture

|

Know-kg |

Top |

|

Portland cement is unreasonable (M-500) |

280 |

28 |

|

Little milk is thin |

30 |

3 |

|

Quartz ground dusty fractions less than 0.08 mm |

35 |

3 |

|

Quartz sand – 650 kg |

650 |

65 |

|

Copolymer of vinyl acetate and ethylene – 3 kg |

3 |

0 |

|

Eir of cellulosa high -skinned -modified starch ether |

2.2 |

0 |

From the table above, it is clear that the main materials consumed are cement and sand. The remaining components are consumed in small quantities. Next, day and monthly consumption with a performance of 50 tons of dry mixtures per day are given.

|

The component of the mixture |

Top to the cube, kg |

Day consumption, with a volume of 50 tons per day, kg |

Month expense, 22 working days, tons |

|

Portland cement is unreasonable (M-500) |

280 |

14000 |

308 |

|

Little milk is thin |

30 |

1500 |

33 |

|

Quartz ground dusty fractions less than 0.08 mm |

35 |

1750 |

38.5 |

|

Quartz sand – 650 kg |

650 |

32500 |

715 |

|

Copolymer of vinyl acetate and ethylene – 3 kg |

3 |

150 |

3.3 |

|

The air of cellululose is high -skinned -modified by the air of starch – 2.2 kg |

2.2 |

110 |

2.42 |

We get that with this production per day, 32.5 tons of sand and 14 tons of cement per day are consumed per day, the remaining components are consumed in a small amount.

When planning and designing the plant, it is necessary to take into account all the options for the produced dry mixtures in advance in order to plan the necessary bunkers and silage for storing components, the necessary parts of the weight system, the configuration of the production program, etc.

All this is carried out by the specialists of the Aamix plant. When supplying and production of a line of dry building mixtures, we take responsibility from the design stage, to the stage of installation, launch, production of the first batches of products.

Aamix factory – support in support!

Competitive advantages of the line

- High degree of automation using Aries controllers, siemens.

- The finished mixture can both be bending in bags, or to be given directly to a car cement car.

- Different options for receiving and issuing materials are possible.

- All components of silos and screws are produced by WAM, Italy and are delivered directly, which guarantees low prices.

Circulation of materials in the line SB-6000:

- Cement is stored in cement silos (from 20 to 120 cubic meters), supply to silage from a car cement truck (it is possible to supply larger silos and the reception of cement from the Khopov wagons). From silos, cement is supplied to the dosage of screws.

- The remaining components are stored in silos 10 cubic meters, which is about 8 days of work enough

- Sand can be accepted and stored in several ways:

- It is taken from dump trucks to the floor, then served by the front loader to the bunker of the sand

- It is accepted from dump trucks to the receiving bunker, do not need front loader, but you need to make a large installation pit for the hopper, which can be more expensive than a loader. And the loader in the production is always useful not only for sand, but also for other needs.

- From the bunker of sand, sand is supplied to the drying drum, then on a dawn in fractions and further into storage bunkers. From storage bunkers, sand is supplied to dosage.

- Addments are dosed manually through a special neck.

- After dusias, all components are fed into the mixer with a capacity of 1 cubic meter.

- From the mixer, the finished mixture is transferred to the receiving hopper.

- From the receiving hopper, the mixture is either packed into valve bags or is supplied directly to the car cement car.

The composition of the base line (when creating mixtures with sand)

- The cost of typical lines can be viewed in offers, the links to the download of which are given at the beginning of the page.

