Fluckers of dry mixtures work in a highly abused environment in 2-3 shifts. Any simple mixer leads to large financial losses. Therefore, it is important to understand how reliable the mixer is and how quickly you can produce maintenance.

Fluckers of dry mixtures work in a highly abused environment in 2-3 shifts. Any simple mixer leads to large financial losses. Therefore, it is important to understand how reliable the mixer is and how quickly you can produce maintenance.

One of the important points is what drive is used from motor to the shaft of the mixer. Options are possible:

- Direct drive

- The drive through the coupling

The AAMIX plant in the design of the mixer does not use direct drive, since when directly connecting the drive to the shaft, the vibration from the mixer shaft is directly transmitted to the gearboxes, which leads to increased wear and as a result of the failure.On all mixers, directly the bearings of the mixer shaft, they have a lesser service life than the gearboxes of the gearbox. And with a direct connection of the drive with the initial wear of the bearings of the mixer shaft, increased wear of the gearbox bearings automatically begins.

When connecting through the coupling, we replace only the bearings of the mixer shaft (this work is carried out directly at the work without dismantling equipment). Replacing the gearbox bearings requires its complete dismantling and special equipment. As a rule, such work can only be done in a specialized locksmith workshop.

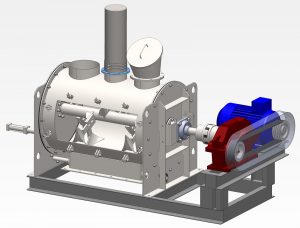

In the mixers of the production of the Aamix, the gearbox is connected through the coupling, which allows you to remove the vibration loads from the gearbox, respectively, the durability of the work increases.

The motor is connected to the gearbox using a belt transmission, this allows you to maintain the entire drive in service and distribute equal loads on the drive when jaming the mixer.

Direct -drive mixers are usually cheaper and are made faster.

But since the Aamix plant gives a guarantee for its equipment, and also performs post -warranty service, taking into account the above, we definitely do not recommend installing the mixer with direct drive.