Installation of FASOM1 faces large bulk materials in open bags.

Installation of FASOM1 faces large bulk materials in open bags.

Bags can be:

- paper – then they are automatically sewn up

- polyethylene – then they are automatically sealed and can further automatically flash

This installation faces large materials – such as crushed stone, gravel, expanded clay, etc.

If you need packing a lighter and more small mixture, such as sawdust, fertilizers, feed, etc., then we recommend that you look at the FAS-OM2 model.

If preliminary washing of crushed stone is required, then you can useInstallation of the crushed stone sip lmsh-1.

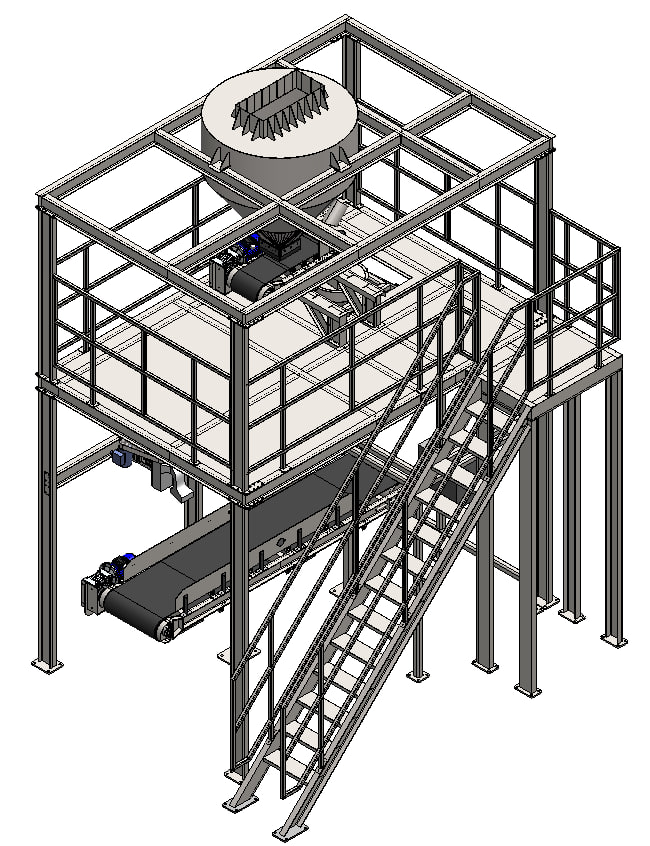

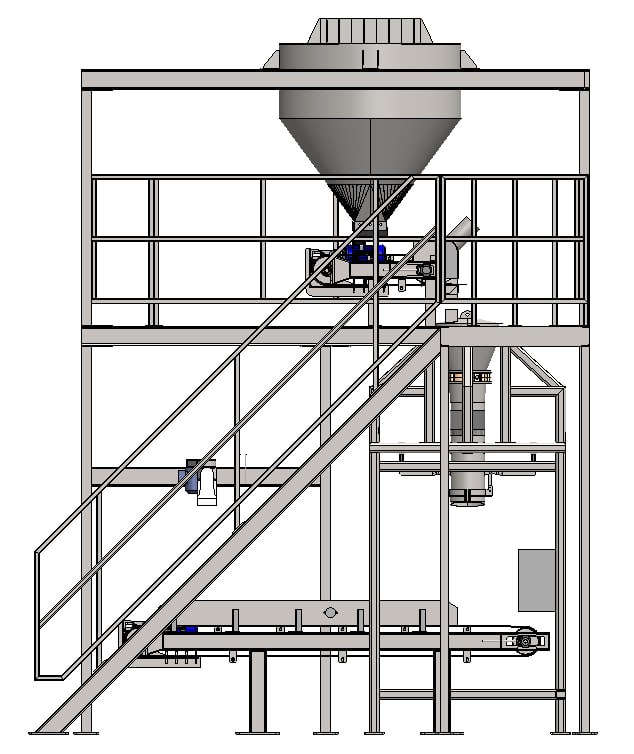

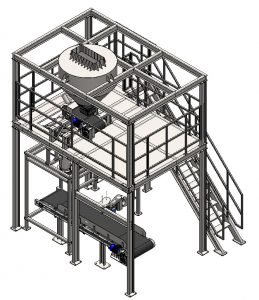

The uniqueness of this equipment lies in the fact that the material (crushed stone, gravel, sand) is fed to the package by not a screw conveyor, but a strip conveyor. Thanks to this, uninterrupted and long -term installation operation is ensured. As you know, when transferring sand (crushed stone, gravel, expanded clay), he quickly wear out with a screw transporter and fails. Thanks to the use of the strip conveyor, this problem is solved.

Packing of bulk materials can be carried out both polyethylene (polypropylene) and into paper bags. The total weight of the bags is set on the control panel and can vary from 5 to 50 kg. It is also possible to make to order installations for packing with other weight ranges.

- The news of the shipment September 2022.

- The news of the shipment September 2016.

- The news about the shipment of installation in Novokuznetsk with a photo (February 2015).

The principle of work

- The source material is loaded into the receiving hopper.

- The weight of the bag is set on the control panel.

- The installation doses the material into an intermediate container, the dosage is in parallel, that is, while the bag is filled with a new dosage cycle, this increases productivity by 2 times.

- The bag is quickly filled from an intermediate container.

- The bag is transmitted to automatic seal and \ or suturing.

- A new bag is placed and the Start button is pressed.

Competitive advantages

- Parallel work – while weighing dashing is underway at the same time

- Long -term work due to the use of the strip conveyor.

- The accuracy of the dosage due to the use of high -quality tensodists.

- Simplicity of management.

The installation of FASOM1 can always be seen in the work in the existing production.

Technical characteristics

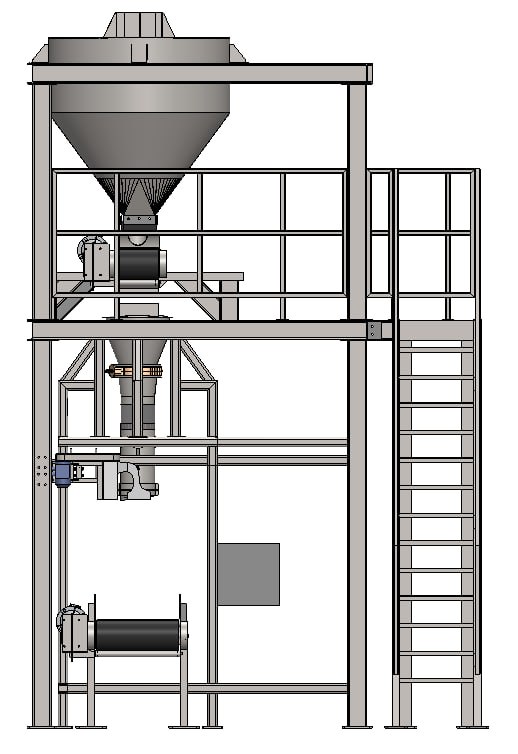

- Height 2800mm, width 1800mm, length 3200mm.

- Weight – 2100 kg.

- Power voltage – 380V

- Power consumption – 3.2 kW

Price and how to buy

The cost of installing FASOM1 canLook at the price list.

- Calculation of the installation cost of ordinary steel.

- Calculation of the installation cost of stainless steel.

Video work

Drawings