In this article, we will describe the principles of work and compare the two most popular packs of bulk materials in valve bags:More

What is the principle of action and what are they facing?

Both packages transfer a dry mixture to the valve bag using a special rotor and air.

Both packages transfer a dry mixture to the valve bag using a special rotor and air.

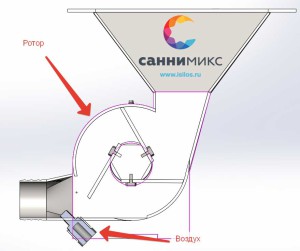

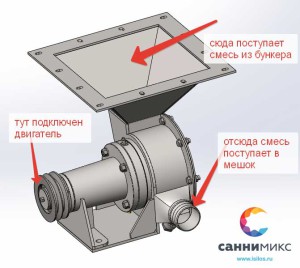

As you can see on the scheme on the right, this is the main node of the packing machine. Material for packing (dry mix, cement, sand, etc.) are located in the bunker from above.

When the installation is turned on, the rotor begins to rotate + the air supply is turned on to increase the fluidity of the powder and increase the pressure.

Under the influence of these factors, the mixture begins to enter the pipe of extradition on which a paper valve bag is wearing.

Paper valve bags are specially produced for this type of pack. All cement And dry construction mixtures that you buy in stores are packed in paper valve bags. The bags are ordered in specialized companies and when ordering you can choose the quality of the bag itself + print your contact details, logo, mixture name, etc. on it.

And dry construction mixtures that you buy in stores are packed in paper valve bags. The bags are ordered in specialized companies and when ordering you can choose the quality of the bag itself + print your contact details, logo, mixture name, etc. on it.

Send a request for a selection of packages online

What depends on the speed of packing?

The speed of packing depends on the speed of supply of material to the bag. Many manufacturers declare different packing speed, which they indicate simply for advertising purposes. After the purchase, it turns out that this is simply the declared performance under some ideal conditions, namely, in your production, the package will be packing 2 or 3 times slower.

So, the speed of packing depends on how large the diameter of the rotor and the pipe leading to it.

If the rotor is vertical, then the diameter is 90 mm, and if horizontal, then 260 mm. That is, installations with a horizontal rotor are more productive.

So, the main difference in installations:

- AAMIXMIX FAS COM2– vertical rotor (less productive)

- AAMIXMICS FAS-KM4– horizontal rotor (maximum performance)

What depends on the accuracy of the package and how is the weight measured?

When the bag hangs on the pipe through which a dry mixture is supplied to it, this pipe is attached to the frame through the tensodel, which continuously supplies information about weight in the control controller.

Through it, we can stop the feed at any time. That is, if we need to gain 25 kilograms, then when this weight is reached, the controller will turn off the feed and give the command to take off the bag.

However, the question is, how accurately the dosage will happen? The answer is if you do not take special measures, then not very accurate. For example, with a typical supply of material with one speed during a mining of 25 kg. The scatter can reach 1-2 kilograms.

What are the reasons for the inaccurate production and how to fix them?

- Large feed speed + inertia. When the weight reaches 25 kilograms and the stop command is served, the rotor is still spinning and the material goes. Usually they make an average stop time. For example, we see that after stopping, on average, another 2 kg is gained. Then we submit a stop command when reaching a weight of 23 kg. But this is not enough, all the same, the accuracy is +-1kg.

An additional solution is two speeds of work. For example, when adding a bag of 25 kilograms, the first 22 kilograms are filled at high speed, and when this weight is reached, slow speed is turned on, which allows us to produce a more accurate dose.

PECULIARITY!Aamix and European packs have. Adjusting the speed at each stage.

That is, the installation has two speeds + you can configure each of them. For example, make the first slower, and the second is faster. This allows you to adapt the installation for any tasks and materials. Indeed, when packing sand, accuracy is not so important, the speed is important, and when packing the spell, accuracy is very important, since the material is expensive.

Read more about the program and remarks of our packages >> - Sticking the material on the pipe and fastening. For example, you started a shift when there was nothing in the pipe and the whole installation was clean. However, already on the second bag in the pipe there are remains of the material, and on 1000 bags the dust was also settled for fasteners, etc. That is, the mechanism began to weigh 1 kg more and, accordingly, when adding into the bag, it will fall per 1 kg of material less, since this weight will be taken into account by the controller.

To fix this, there must be a function of periodic overwhelming weight without a bag. Which is very conveniently done in the Aamix installations.

Work algorithm and management

Pogos usually make the simplest management, which is clearly not enough for normal work with modern competition. It is important not only to dose accurately and quickly, but also to quickly adjust the installation and conveniently calibrate the scales (which is usually a whole problem).

Algorithm for the work of packs Aamix

- The bag is put on the pipe

- The clamp is automatically triggered and the package is launched

- A full cycle is worked out (two speeds, air, packed with a given accuracy), about 6 seconds

- The clamp is automatically released

- The pusher throws the bag

- … go to paragraph 1

That is, in the whole process one manual operation, which is also automated by a separate installation of putting bags (see below the video).

Control

Management and setting up the package is made from the touch of the panel, as on a tablet. Everything is clear and can be done by any reasonable acquaintance with phones. Settings:

- Setting speed setting

- Adjusting each speed

- weight setting in which slow speed is turned on

- Air shutdown setting

- Libra zeroing during work

- Libra calibration

Management screens

Automatic putting bags

Packing KM2 and KM4 can be equipped with installations for automatically putting on bags. This solves the main problem of production of dry building mixtures – the operator’s work in difficult conditions.

Conclusion

Packing KM2 and KM4 have only one difference – the type of rotor and performance. All other parts of the packages, weight module, control automation, etc. – Everything is the same.

Therefore, the choice of installation depends on the required performance.

Aamix packages have been working at industrial enterprises for many years and engineering, service and production experience are concentrated in them. We can safely say that in service, accuracy and reliability, we adequately compete with the best European manufacturers.