Our regular customer, the company of Glavstroy, faced the task of modernizing part of its BSU for the production of a masonry solution. To fulfill this task, we worked with the engineers and technologists of the company embedding the sifting unit of raw sand. This will allow the existing standard BSU to produce a high -quality pantry.

Our regular customer, the company of Glavstroy, faced the task of modernizing part of its BSU for the production of a masonry solution. To fulfill this task, we worked with the engineers and technologists of the company embedding the sifting unit of raw sand. This will allow the existing standard BSU to produce a high -quality pantry.

Setting the problem

More

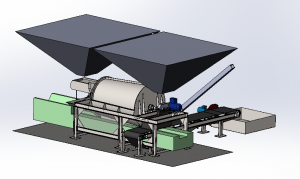

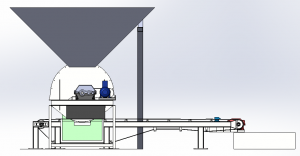

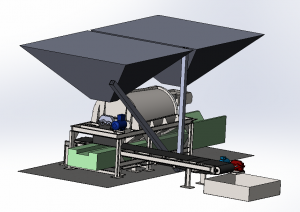

- There is a standard BSU in which bulk components are served from bunkers (black on model), to a single weight conveyor (green in the diagram)

- An ungounded sand from a career comes to one of the bunkers

- For the production of the pantry mixture, the fraction must be no more than 3 mm

- It is necessary to modernize the BSU so that it produces masonry solutions

Solution

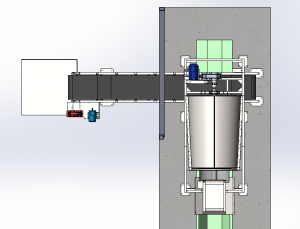

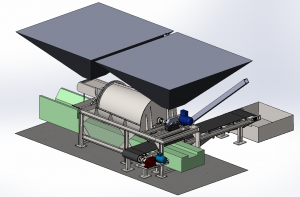

- Between the bunker, in which the sand is stored and we put a weight transporterDrum of rumble AAMIX BG-2which allows you to sift wet sand and is highly performance, very high reliability and quiet work

- For the output of the wems, we made a tape conveyor of complex shape

- All drawings and models are made in contact with engineers and technologists of the Glavstroy

Production began in November 2020, follow the news here and inOur InstagramWhere we publish real photos from production.

About the company Glavstroy

The company “Glavstroy St. Petersburg” (LLC “Glavstroy-SPB Specialized Developer”) is one of the largest Russian developers implementing projects of integrated development of urban territories with the construction of social, commercial and road infrastructure.

A map of the factories and iconic projects we have done

This project is added to the map of our customers.