We have been participating in the Baltimix conference on an ongoing basis since 2018.

Last year we did a report on factory automation – news from 2023.

Over the course of this year, we have moved even further in the direction of automation.

Robotic bagging robot

In dry mix production, one of the most difficult areas for workers is the bagging station.

In dry mix production, one of the most difficult areas for workers is the bagging station.

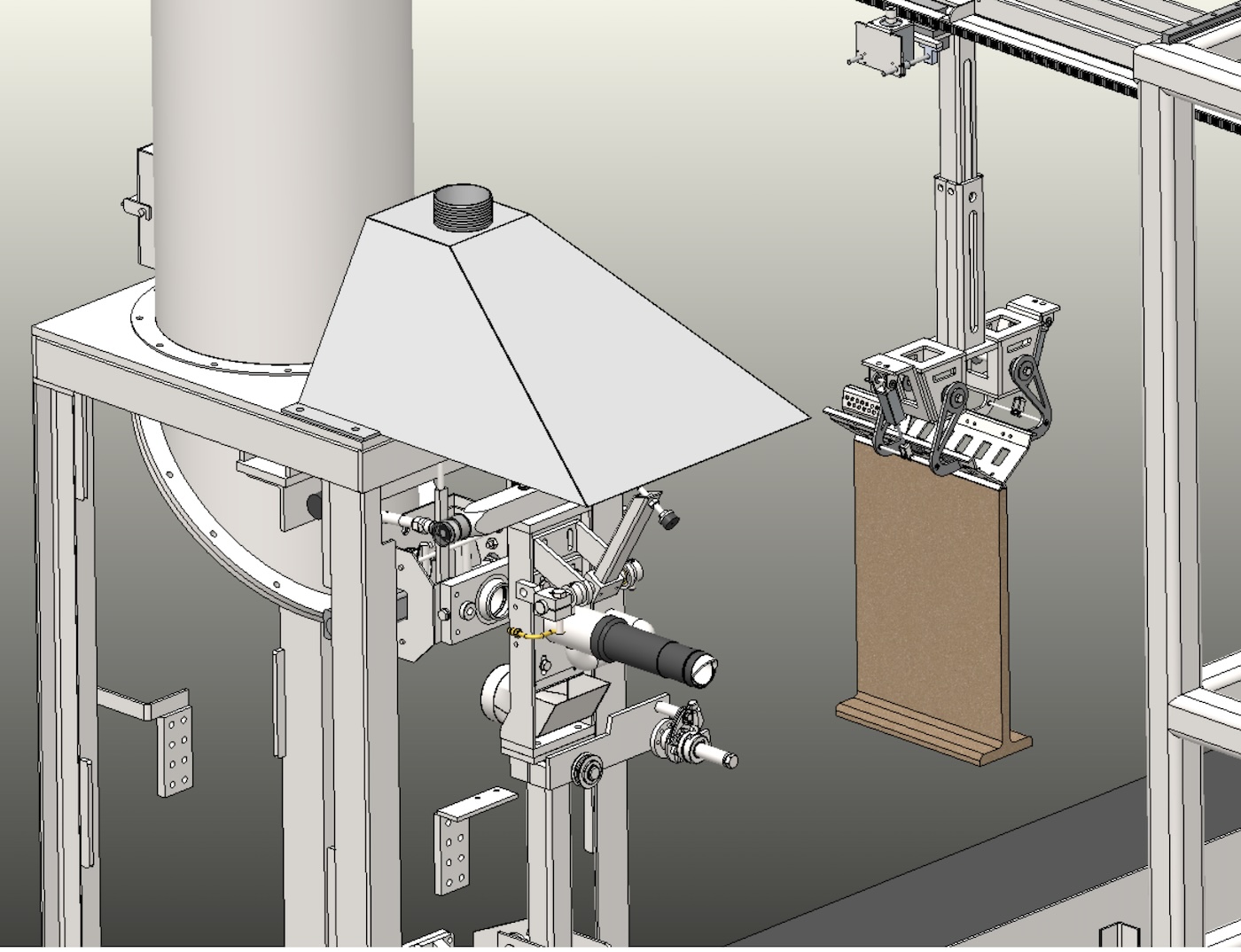

We have been developing filling stations for a long time, at this point they already look like a spaceship and they were already fully automatic in terms of weight gain and bag drop. Only the last step to fully automate this unit remained.

