The installation for packing fas-km4 is designed for packing bulk materials (cement, flour, microcracks, dry mixtures) into valve bags.

The installation for packing fas-km4 is designed for packing bulk materials (cement, flour, microcracks, dry mixtures) into valve bags.

This installation is the most productive and accurate in a series of packs in valve bags.

Initially, to create this package, a sample of package made in Germany was used for the KNAUF plant. After that, the package was finalized:

- The accuracy is increased due to the use of two independent frames: frames with an installed rotor and frame with an tensod.

- increased performance by changing the rotor to a more modern

- The installation was fully automated on Aries controllers

- Reliability is increased through the use of automation with a higher degree of protection

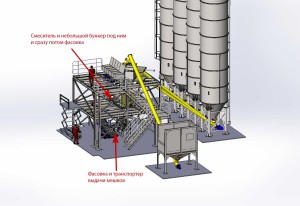

IMPORTANT! One of the unique features of this model is that the speed of the package remains with a low column of a dry mixture in the bunker. That is, you can connect the installation to the bunker directly under the mixer, which is important when placing production in a room with limited height.

Now these installations work at factories in Russia and abroad.

News about packaging from customer production

- Gazprom (Moscow) is a high -performance plant, dry mixtures with vermiculite.See the news.

- Petroperlit (St. Petersburg) – a plant for the production of dry mixtures with perlite, 15 tons per hour.See the news.

- Hess AAC (Holland) – a factory of classic dry mixtures, 15 tons per hour.See the news.

- Shipment of the third package in Vladikavkaz. + News about installation in the same enterprise.

With all the pluses, the installation cost is quite competitive, through the use of Russian controllers and the full production cycle in Russia.

Important! There are very cheap packs on the market, but they do not work and, as a result, quite a few manufacturers contact us with a request to repair, set up or replace the purchased packages.News with a photo about replacing the packaging of another manufacturer.

Send a request to Fas-km4 online

The principle of action

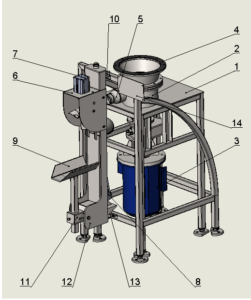

The installation consists of a bunker in which the faculty material is located, the rotor of the supply of material into the valve bag and electronic weights.

On the control panel, the weight is set once, which must be put in the valve bag, after which the installation works automatically in the cycle:

- The operator puts on a bag

- The clamp is automatically triggered

- The package begins

- When the desired weight is reached, the packaging stops

- The clamp is automatically opened

- The pusher automatically works and the bag moves to the supply conveyor to the pallet

- The operator puts on a bag

- …..

That is, the operator only needs to put on a bag.

Our control panels are very thought out and controlled from the touch of the panel. You can configure the speed of packing, accuracy, air operating mode, keep records of shifts and much more.A detailed description here.

Competitive advantages

- Simplicity of management

- Reliable automation of Aries of Industrial Execution

- Complete automation and understandable control

- Fast and competent technical support from the manufacturer

- Guaranteed installation quality tested on many large SSC factories

Control panel

Our control panels allow you to very flexibly set up packaging to different operating modes and different materials. Big and reliable touch. The screen allows you to see all the data and quickly reconfigure the package to new recipes.

Also, data can be transferred to the central control panel and further to the MES, ERP system.

Technical characteristics

|

Characteristic |

Es-ts. |

|

|

Bag of bag 25 kg |

seconds |

from 5 to 10 |

|

Length, width, height |

mm |

720x1400x1540 |

|

Weight |

kg |

260 |

|

The supply voltage |

IN |

380 |

|

Engine power |

KW |

5.5 |

|

Productivity (approximately) when packing cement in bags of 30 kg. With a valve width 11 cm: |

Tons \ hour |

from 5 to 15 (you can configure the necessary) |

|

The width of the bags used |

cm |

30-50 |

|

The length of the bags used |

cm |

40-70 |

|

Valve width used bags |

cm |

11 (9) |

|

Dose |

kg |

10-50 |

|

The accuracy of packing |

% |

0.1 |

|

Type of bags (packaging containers) |

– |

valve |

|

Requirements for the external source of compressed air (compressor) |

MPa |

0.7 |

|

Requirements for the external source of compressed air (compressor) |

m3/min |

0.3 |

|

Requirements for the system of aspiration (discharge) |

M3/hour |

from 1000 to 2000 |

Options

-

-

- If a mixture with a density of less than 1000 kg. \ Cub. M. Complex:

The throttle shutter is 80mm – 7600 rubles.

Pneumatic drive CP101 – 10800 rubles.

Pneumatic distributor V5V80 – 5200 rubles.

Mic23 position sensor – 3500 rubles.

When this valve is connected to the control panel, the tracking and automatic opening option \ closing this valve is activated. That is, nothing needs to be adjusted additionally, everything is already in the package algorithm. - Flat strip conveyorFrom 5 to 10 meters to supply bags from installation to the packaging on the pallet.

- System of aspiration based on the Wamflo filter (Italy).

- Switch conveyorFor the supply of cement or a mixture from the hopper to the package.

- Big-beags moltening system.

- If a mixture with a density of less than 1000 kg. \ Cub. M. Complex:

-

Installation installation

The installation is mounted directly under the hopper with a dry mixture or silage with cement or other bulk material.

To be able to service the installation between it and the hopper, the valve is always installed.

The standard installation location scheme on the model of a real plant is lower.

Photo with an example of installation installation

Automatic putting bags

Packing KM2 and KM4 can be equipped with installations for automatically putting on bags.

This solves the main problem of production of dry building mixtures – the operator’s work in difficult conditions.

Productivity also grows significantly. In the video, the work of our packaging with automatic putting bags at the factory of our client.

Video from a working factory

This video was filmed in the fall of 2015 at the factory installed in St. Petersburg. The factory operates two of our packages with a capacity of up to 15 tons per hour in bags of 30 liters.

What else to read?

-

-

- Comparison of packageswith an algorithm of work, weighing, etc. –We recommend reading!

- Cement package– An article about how to organize it.

- Details with photos about the package control panel.

-

Other types of packs

-

-

- All equipment for packing produced by our plant.

- FAS CM2 Rotor– Less productive than this, cheaper.

- FAS COM3-Pneumo– completely pneumatic, for fragile or large materials (perlite, expanded clay, etc.).

- FAS-1– for packing crushed stone in plastic bags.

-

Concomitant equipment

-

-

- Ribbon conveyors– for bags or bulk materials.

- Cyclones– For air purification, be sure to pack.

- Silos– for storing the source materials.

- Fluckers of dry mixtures– for preliminary mixing of several materials.

- Factories of dry mixtures– for industrial production of dry building mixtures.

-

Send a request to Fas-km4 online