A client from Khabarovsk approached us with a request to make a plant that will produce 20 tons per hour of prepackaged mixes.

The composition of the mixtures is quite complex, includes a lightweight filler – perlite.

At the time of the request, the client had a paper project of steel structures (in pdf files) made by a third-party company.

After the contract was awarded, we carried out the work

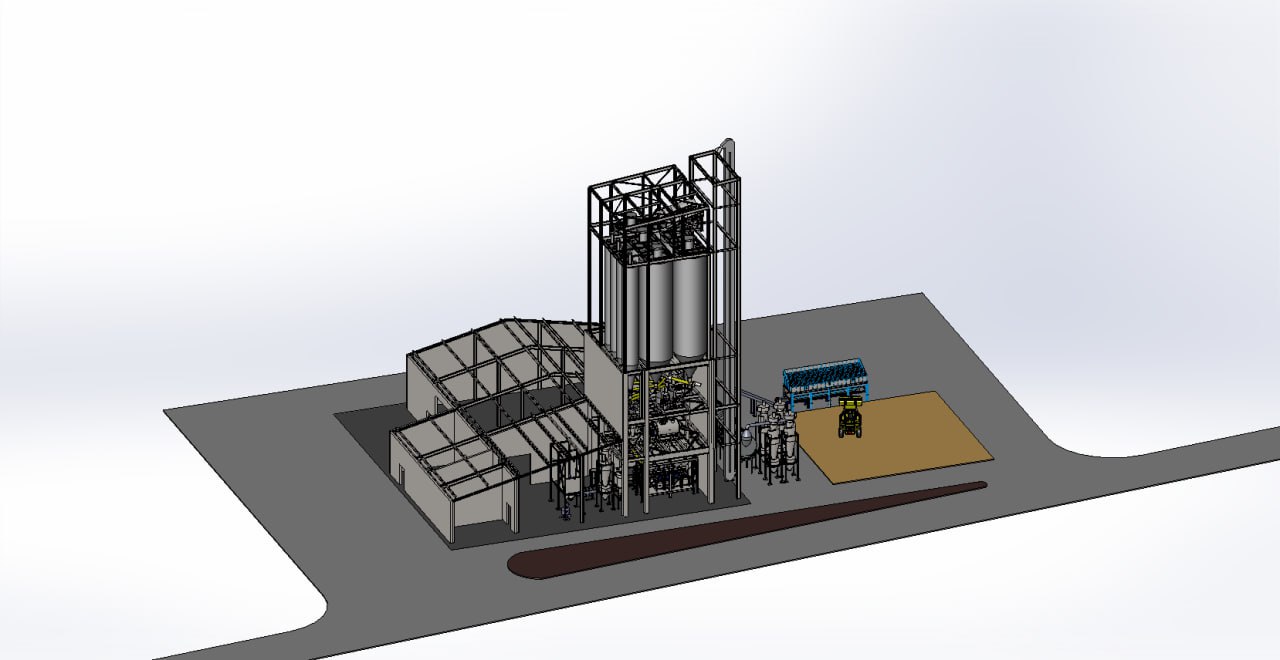

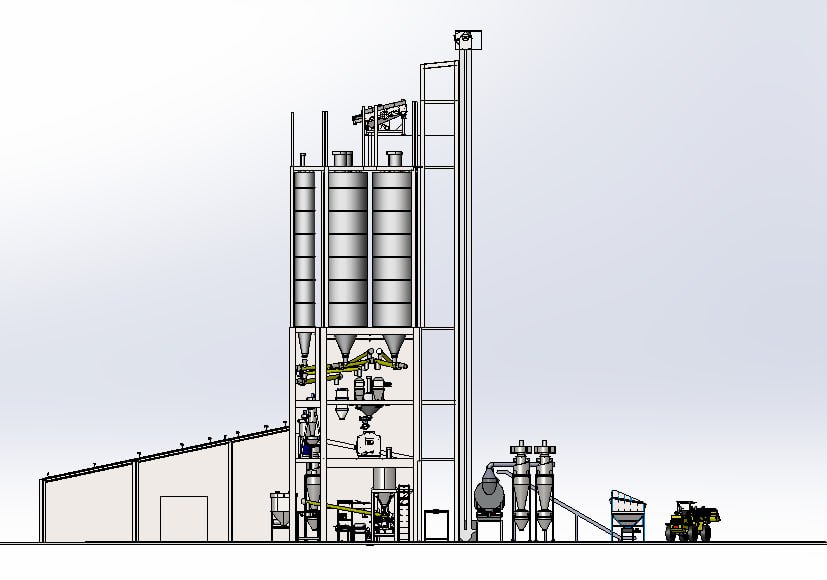

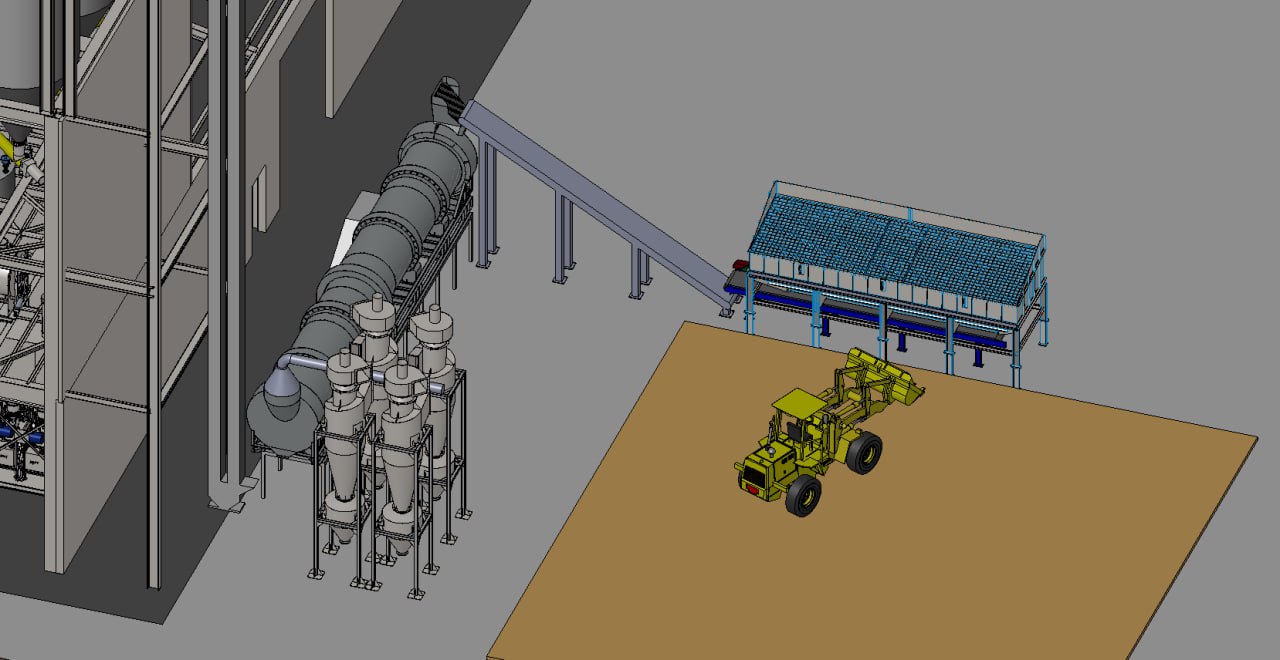

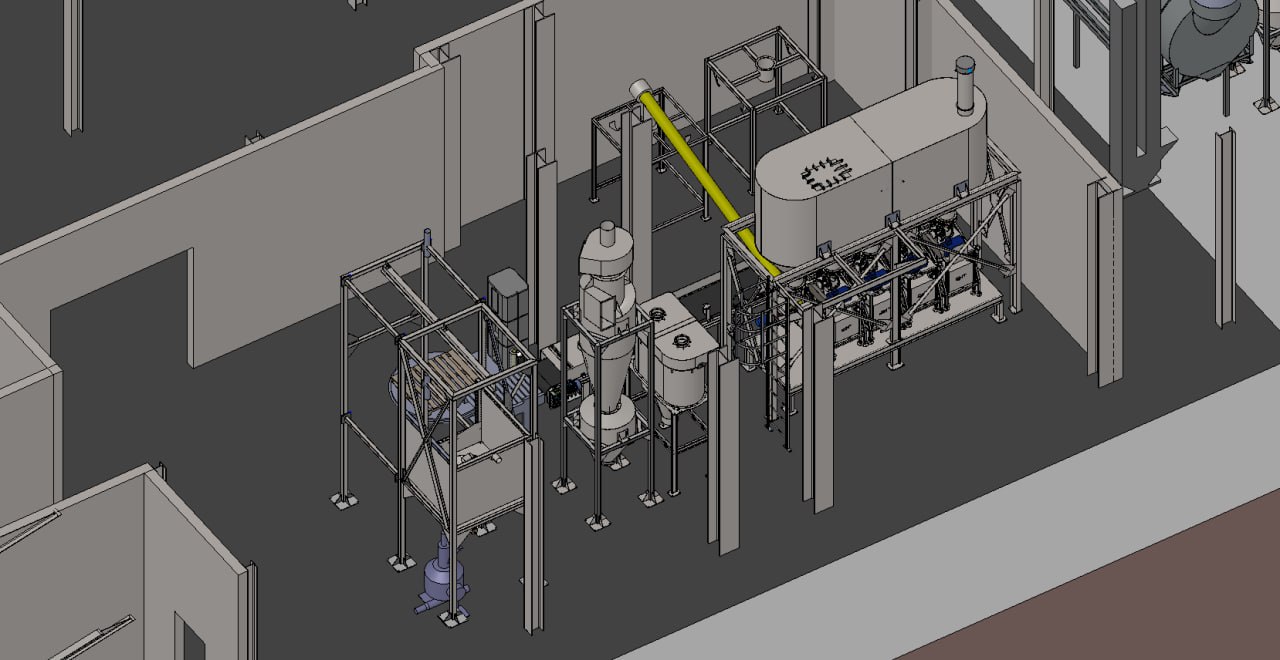

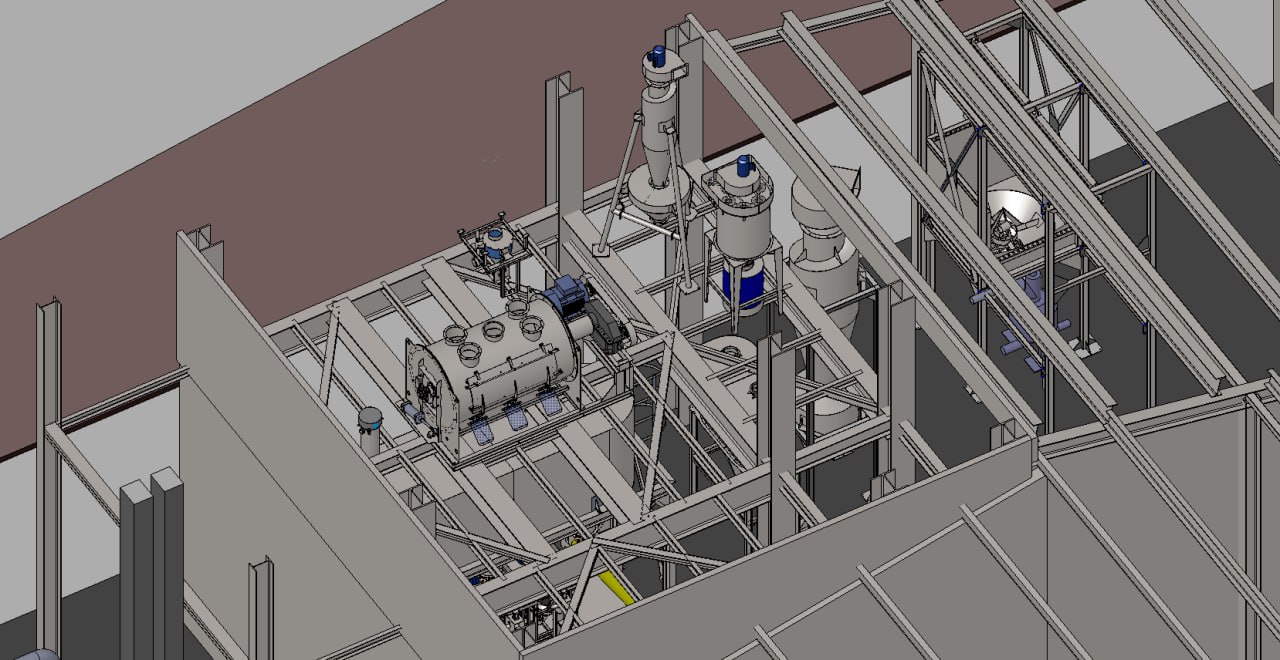

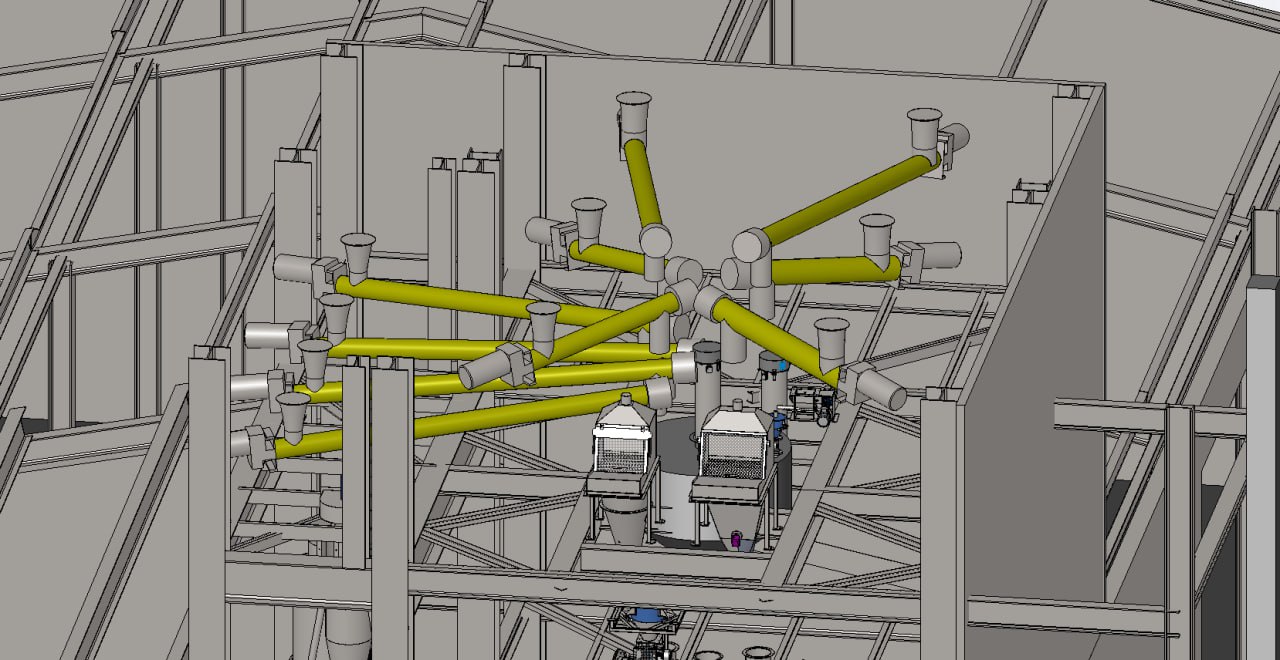

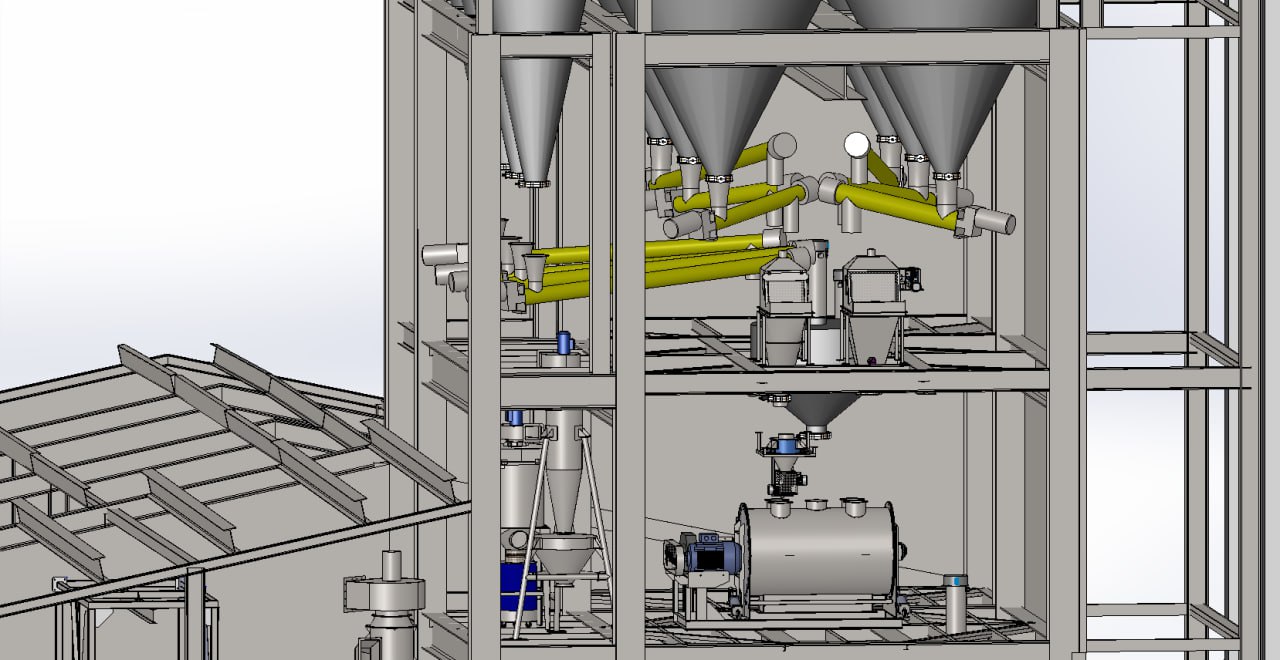

- Made an interactive 3d model of the plant and placed the equipment in it.

- Made a full specification of the equipment.

Further, there were questions to the initial design of the steel structures, as it was made with errors (no service areas, replenishment, etc.). The project was sent for revision.

As a result, we fully designed the plant and provided the documents

- ECSR

- TCU

- Specification.

- Development diary (refinements and revisions).

- Plant Images.

The design of 20 tons per hour dry mix line includes

- Sand preparation and drying line 20 tons per hour.

- Bulk dispenser of perlite (lightweight filler).

- Complete plant control from a single center.

- Automatic additive dosing.

- Four bagging.

- A robot of putting bags on the filling machines.

See also.