The Stroy-Baton plant has been operating in the equipment market for storing and processing bulk materials for more than 10 years. The company is engaged in the development, production and supply of products not only to different regions of Russia, but also to other countries. Products offered in a wide range are used in various fields of activity.

Production

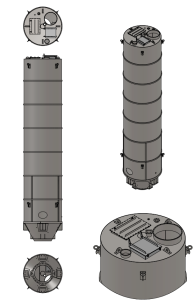

The Stroy-Baton plant independently develops and produces silage for storing flour. The equipment is made of stainless steel and STZ in different volumes (from 8 to 120 cubic meters). The use of innovative technologies and developments, modern equipment and high -quality materials ensures reliability, durability, simplicity and ease of operation of products.

The Stroy-Baton plant independently develops and produces silage for storing flour. The equipment is made of stainless steel and STZ in different volumes (from 8 to 120 cubic meters). The use of innovative technologies and developments, modern equipment and high -quality materials ensures reliability, durability, simplicity and ease of operation of products.

- Download price list with prices for equipment and components

- Download the description of flour silos in pdf >>

- Our products are certified! View certificate

Features of flour silos

- Even when using vibrodnis and modern aeration systems, it is possible to stick flour in a cone, so the structures are equipped with a unique configuration service.

- Each silos is mandatory equipped with explosion -protective panels.

Competitive advantages

- Equipment details are welded on both sides (from the inside and outside).

- By order, a special coating of the inside of the equipment is performed.

- We can make silage for special working conditions on an individual order.

Complete

The cost of the storage of the flour indicated in the price list involves the standard configuration:

- silage

- Explosion protection panel

- Cleaning filter of incoming flour

- supporting structures

- observation hatch

- ladder

- Upper service site

To ensure uninterrupted and efficient work at the request of the client, silos for storing flour can be equipped with additional equipment. Being an official dealer of WAM, we carry out additional equipment as soon as possible at the prices of the manufacturer.

Recommended additional equipment

All additional equipment can be pre -installed on silage and delivered by our company. We are the official navigators of WAM and provide low prices.

- The safety reset valve prevents an excess or lack of pressure inside the container. (required to install!)Description >>

- Filter of output air. (is needed when downloading flour into silos)Description >>

- Two level sensors provide control over the filling of the device.Description >>

- The lower vibrosis for uniform distribution of flour and improve its feed.

- The lower valve, which allows you to stop the flour, if it is necessary to maintain a screw conveyor (usually a throttle shutter is installed with a diameter of 200 to 400 mm).Description >>

- Aeration system.Description >>

- Control panel (level alarm, filter control, etc.)

- To unload flour, as a rule, is usedSwitch conveyor.

Product weighing, unique development!

We have developed and successfully installed on several charms the system of weighing silos with flour. This allows you to control the flow of flour and its consumption. For this, Silos has special supports for the tensodists on which it is based. After that, you can install any power sensors (if we install, then we use Tenzo-M sensors) and receive weight information.

The cost of silos in the manufacture of the tensoport does not change, but this must be indicated when ordering, because Structurally, the silage differs from the standard.

Our clients

Our silos is installed on many food enterprises in Russia and, due to quality production and a well -thought -out design, serve without complaints.

- The largest order, the battery of silos for the Grozny Bakery

- Our regular customer, Russian Trapeza LLC – a large enterprise supplies factories for the production of bakery products in Russia

- and many others ..

We make silos for storing flour both a standard volume and for the needs of the client. The table contains typical models, the prices of which can be viewed inPrice list.

| Volume (cubic meter m) | Weight (tons) | Dimensions | |

| Height (m) | Diameter (m) | ||

| 8 | 2 | 5 | 2.4 |

| 20 | 3.75 | 8.5 | 2.4 |

| 40 | 5.5 | 13 | 2.4 |

| 60 | 8 | 13.2 | 2.9 |

| 120 | 12 | 15.7 | 3.8 |

To order equipment, write toinfo@isilos.ruOr call: (812) 331-99-46.