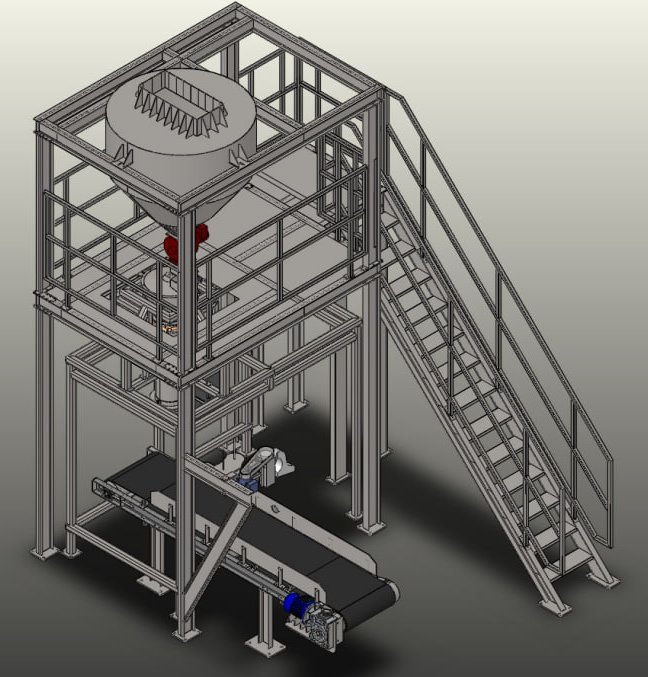

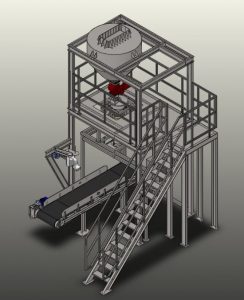

Installation of FAS-OM2 faces large bulk materials (both dry and high humidity in open plastic or paper bags.

The installation is designed for packing not very abrasive bulk materials – fertilizers, feed, sawdust and similar materials. For packing crushed stone, gravel and other rigid materialsWatch FASOM1

After packing, the bags are automatically seized and / or stitched.

The principle of work

- The source material is loaded into the receiving hopper.

- The weight of the bag is set on the control panel.

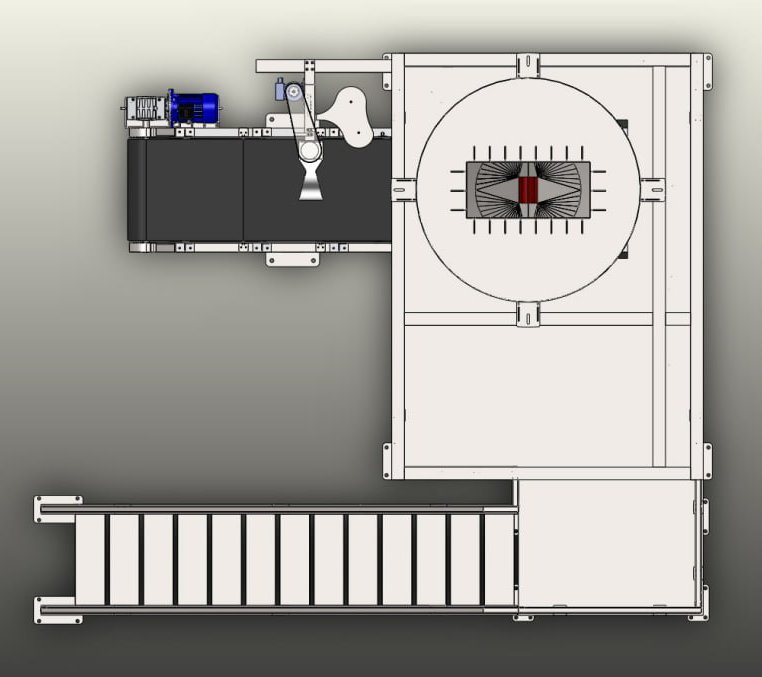

- The installation doses the material into an intermediate container, the dosage is in parallel, that is, while the bag is filled with a new dosage cycle, this increases productivity by 2 times. Dosage is made by a rotary feeder.

- The bag is quickly filled from an intermediate container.

- The bag is transmitted to automatic seal and \ or suturing.

- A new bag is placed and the Start button is pressed.

Competitive advantages

- Parallel work – while the weight dosage is underway at the same time, packaging is performed. An increase in performance by half.

- Long -term work due to the use of the strip conveyor.

- The accuracy of the dosage due to the use of high -quality tensodists.

- Simplicity of management.

- Only one operator needs. Reducing salary costs by double.

See news with photos and videos from production – shipping packing at the console factory.

Price and how to buy

The cost of installing FASOM2 for packing sand, crushed stone, expanded clay canLook at the price list.

- Calculation of the installation cost of ordinary steel.

- Calculation of the installation cost of stainless steel.

Video work

Drawings

See also

- See news with photos and videos from production – shipping packing at the console factory.

- Equipment for packing crushed stone, gravel, expanded clay in FAS-OM1 bags