The mixers for the production of dry building mixtures WBH manufactured by WAM, Italy are of high quality, durability, ease of work and complete mixing of components.

Download description of the mixer mixer

Go to the page with a list of mixers mixers.

Throughout the world, more than 1000 mixers of this type were delivered and they have established themselves in the best way.

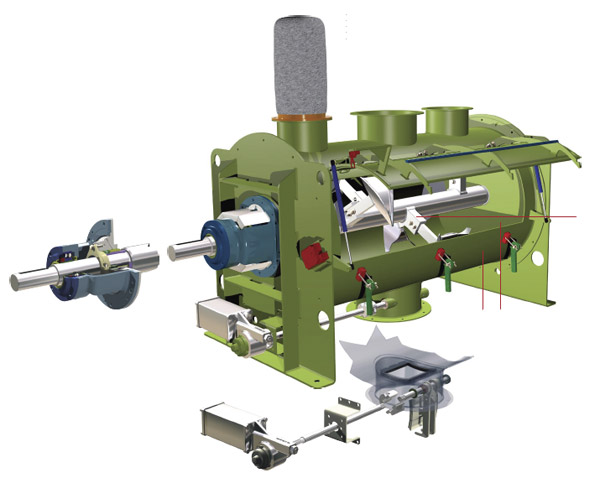

Minter of dry mixturesWBH is a mixing chamber complete with a loading neck, an unloading neck with a shutter and exhaust opening, a mixing rotor, two plates that cover the ends of the chamber for placing the end bearings complete with a set of adjustable gaskets for the shaft, and a drive with power transmission.

Flowering devices in the form of a lime or an inclined blade rotate at a special angle with respect to the central shaft inside the horizontal cylindrical chamber. This avoids the appearance of dead zones and movement at slow speed, which provides high accuracy of mixing. In some cases, additional mixers with a high mixing speed are installed to achieve the desired effect.

The principle of action

WBH mixers function according to the principle of liquid layers formed mechanically. A special shape, location and speed of rotation of mixing devices create a centrifugal vortex -shaped movement, which allows you to project materials in a three -dimensional angle and mix them with each other. This is a guarantee that components with various granulometric indicators and density are mixed accurately, efficiently and in a very short time.

WBH dry mixers are used to mix with each other powders, grains and short -wave materials, to moisturize, agglomeration and granulation, as well as for mixing few astringent liquids or pastes.

Competitive advantages

- Strong mixing chamber made of carbon, wear-resistant or stainless steel AISI 304-304L-316-316L

- Brief mixing time (1-4 min)

- The maximum uniformity of the mixture

- Excellent reproduction of portions

- Minimum wear small requirements for technical support

- Simplicity in the regulation and replacement of mixing devices

- Ease of cleaning and access to all the internal details of the machine

Technical characteristics

- Capacity: from 75 to 15,000 liters

- Drives: from 4.0 kW to 200 kW

- Mixing opportunities: from 2 to 15 servings per hour (depending on the recipe for the mixture and configuration of the machine)

- The end bearings complete with a set of sealing pads for the shaft with the possibility of choosing between aeration of water or nitrogen

- The unloading neck adjacent to the camera

Additional options

- Steel for difficult working conditions, stainless steel, special structural materials

- The possibility of wear -resistant coating

- Bearings of the bags with a lining ring and aeration or with a lubricant

- Liquid supply system

- Decompression shield

- Sampling system

- Temperature probes RT 100 with a heat exchange system

- A wide range of mixing devices (boxed, gear, with blades, with gear blades), also in the option with a wear -resistant coating

It is also possible to supply a completely similar mixer of dry mixtures of Prof-SC, Russian production.Download prices for mixers of dry mixtures

These mixers are used infactories for the production of dry building mixturesOr in separate tasks to mix dry materials.