The paper bags of paper bags is developed at the Aamix plant for industrial enterprises and is a modular design that can be equipped with various additional devices at the request of the customer.

The shust solves an important problem of the safe molting of chemical additives to the storage bunkers, from where they are further transferred to the mixer or other production chains.

More

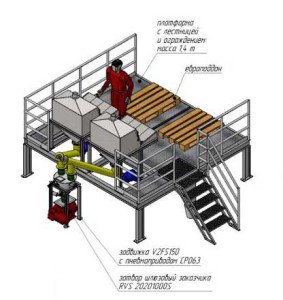

It is possible to feed the material from bags to a screw or to a pneumatic machine or a dispenser with preliminary weighing and accounting of the material.

It is possible to feed the material from bags to a screw or to a pneumatic machine or a dispenser with preliminary weighing and accounting of the material.

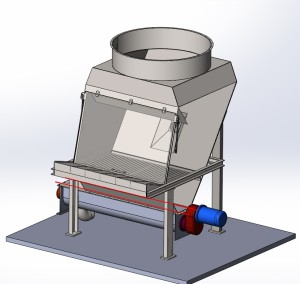

The basic design of the shust is a module of moltening on the legs with a convenient feed height and the material feeding system down. Protection is provided against large lumps.

An exhaust filter is usually installed above the member or a aspiration line is connected to protect people from dust.

The lower part of the shust is equipped with a convenient flange and the ability to fasten various transmitting equipment.

- Download description in pdf format

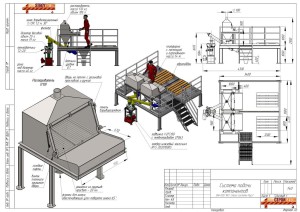

- Download drawing with overall dimensions

- Download price with a price for a molester

Clients

- Photo report from the client’s factory after a year of work.

- The news of the shipment in polyplast with the photo.

- The news about the development and supply to KNAUF.

- Photo of the molester at the production of KNAUF.

- The news of the shipping of the member with the photo.

Competitive advantages and features

Competitive advantages and features

- Standard reliable places of tensoport

- Reinforced, durable design

- built -in aspiration, ready output, you just need to connect to the system

- Ready lower flange for connecting a screw or pneumatic system

- Our equipment is certified

Technical characteristics

|

Gabarit dimensions, DHSHHV, mm |

1200x800x1500 |

|

Weight, kg |

900 |

|

Weight measurement accuracy (in configuration with tensodists) |

+-1kg |

|

Maximum load, tons |

0.5 |

Additional options

- Tensodists for weight measurement

- Weight display remote + transfer of information about weight to the central computer

- The transmission of the powder from the member is possible in ways:

- Schnek transporter

- Transfer to the pneumolinum using the RV sector shutter and a special dispersion module when serving in pneumatic machine

- Pissing with a pneumatic pump

When ordering a binder, the best option is discussed and our engineer helps to choose the necessary equipment.

Model of a detailed

An example of a project with weight measurement and transfer to pneumatic massagistral

You may also need: