Tray augers are used for horizontal movement of bulk materials over short distances.

Tray augers are used for horizontal movement of bulk materials over short distances.

They are also easier to maintain as it is possible to remove the top cover.

AAMix factory produces tray screws with diameter 114, 159, 219, 273mm. We also produce other sizes to the required parameters.

Production

Screws are produced at our own full cycle production facility (starting from metal cutting) in St. Petersburg. Production time from 2 weeks, depending on load and quantity.

Modern technologies are used in production of AAMix plant, full quality control is carried out – welding seams, assembly, painting are controlled.

These augers are already supplied to KNAUF plants, which indicates quality and reliability. See news item.

Technical specifications

The AAMixFlow tray auger consists of:

- Trough-shaped casing (tray) with length from 1 to 12 meters.

- The loading dome.

- Discharge window.

- Spiral screw mounted inside the housing.

- End and intermediate support bearings with spacers.

- An electric motor and a worm gearbox connected to the shaft axis.

Performance Material:

- High quality carbon steel.

- Stainless steel.

News about the delivery of a tray auger for KNAUF.

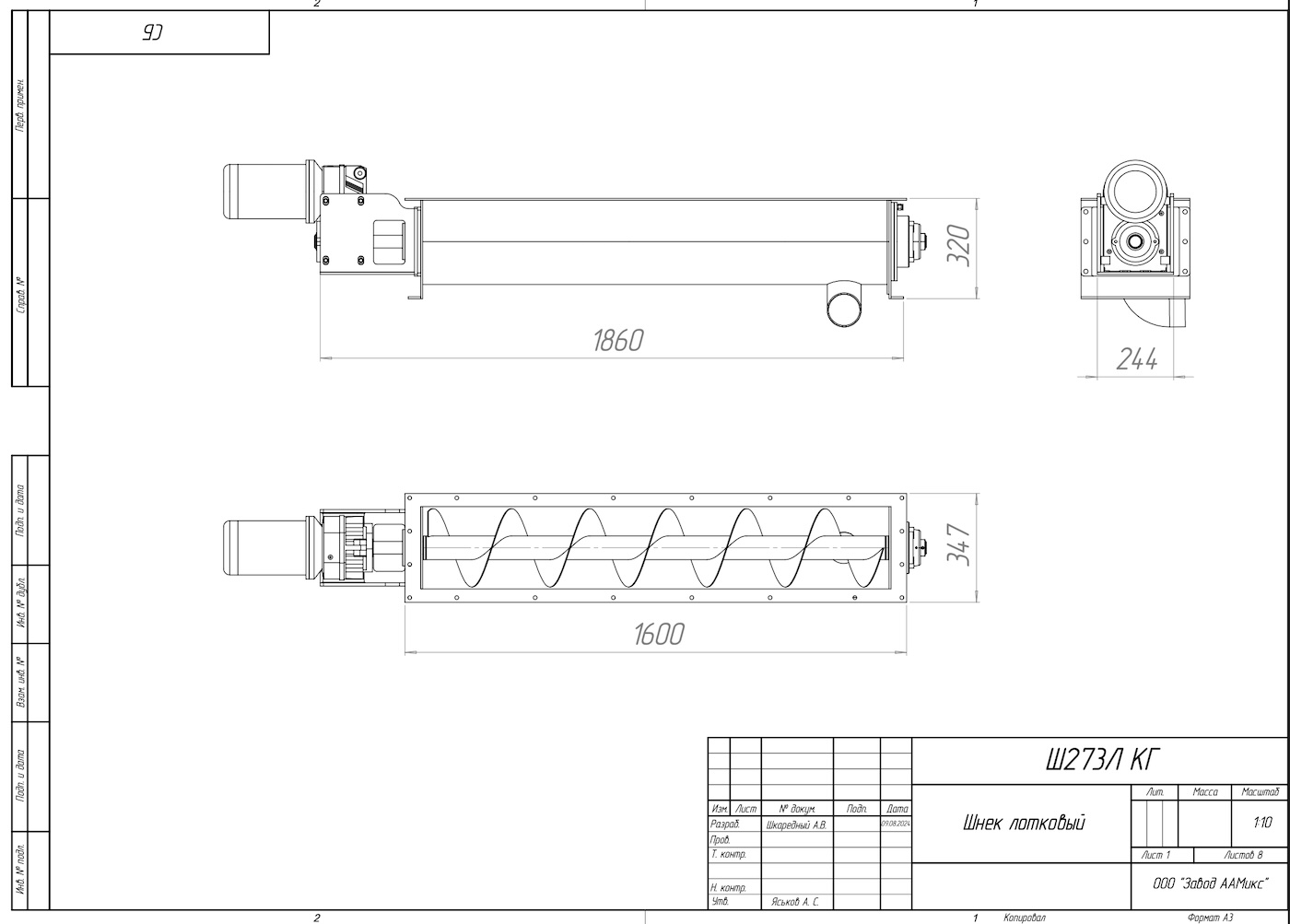

Drawing

Drawing of a typical chute auger – we produce different diameters and different lengths, the drawing is provided for reference.

Order and price

For ordering and cost calculation write to info@isilos.ru or call tel.: +7 (812) 408-41-82.