Bagging robots have been known for a long time and are produced by a number of companies. Since last year, the AAMix plant has also started to produce bagging robots for filling machines.

It is important to note that we fully produce this robot in our full-cycle production facility. The control program was created by our IT department, the program itself runs on an AATech industrial controller (IT division of our plant).

This guarantees the customer a complete service – fast delivery of spare parts, quality adjustment, full integration into existing accounting systems.

The composition of the bag putting robot: directly frame arm, empty bag feeding conveyor, ready bags feeding conveyor, trough auger conveyor for collecting slurry, inclined auger conveyor for slurry, big bag rack, bag dedusting aspiration unit.

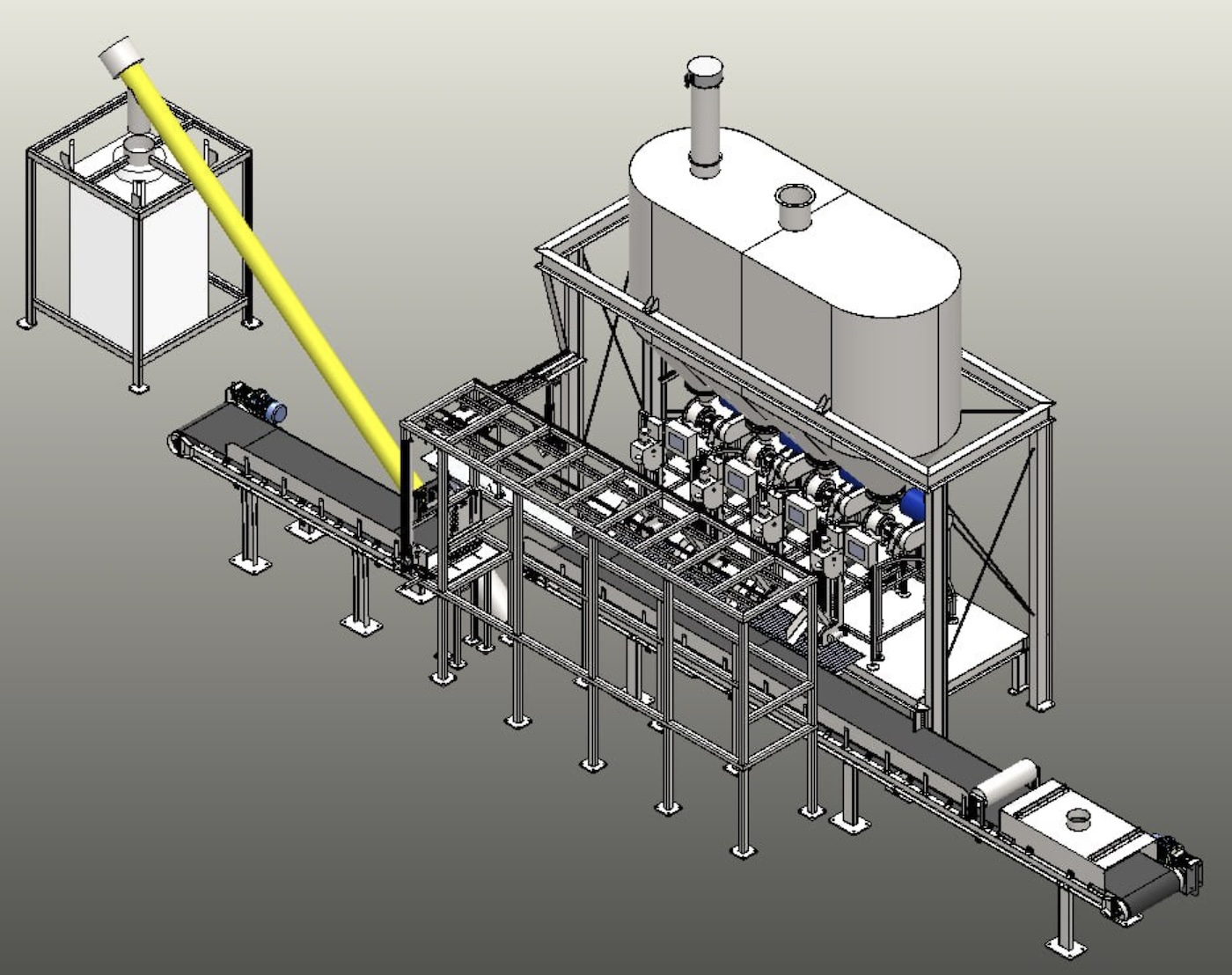

With the advent of automatic bagging, we are closer to fully automating plants.

Sand and cement are delivered by truck or wagon, then the drying of sand, feeding of bulk materials into the line is automatic.

Additives are automatically dosed from our bag spacers using microdosing screws. We would like to point out – a unique product.

The mixer is fully automatic.

The filling machine works in automatic mode, the bags are put on automatically.

Stacking of bags on pallets is done by hand by the robot.

Localization of all components is about 90%, most of the equipment is produced directly by AAMix.

