The company Spatler, one of the manufacturers of dry construction mixtures of St. Petersburg, has been operating since 2013.

Since their Haver fills had worn out, they ordered replacements from the Chinese branch of this company and wanted to replace them urgently.

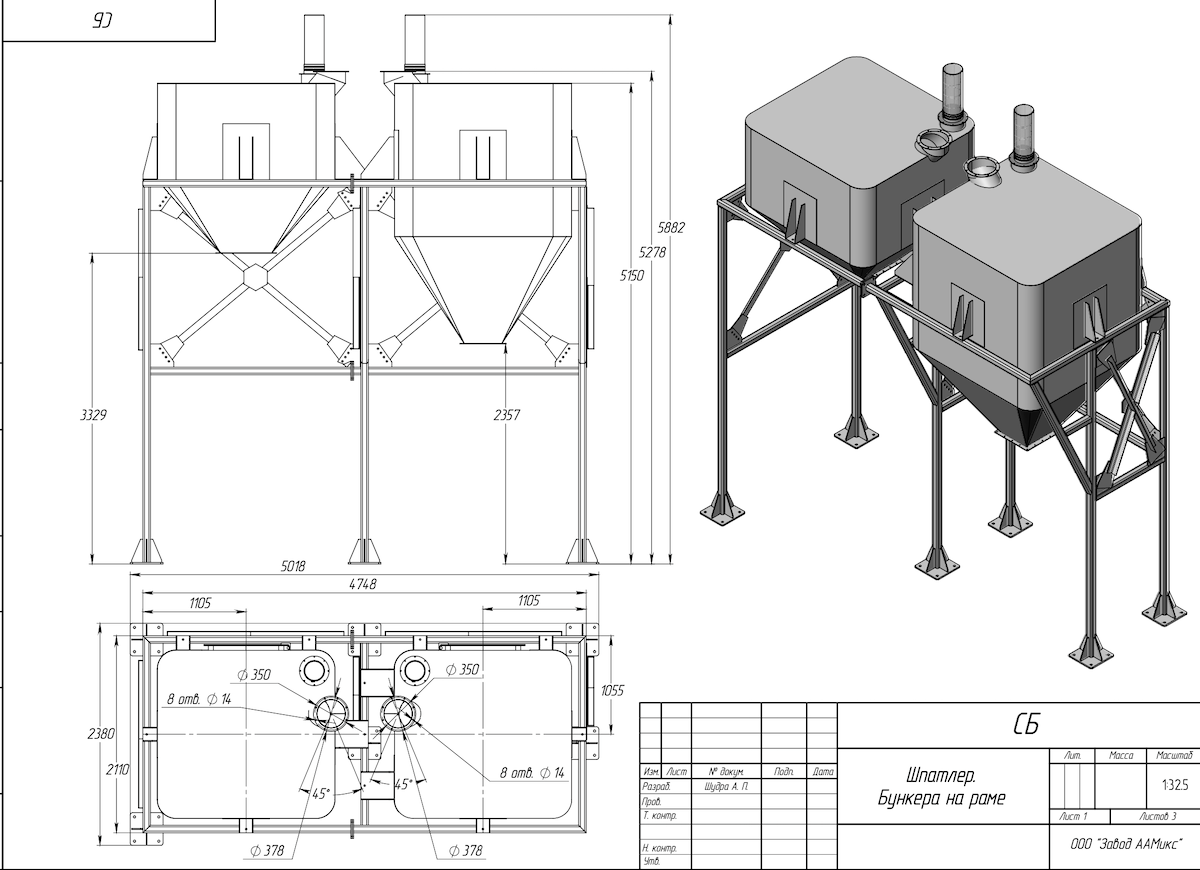

We have been working with them for many years, since about 2014. In November 2023, Spatler was asked to design all the hoppers, crossings, gate valves, and aeration for the new baghouses, connect them to the existing line, and add big-bag bagging.

The deadline was tight, we needed the installation at the end of January.

In two months, we made a design based on measurements at the production facility, approved it, manufactured the equipment and made the installation at the end of January 2024.

At the moment, the equipment is operating normally and the company has avoided major losses due to the downtime.

AAMix KV gate valves were used for the hoppers above the fills.

Drawing

installation process

installation process

installation process

mounted system