During the installation of our mixer (to replace the old American one) at Danogyps plant in Chebarkul(see news) our engineers took a photo of the equipment we supplied to this plant a year ago.

No problems detected after one year! We publish photos taken at the factory, one year after installation.

Bag spacers

Used to rasterize expensive additives that come in bags.

There are AAMix exhaust filters above the rasterizers so that the dust stays inside and then falls back into the rasterizer.

- Description and drawings of the bag washer. (100% AAMix factory components)

- Description and drawings of the Airklin Hard exhaust filter. (100% AMMix and Russian Federation components)

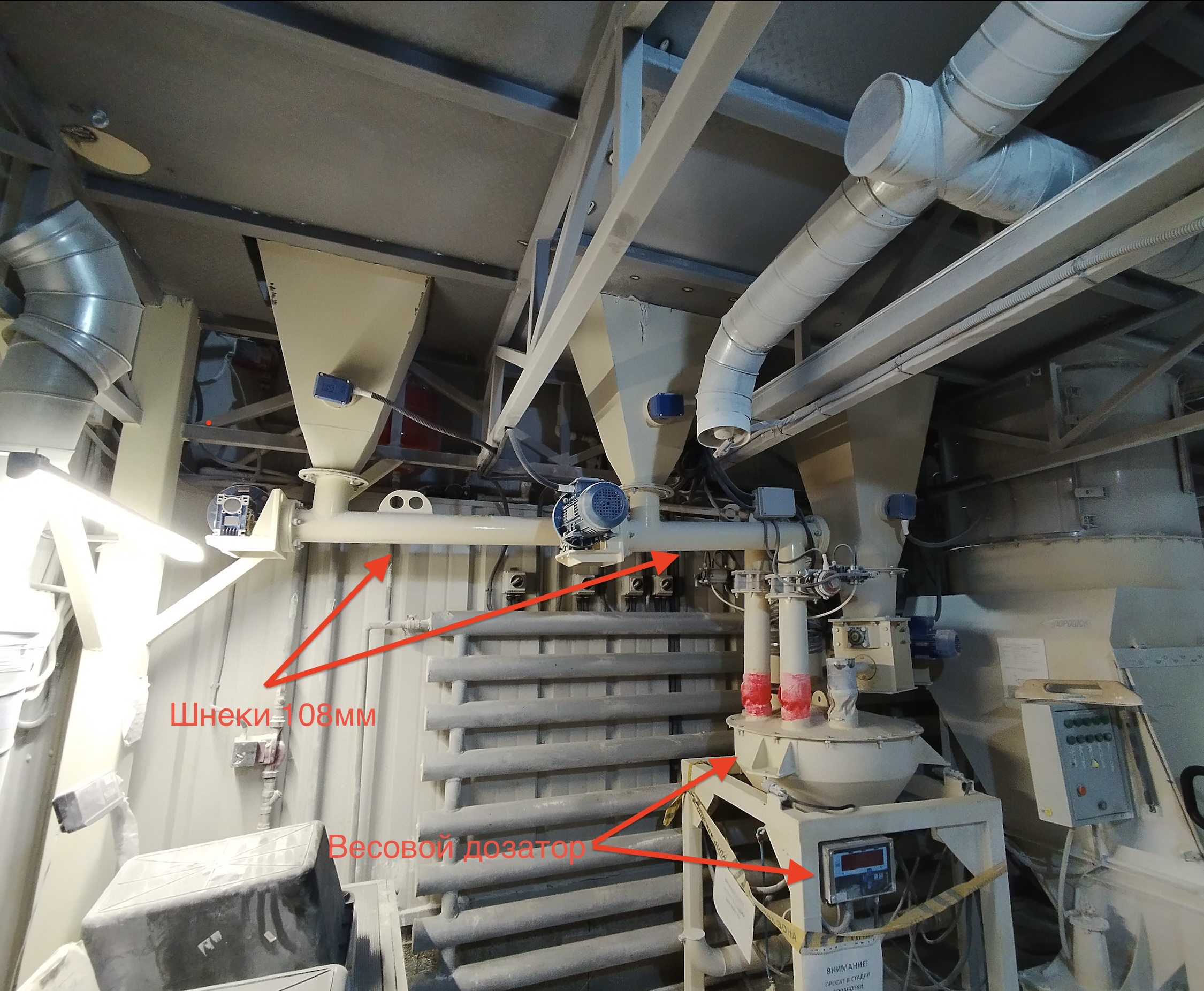

Screws with 108 mm diameter for precise metering

These augers are our pride. Very few companies in the world produce screws of this diameter. We produce them entirely in our factory, production starts with sheet metal cutting and all other cycles are also in our workshops. Motors and gearboxes are made in Russia.

The augers very accurately dispense components from bag spacers into the weigh dispenser.

