AAMix factory has accumulated vast experience in the manufacture and installation of drying drums and auxiliary equipment.

AAMix factory has accumulated vast experience in the manufacture and installation of drying drums and auxiliary equipment.

We manufacture industrial drums with capacities from 5 to 50 tons per hour. We not only manufacture drying drums, but also design drying areas, fully automate them and integrate them into existing lines.

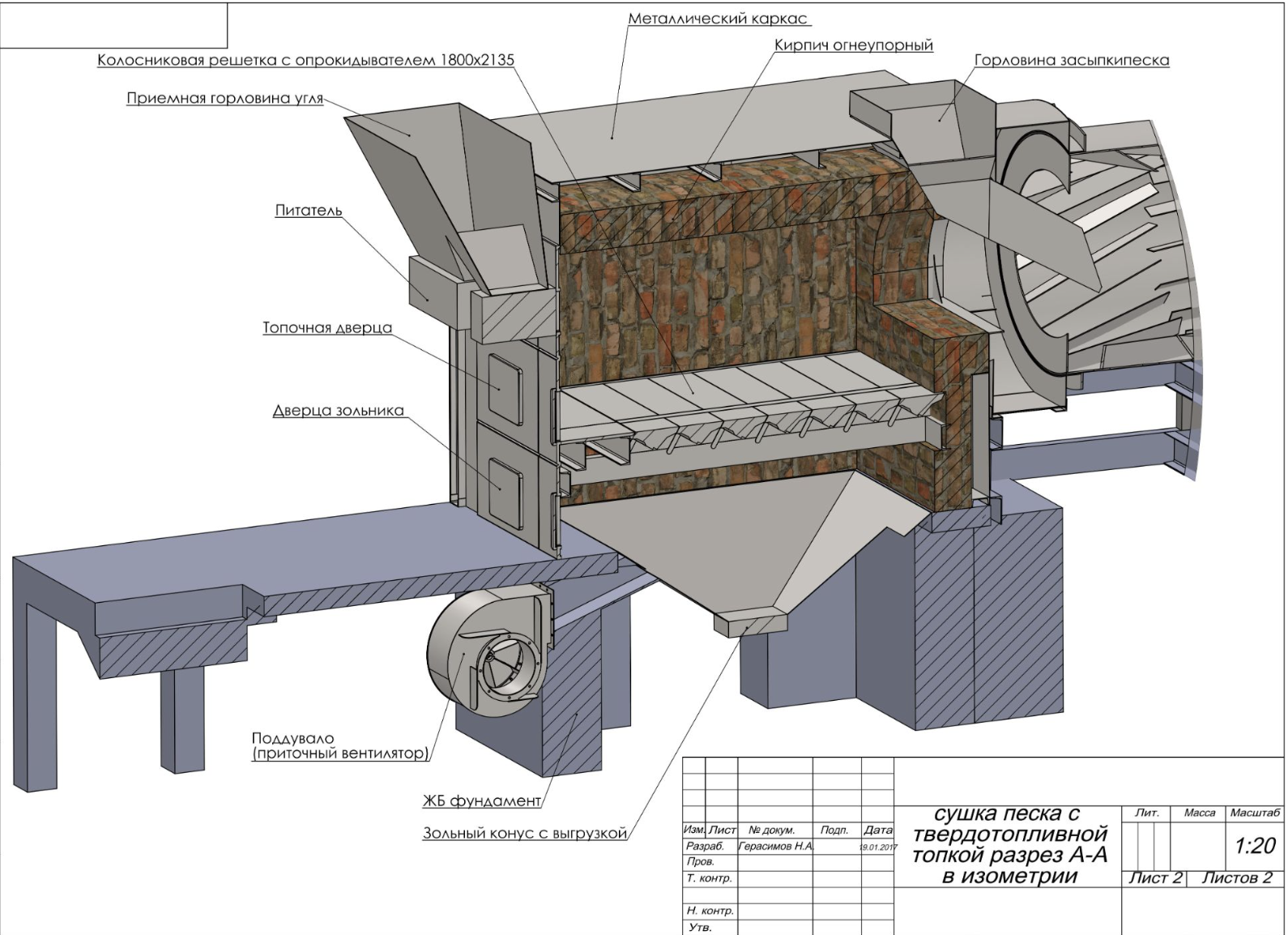

Unique! We make drums that run on electricity, coal, gas, diesel.

Among the realized projects are

- Electricity-powered drying drums (for low-cost regions, we implemented this project in Norilsk.

- Drying drums on coal. We implemented this project in the city of Abakan, for 2024 is successfully working.

