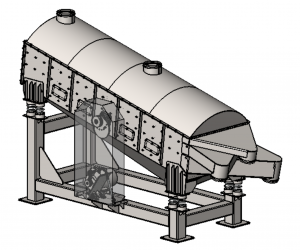

The rumble of vibration aamix is carried out according to time -tested structures on modern equipment.

The rumble of vibration aamix is carried out according to time -tested structures on modern equipment.

At the moment, our plant produces three standard variants of vibrational roar, as well as the production of any models to order.

All typical models allow you to sift sand, gravel and crushed stone with a fraction of up to 10mm. Also, custom -made models can sift other materials, for example – glass, nuts, cereals and much more. It is possible to produce in contact with the products of a part of stainless metal for the food industry.

See the news of the shipment with photos.

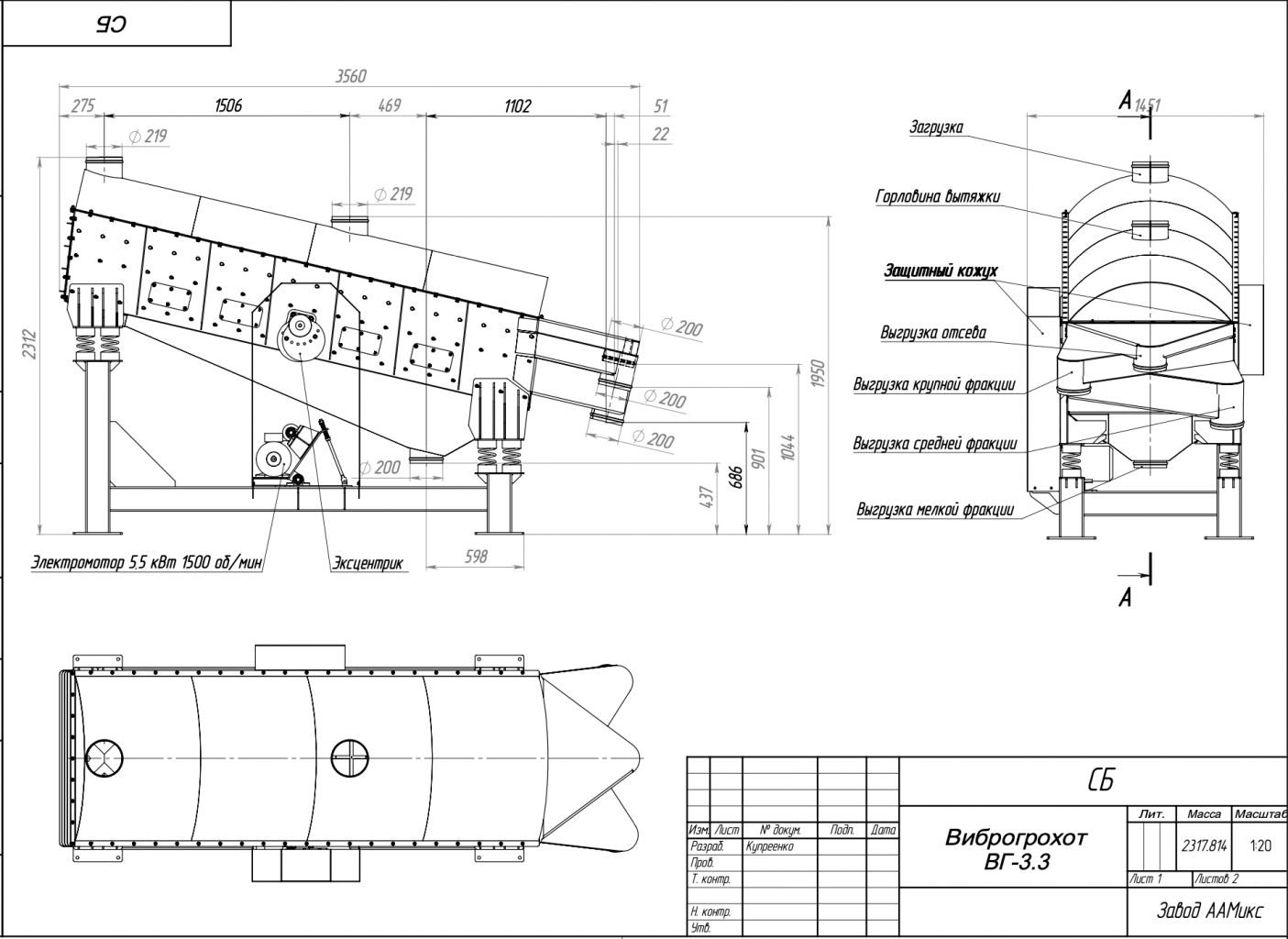

Download a drawing with dimensions.

Description and advantages

We have been producing and delivering vibrational roars for more than 15 years in Russia and the world and during this time easy to maintain and reliable design has been worked out.

- The structural elements are made of a square pipe, which gives the design stiffness and durability

- The use of imbalance instead of standard vibrators allows you to get high amplitude vibration and greater performance

- the grids are removable and are easily replaced with wear

- Material outputs are convenient for its further submission to the right places

See the prices for typical vibration roofs.

Technical characteristics

Download a drawing with dimensions.

| Model | Aamix VG-1 |

Aamix VG-2 |

Aamix VG-3 |

| The length of the grid, mm | 1200 | 1800 | 2900 |

| Engine power, kW | 2.2 | 3 | 3 |

| Weight, kg | 280 | 520 | 840 |

| The average performance (depending on the humidity of the material, stickiness, etc.), cubic meter. per hour | 5 | 10 | 20 |

| The number of fractions for Zasov (to order on any rumble can be set up arbitrarily the number of sieves) | 1 | 2 | 3 |

| Dimensions, DHSHD, mm | 1900x1220x1850 | 2500x1420x1850 | 3600x1420x1950 |

Complete

1. Different nets

We produce three typical models that differ in different power and length of the sifting surface. Each model can be equipped with one, two or three sifting nets.

That is, on any model of the roar, you can sift up to 3 fractions of the material.

Also, nets can be made of ordinary steel or stainless.

2. Material of the tray

The tray in which the nets stand and the nets themselves can be made of stainless steel. This is often required when working with food or chemically aggressive materials.

3. Covered roar

The roar can be completely covered with a lid. This is often required when working in rooms. Then sifting products fall into it through the neck and go through the neck in a container for the sifted material. This excludes dusting.

4. Special nets for small or sticky materials

4. Special nets for small or sticky materials

When the material is very small or sticky, it clogs nets. To fight this, we make a double grid. The lower part is a sheet with large holes. And the upper small mesh. Great rubber balls are placed between them. With vibration, they jump and beat off the material from a small grid, which excludes its clogging.

Download a drawing with dimensions.

You can see the prices of all options in the price list.

Send a request for vibration roar online

Certificate

We certify all our equipment for the confidence of our customers as and for sending foreign customers.

Photo from shipments

Video

In the video below, the vibrationhole works in the drying line of the sand scattering it into 2 fractions, for subsequent shipment in the Big Bigs.

Video of test run

More equipment for working with sand and gravel

- Drummer roar.

- Circular Vibrosito.

- Bunkers of storage of sand and crushed stone.

- Packing line of sand in bags.

- Drum drying of sand.