Weight dispenser 60 liters (picture above)

The dispenser accepts additives from three bag spacers. Two additives are fed by 108mm augers, one additive by a microdosing unit (description below).

The doser allows very precise dosing of additives and further feeding of additives to the production cycle.

- Description and drawings of pipettes (manufactured by AAMix plant, load cells Tenso-M, RF)

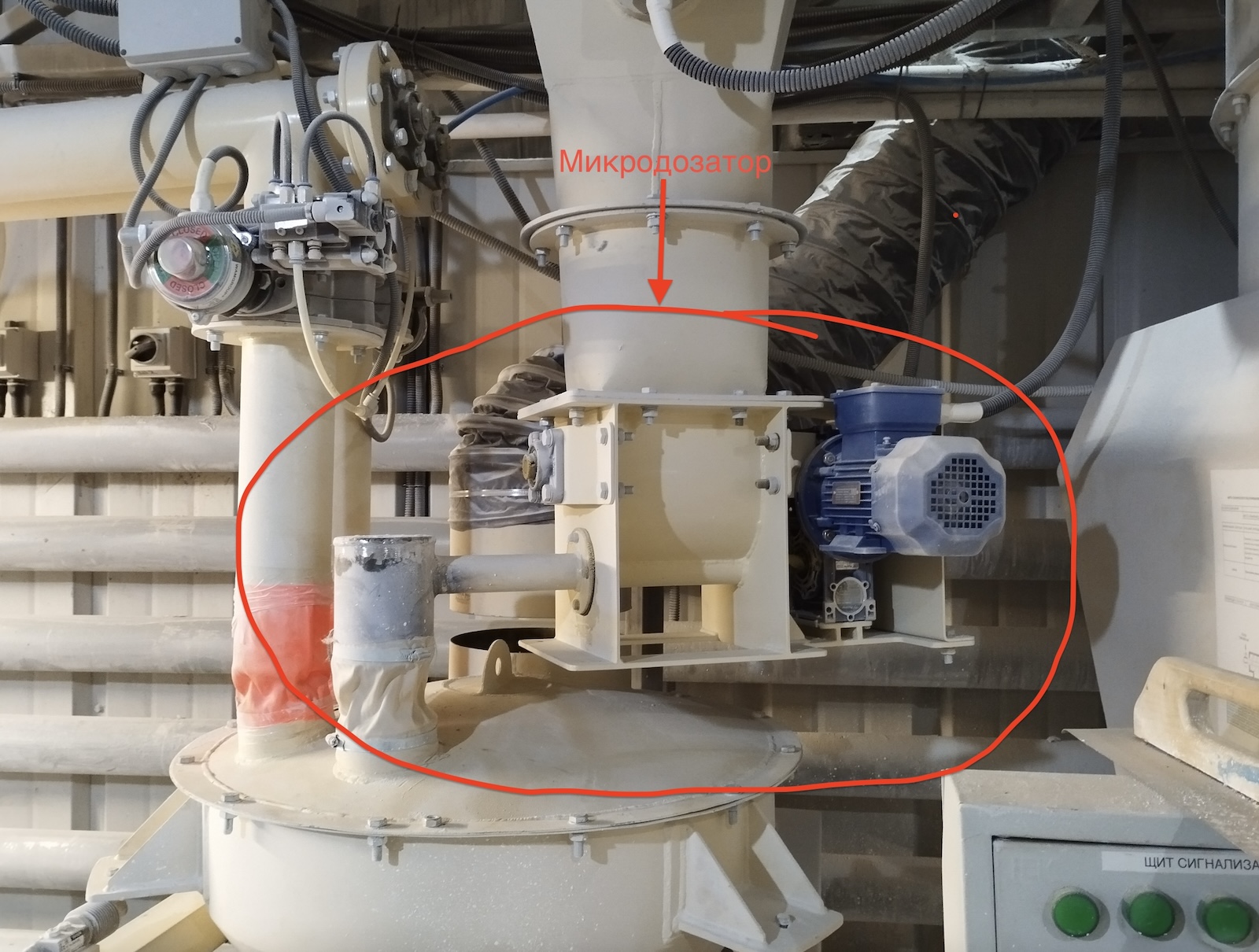

AAMix Flow M42 additive microdosing unit

This dispenser, due to its special design and special spiral attachment, can feed lumpy additives.

Used for additives that cannot be conveyed by screw conveyors.

- Description and drawings of microdosing machine (AAMix plant, motors made in Russia)

Weight dispenser 2 cubic meters.

Standard weight dispenser. Feeding is done by screw, excess air is filtered by Airlink Medium filter. Production of our factory. Tenso-M load cells.

- Description and drawings of pipettes (manufactured by AAMix plant, load cells Tenso-M, RF)