- And also classic fuels – gas, diesel.

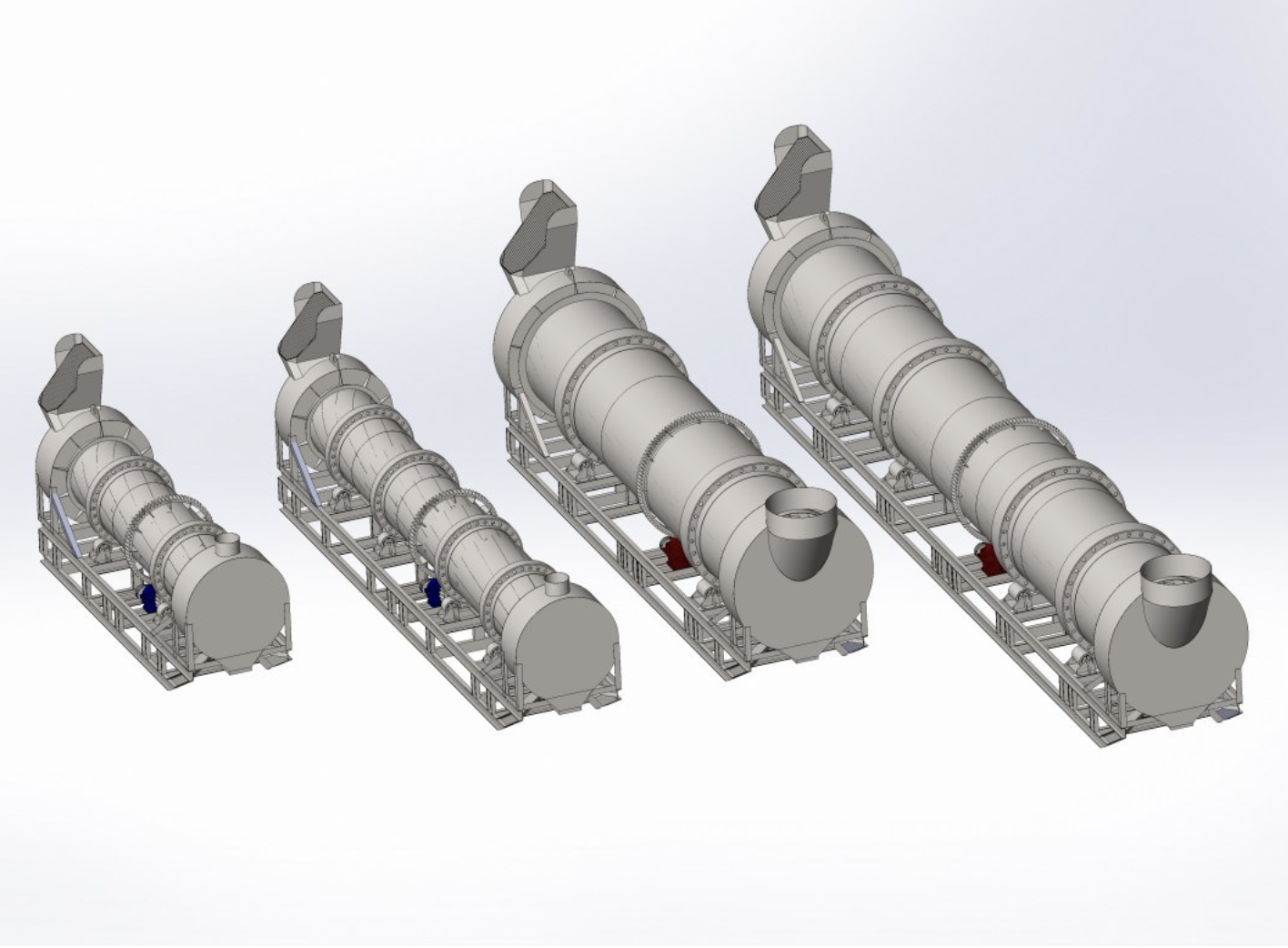

Types of drums produced

- From small ones with a capacity of 5 tons per hour, 950 mm in diameter.

- Up to large ones with a capacity of 40 tons per hour, with diameters of 1500, 2200, 3500 mm.