- The basic equipment can vary greatly depending on the tasks and premises of the customer.

|

|

Description |

Top |

|

1 |

Silos cement 60 cubic meters (Silos delivery includes: silage, fences, stairs, racks, pipe of cement pumping, primer.) |

1 |

|

2 |

Silos Cement 10 cubic meters (Silos delivery includes: silage, fences, stairs, racks, pipe of cement pumping, primer.) |

3 |

|

2 |

The acceptance line of sand from dump trucks and its transfer to the weight measuring complex. Without scattering into the fractions. |

1 |

|

3 |

Sand drying line with scattering 3 fractions |

1 |

|

4 |

Binding of silos |

4 |

|

5 |

Switching conveyor 6 meters for supplying cement from silos for a dose. (production of WAM Italy) |

4 |

|

6 |

Weighing DOSISE |

3 |

|

7 |

Mixer of dry mixtures Prof-SC 1000 |

1 |

|

8 |

The deglomerator for the mixer, type of tulip, production of WAM, Italy |

2 |

|

8 |

Metal structure of the complex – support of the mixer, stairs, service sites, fences. |

1 |

|

9 |

The capacity of the mixer mixture |

1 |

|

10 |

8 meters screw for supplying the finished dry mix in cement carrier |

1 |

|

11 |

4.7 meters screw to serve the finished mixture in the packaging line in bags |

1 |

|

12 |

Automatic line of packing in bags of 5-50 kg. With a reception hopper 1 kub.m., a performance of 10 tons per hour, complete with a 5 meters submarine for issuing bags |

1 |

|

13 |

Central control panel |

1 |

The composition of the line may vary in the direction of reducing the number of equipment by reducing the drying section and preparation of sand, a decrease in the amount of silos and screws or towards the increase due to greater automation and the amount of silos for components.

The usual period of shipment after concluding a contract and the first prepayment is 5 months.

Delivery is made from St. Petersburg, to deliver a full set you need 6 long trucks 24 tons.

Installation of the plant can be carried out by the supplier, the cost of installation is calculated separately and depends on the list of work performed.

Video from a working plant 1

This video was filmed in the fall of 2015 at the factory installed in St. Petersburg. The plant worked from May to October with a performance of 30 tons of a mixture per hour. The plant was created by our company from a unique project and ending with the chief installation and production of the first parties.

Video from a working plant 2

This video was shot by our client, to whom we developed the project, produced all the equipment and made the installation of the plant. The video was made in 2019, in 2020 the plant has been operating for the fifth year.

Clients are constantly in touch with us, we make additional modules, supply spare parts, serve equipment.

Line drawing on the plane

View models of factories in different layouts.

Send a request to the factory online

A map of the factories and iconic projects we have done

Among customers, you can see both KNAUF units (Danogips), Gazprom, Norilsk Nickel and other large enterprises, as well as plants built by private business to cover the needs of dry mixtures in small cities and regions.

We are proud that many cdins have been with us for more than 10 years and constantly order new equipment. We constantly improve quality, make high -quality drawings for each project, completely accompany all the documentation all the equipment.

Our clients

Among the customers of the Aamix plant are such large companies as:

|

Designed and put a full line of components to the plant of dry mixtures.News with a photo. |

|

For the production of dry mixtures under the Klester brand, we built a complete plant in Kaliningrad.Project and installation report. |

|

|

OJSC Gazprom – We developed, manufactured and put a fully automatic plant for the production of dry mixtures. The plant is designed to work in the Moscow region. (News 1, News 2) |

|

|

KNAUF company is a world -famous, large manufacturer of putty and dry mixtures. For them, we produce a system of automation, dosage, customers, silage, etc. (News 1, News 2) |

|

On May 22, 2015, a contract for the construction of the plant for the production of waterproofing materials of the Cormix brand was signed between the company LLC Kormix LLC and Cormix International Limited. |

|

Hess AAC Systems (Holland) – a complete factory for Europe has been delivered. (News 1, News 2, News 3) |

|

| Aerostone gas concrete plant – developed, made and launched a complete line for the production of dry mixes at the factory of autoclave aerated concrete (Client website) |

And also more than 500 customers throughout Russia and the world!View reference listWith key customers.

Recorded striming – plants of dry mixtures: composition, main layouts.

Since this is streaming, the quality of the recording “Living”. However, our chief engineer told many nuances and answered questions from the comments.

Mobile plants of dry mixtures

We also produce mobile factories. They can be quickly installed in any area. The simplicity of transportation, installation / dismantling is achieved due to the modular structure and that all modules consist of sea containers.