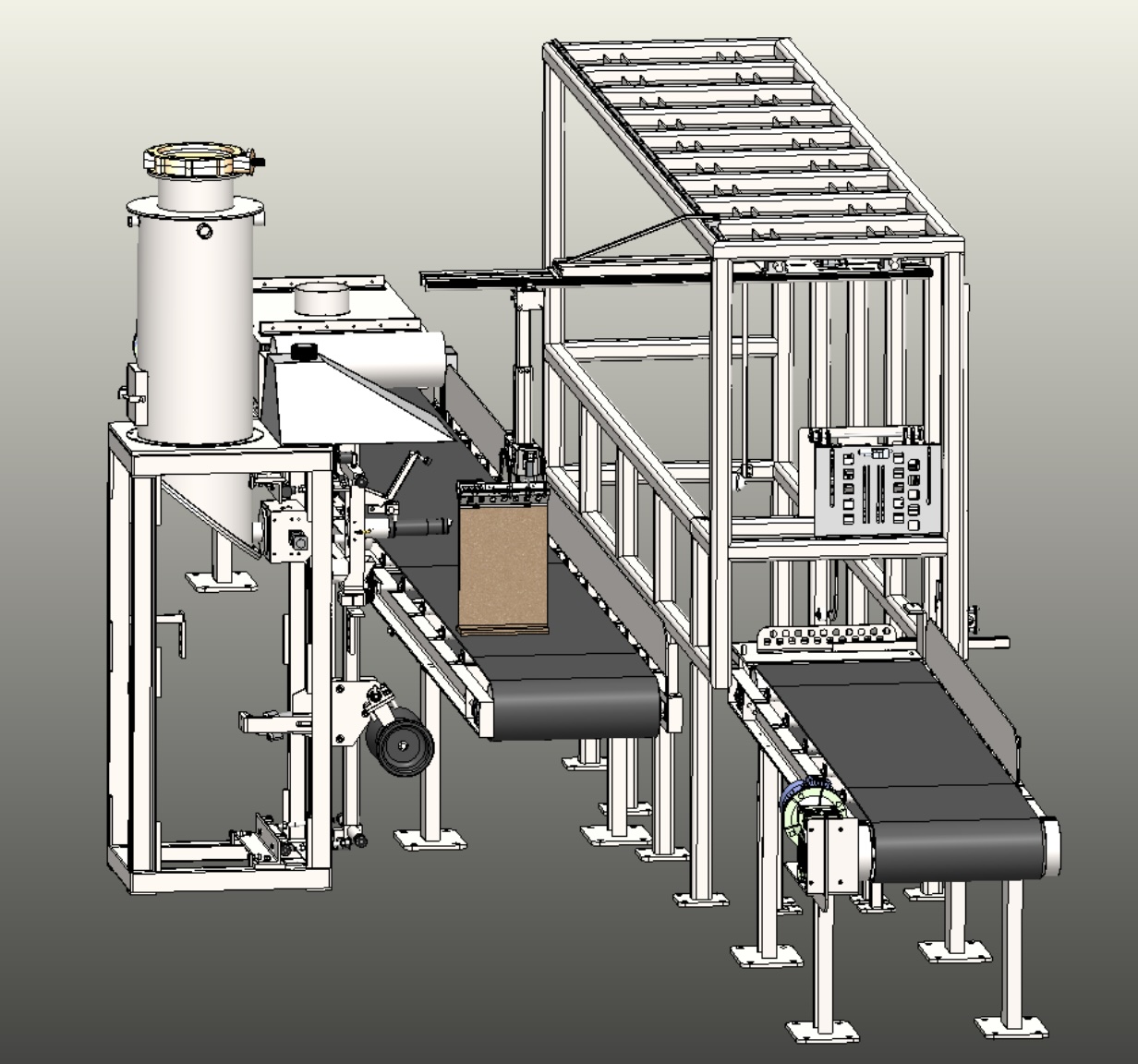

Modernization of the filling section of existing production facilities

For owners of existing plants, we develop a project to replace the old type of bagging area with a fully automatic one. This replacement provides a rare combination of increased productivity + reduced costs.

Let’s review point by point.

Old site with manual bagging:

- Employee Salary.

- Continuous rotation of employees.

- Because the conditions are harsh, downtime is common.

- As a consequence, the productivity of the site can drop dramatically.

- Difficulty in finding employees.

New site with automatic bagging:

- Can work multiple shifts, need one worker who maintains the bag putting robots and bag stacker.

- Easily adjust plant capacity without relying on hiring workers for the filling area.

- The productivity of the plant is close to its maximum.

- Ready accounting system and data transfer to MES, ERP system of the enterprise.

How modernization happens:

- To modernize the site, our experienced specialists will come in, take all measurements, and 3d scans of the site, discuss how and what will work with the customer’s technologists.

- We will make a complete 3d project, coordinate it.

- Then we’ll produce the equipment.

- Then we will carry out the supervision and production of the first batches.

The video shows 3d scans of the frame and dry mixer.

Economic effect

Workers production with manual bagging:

-

2 workers per shift, 2 shifts, approximately 10 workers (with substitutes).

Workers production with manual bagging:

- 1 worker per shift, 2 shifts, approximately 4 workers.

Total difference of 6 employees:

- Six employees, salary of 80 000 rubles, including taxes 480000 rubles

- If the company pays VAT, it will also be paid from the employees’ salaries, totaling 576,000 rubles monthly.

- Per year – 6.9 million rubles.

This is only the direct effect, which does not include losses from manual line downtime, resources spent on personnel management, etc.

Production effect

- We need to manage fewer people.

- Simplifying labor cost accounting.

- More stable production.

- The ability to scale up quickly – lowering Ð increasing productivity without incurring additional costs. That is, you don’t have to pay salaries to extra people or fire them, which also puts a strain on the company.

- Freeing up the resources of the company’s employees for development rather than wasting them on routine work.

How to buy a robot or order an upgrade

For ordering and cost calculation write info@isilos.ru, Telegram https://t.me/aamixru or call tel.: +7 (812) 408-41-82.

See also.