In 2017, the Aamix plant performed a unique development for the Bograd Mining and Processing Plant.

The client needed a drum for drying sand, with a capacity of 20 tons per hour.

The uniqueness of the request was that the Bogradsky GOK (enterprise in Abakan) did not have the opportunity to use gas as fuel, but there was a lot of cheap and good coal. Therefore, the request was for the production of a drum with a coal burner.

More

Task parameters:

Task parameters:

- Sand drying performance – up to 20 tons per hour

- Coal is a standard, which is used in boiler rooms

- you need automatic coal feed and automatic ash issuing

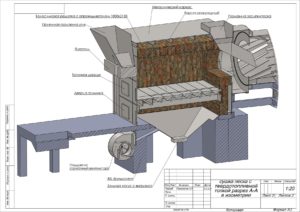

When studying the issue, the designers of our plant studied different types of burners, such as American and Chinese, which work on crushed coal. The main obstacles to their use were that they required grinding of coal into dust, it is very moody to working conditions and during their work there is dust that can settle on the sand, a little (predict how much you can put the experiments) changing its composition.

Therefore, we settled on standard and reliable fireboxes that are produced in Russia.

However, there was also an obstacle in the fact that these furnaces are intended for water boilers and manufacturers, although they make high -quality and reliable furnaces, while quite difficult to communicate and modernize, do not give full drawings, etc. Therefore, our designers flew to the Chelyabinsk region, to the manufacturer, studied the furnaces and their work on the spot, and then created a drying drum on the basis of these furnaces, which works with a standard and reliable firebox.

Drum characteristics:

- performance 20 tons per hour

- works on ordinary coal

- Automatic coal feed

- Automatic ash

More information:

- Full description of the drums of drying sand

- Prices for standard drums

- Full catalog of our products

- Drying projects

Photo from the plant, solemn launch

Photo shipping from our plant in Old Russ

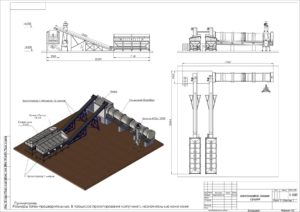

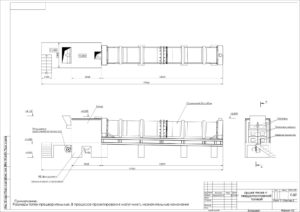

The project of the drying line of sand on coal