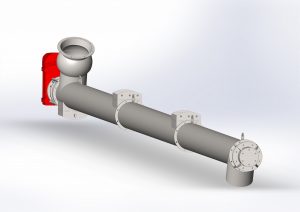

AAMIXFLOW SP AAMIXFLOW SP model is designed to transmit sand, chalk, microcalcite and other highly abrasive materials.

AAMIXFLOW SP AAMIXFLOW SP model is designed to transmit sand, chalk, microcalcite and other highly abrasive materials.

The screw is designed for difficult working conditions, taking into account the experience of the operation of imported screws on many plants of dry mixtures.

The screw is produced at the Aamix factory in St. Petersburg. This model works at many enterprises and factories, including industry leaders. Guarantee 1 year, all spare parts are in a warehouse in St. Petersburg.

The problem solved

- Even specialized conveyors of imported (including European) manufacturers very quickly fail with continuous work with sand, chalk, etc.

- The cost of imported transporters for these materials is close to 2 million.

- The terms for the supply of imported transporters are usually about 4-6 months.

AAMIXFLOW characteristics SP models

- All couplings and bearings are made from contact with the material, this greatly increases durability.

- The contraction of the screw and pipes is enhanced.

- Motors of the production of the Russian Federation, increased capacity.

- A full production cycle in St. Petersburg – low terms, availability of spare parts.

Models

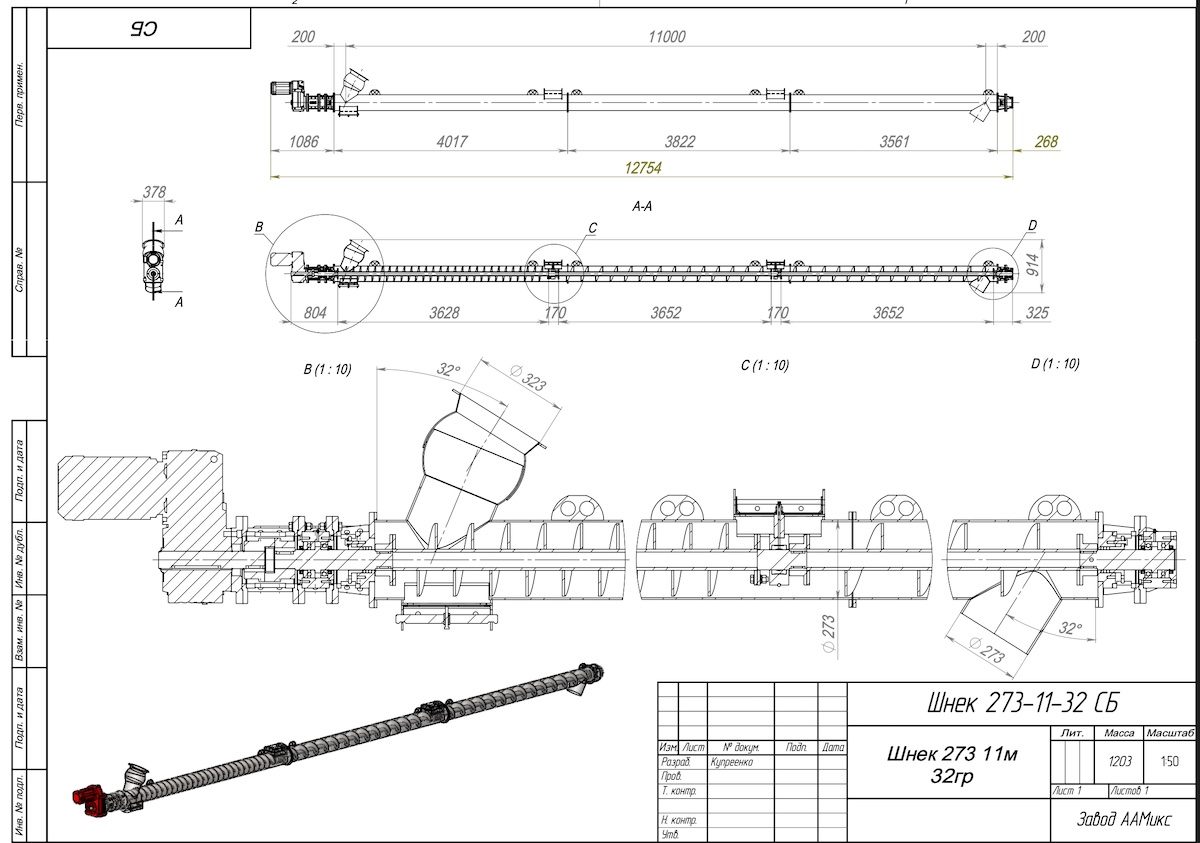

Below two typical models of the screws for example, we produce screws from 1 to 15 meters long.

- AAMIXFLOW N273SP model, diameter219mm, length 10 meters.

Productivity up to 48 cubic meters. per hour, tilt 45%, power 15 kW.

- AAMIXFLOW N273SP model, diameter273mm, length 10 meters.

Productivity up to 65 cubic meters. per hour, tilt 45%, power 18.5 kW.

- Any length to order.

See the prices for typical models in the price list.

Drawing

See also

- AMIXFLOW SHREECHER Microderia conveyor, diameter 108mm.

- AAMIX Flow M42 Microder for Brewing Products.