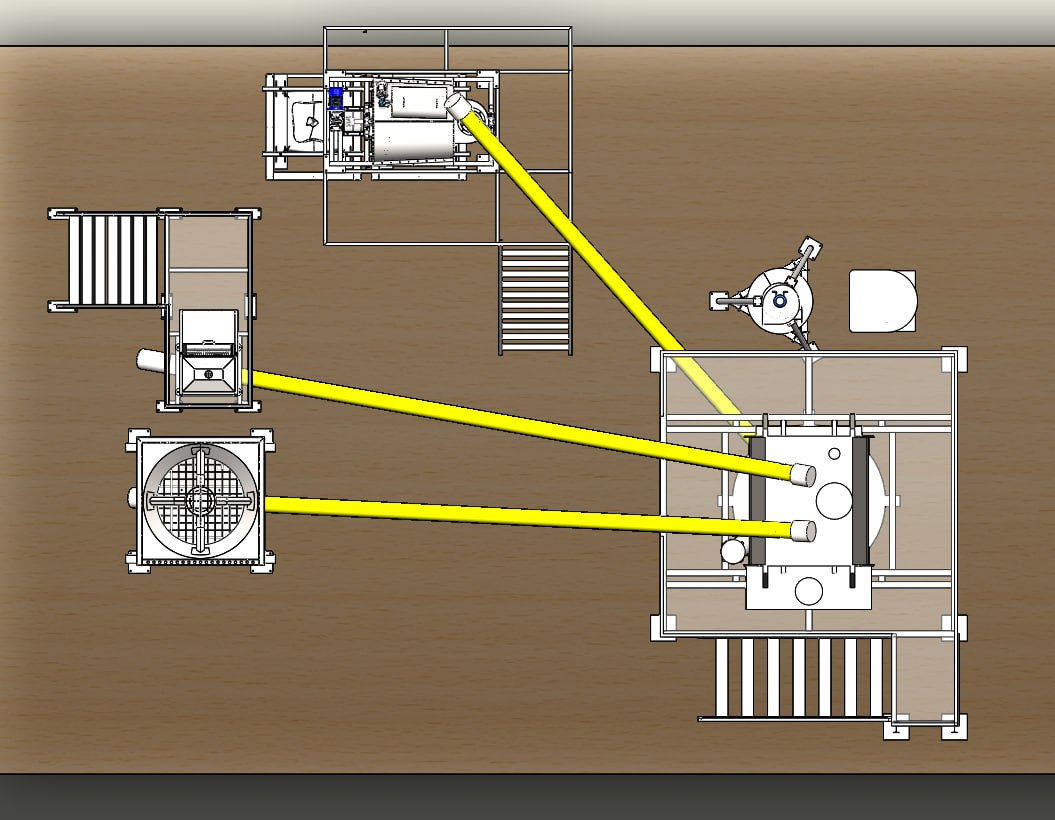

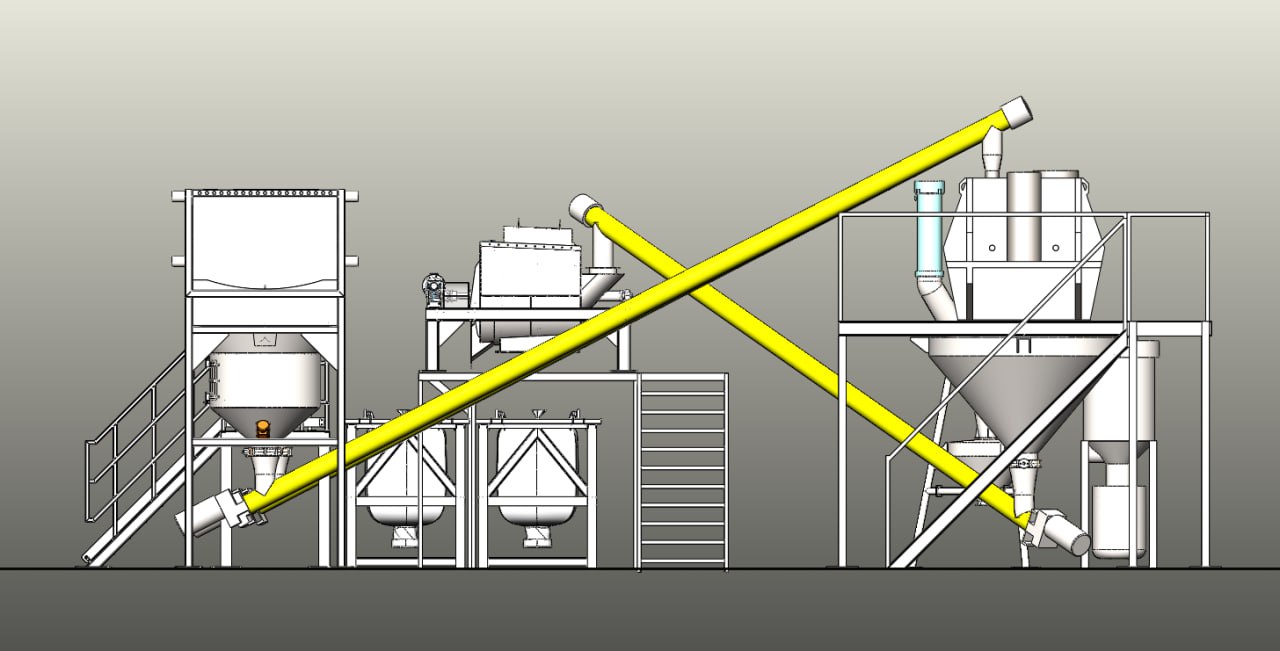

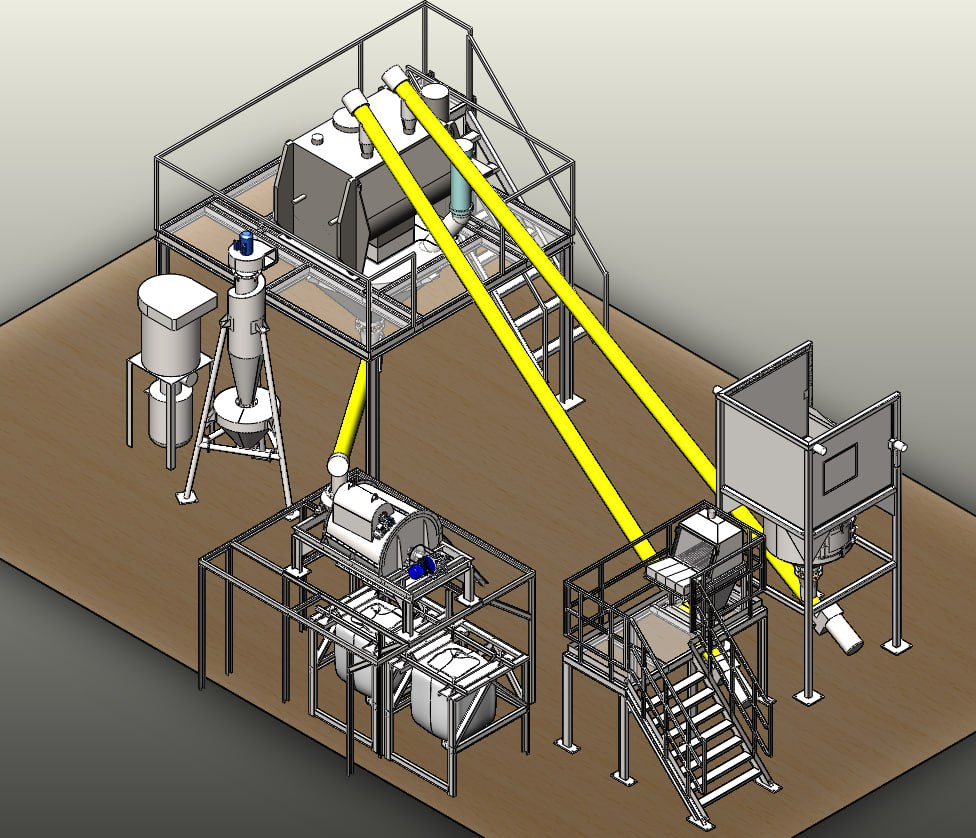

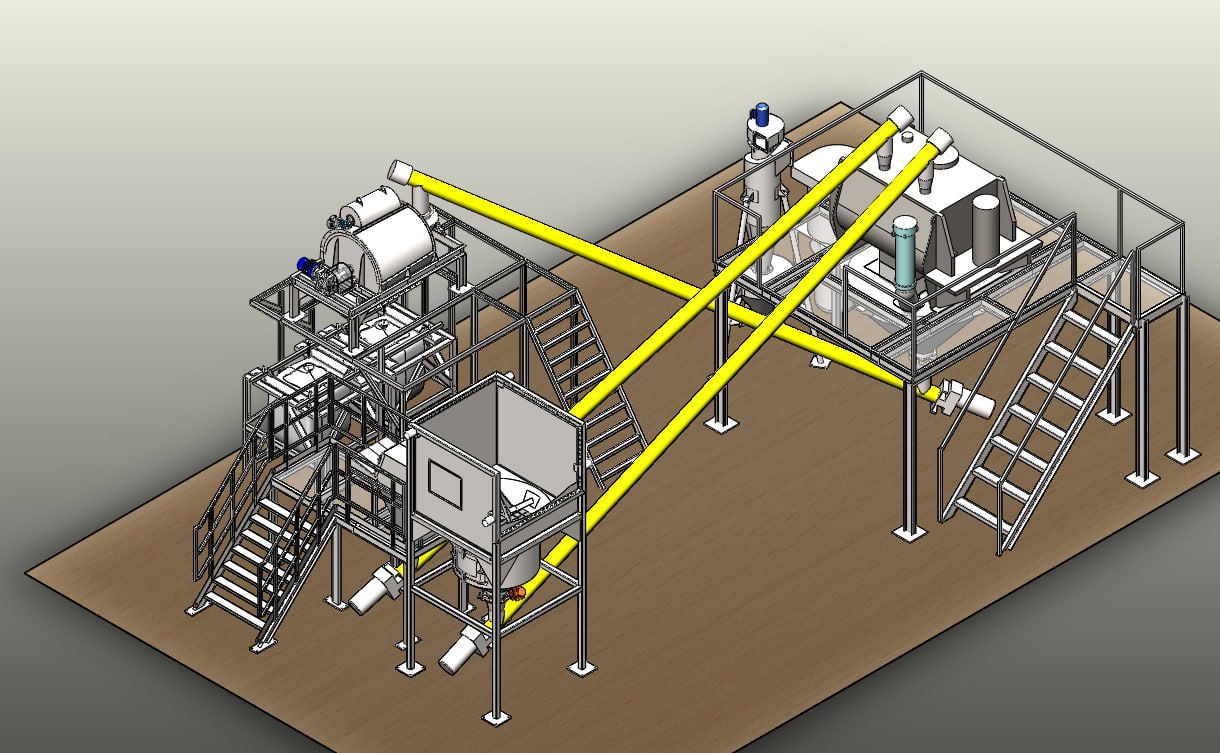

This line is designed for the production and packaging of washing powder and other detergents.

The line is designed to work with two components.

Work order

- The main component is loaded into the mixer from big bags.

- Premix is loaded from the bag spreader.

- The components are mixed in a mixer.

- The finished mixture is then transferred to a closed trommel screen where the lumps are sifted out.

- The finished mixture is then automatically loaded into big-bags and the lumps are loaded into other big-bags.

- All lines are equipped with air filters + active aspiration system with two-stage air purification.

View the news story with photos at Synergy Plant.

Equipment composition

- Rastarizer of big bags. (AAMix, Russia)

- Rastarizer of bags. (AAMix, Russia)

- Screw conveyors. (ВАМ, Italy)

- Mixer of dry mixes. (AAMix, Russia)

- Air filters Airklin. (AAMix, Russia)

- Closed drum screen. (AAMix, Russia)

- Packers of big-bags. (AAMix, Russia)

This is the most basic line, modifications are possible:

- Crushing lumps and recycling the material back into production.

- Packing immediately into bags (polyethylene, paper boxes, etc.)

- More incoming components.

Line models

This equipment for the production of washing powder is installed and operates at the client (since the project is under NDA, we can not give the name).

View the news story with photos at Synergy Plant.

How to buy equipment

To order and purchase call tel.: +7 (812) 408-41-82 or write to info@isilos.ru.