AAMix Plant has been manufacturing equipment since 1998. During this time we have supplied both individual units and complete plants to hundreds of enterprises in Russia and abroad. Equipment for food industry is completely manufactured at our plant. Our engineers have high competence in design and production, which we have developed over 25 years.

We manufacture equipment for different working conditions and for different chemicals. We use stainless steel or ordinary steel, depending on the requirements.

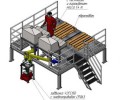

We also do complete industrial engineering for food processing lines and plants. That is, our customers receive a complete plant design, we manufacture the equipment, supply and supervise the installation.

To order tel.: +7 (812) 408-41-82 or info@isilos.ru

Food processing equipment

|

Clod chopper – LBC gate valve |

For crushing lumps when transferring bulk materials from silos, big bags, etc. Manufactured by WAM, Italy. |

|

Butterfly valve VFS (WAM, Italy) |

VFS butterfly valve with actuators and sensors. |

|

AAMix knife gate valve, model KV |

Quality knife gate valves with cross-sections up to 1000mm. Different actuators, position sensors, robust design. |

|

Gate valve VG (WAM, Italy) |

Gate valve with actuator and sensors. |

|

NoriMix model |

For sand and any other materials, length from 5 to 30 meters, capacity up to 30 tons per hour. |

|

Roller conveyors |

reliable roller conveyors in various sizes |

|

Belt conveyors |

Belt conveyors are available in three types – with straight belt, concave and concave chevron belt.Possible length from 3 to 120 meters. This makes it possible to solve any range of tasks. |

|

Modernization and restoration of Haver & Boeker and other foreign manufacturers’ filling machines |

Modernization of control panels, pneumatics, weighing systems, mechanics. |

|

FAS-KM4 – valve bagging unit |

The most productive filling machine, sales leader. Fills valve bags up to 15 tons per hour! High accuracy, speed, reliability, tested in many factories. Full automation. |

|

FAS-KM3 Euro, analog Haver & Boecker – plant for packing dry mixes |

Packing into valve bags of mixtures with coarse fillers – expanded clay, perlite, vermiculite, etc. Fully automatic, up to 8 tons per hour. |

|

Equipment for packing grain into bags FAS-OM1 |

Grain placement in open sacks – parallel weight metering, automatic sealing and / or stitching. |

|

Big-bag loader |

Reliable and functional big-bag filling station. |

|

Rasterizer for paper sacks from 10 to 50kg Prof Mesh-R |

industrial paper sack washer from 10 to 50 kg with all kinds of powders |

|

AAMix Big Bag Spreader |

Very reliable and well thought out big bag spreader. Aspiration, protection, reinforced construction, load cells for weight measurement. |

|

Rotary feeder, sector gate RVC (WAM, Italy) |

sluice gate for gradual discharge of material into pneumatic pipelines or for bagging, with distribution unit for pneumatic pipelines |

|

RV sluice gate (WAM, Italy) |

sluice gate for gradual discharge of material into pneumatic lines or for loading into bags |

|

Circular vibrating screen KVS-1 |

For screening of difficult materials and in industries where tight packing and complete isolation is required. Screens materials with very small fractions of less than 0.1mm (e.g. chalk, microcalcite, etc.). |

|

VSMP vibrating screen for fine powders |

Industrial vibrating screen for screening fine powders. |

|

AAMix BG trommel screen |

sophisticated and productive trommel screens for industrial plants |

|

AAMix vibrating screen |

reliable and productive screens, standard and customized to meet individual requirements |

|

Bins and storage tanks |

Hoppers for storing and feeding materials. Different volumes and convenient configurations allow their use in lines and as stand-alone units. |

|

Washing equipment LMShch-1 |

Washing line with closed water cycle. Low water consumption, independence from external mains, high quality washing and sorting. |

|

Airklin Hard fan bag filter (versions 1 and 2) |

Two variants of exhaust filters, with capacities of 4000 and 11500 cfm/hour |

|

Airlink Smart filter for dispensers and mixers |

Reliable filter for dosing units and mixers, overall dimensions, pneumatic cleaning. It is used in CCC plants and other plants where dry materials are handled for installation on intermediate tanks, batchers, mixers, etc. |

|

Airklin Medium cement silo filter |

Cement silo filter, with auto-cleaning air, quality filter elements, capacity up to 9600 cubic meters per hour. |

|

AAMix Airclean Asp aspiration unit (versions 1 and 2) |

Performance aspiration plant with ultra-clean cleaning according to European standards. |