Design, engineering

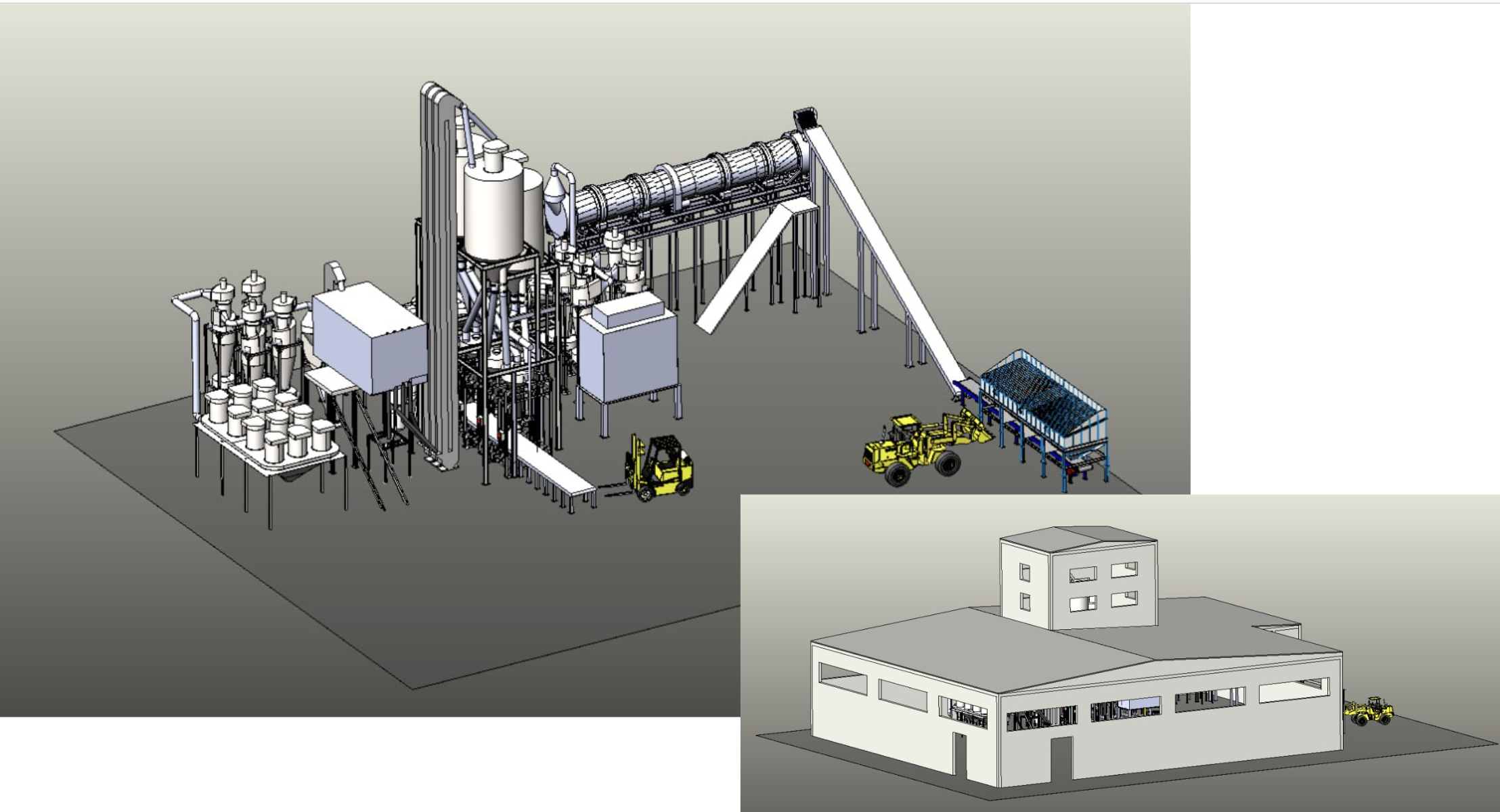

Any drying area implies the creation of a project, engineering. Our engineers and designers with vast experience take measurements, make a scheme, aglgorithm of work. And after that an accurate 3D model of the project and a set of drawings are created.

Then, after coordination with the customer, we manufacture and install the equipment.

A classic drying section consists of

- Rusting sand out of trucks – options.

- Feeding sand into the drum.

- The drum itself with powerful aspiration units.

- Fractionation (sieving).

- Feeding into storage silos (conveyors, elevators).

Where our production is located

NPO AAMix produces all types of this equipment at its full-cycle production facility in St. Petersburg. Localization of these types of equipment is 100%.

The drying section is also equipped with full automation, all data is collected by AATech’s automated process control system and further transferred to any MES system.

How to buy a drum or order an upgrade

For ordering and cost calculation write info@isilos.ru, Telegram https://t.me/aamixru or call tel.: +7 (812) 408-41-82.