The Aamix plant has been producing its own silos and aspiration stations for 10 years.

Sales were not high and basically we supplied aspiration stations assembled. We have completed our own packing nodes of dry building mixtures. They have established themselves well, which, in conjunction with competitive value, made them known.

In 2022, the geopolitical situation became very aggravated and the issue of import substitution among our customers became a priority.

The Aamix plant updated the proposals on the filter, both in the price segment – reducing the cost and in high -quality.

Today we offer a full range of Aerklin filters for all tasks:

- Aerklin Smart– filter for dispensers, small bunkers;

- Aerklin Medium– Silosov filter;

- Aerklin hard– A filter with an exhaust fan for difficult working conditions.

Smart

Smart

Filter Smart (pneumatic cleaning, automation) is installed on intermediate tanks, dispensers, mixers and other plants of factories where the bulk material comes. When the materials are presented in the container, excessive pressure is formed, which goes into the room without a filter and excites it greatly. The filter uses the same cartridges as in large phyrts, so it is easy to serve.

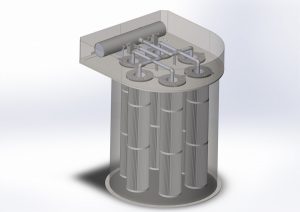

Medium

Medium

Aerklin Medium (pneumatic cleaning, automation) also has two modifications: with a filtration area of 24 m2and 12 m2. The dimensions are standard for this type of product, a diameter of 800 mm, which allows you to install it on all regular places of fasteners, where foreign analogues previously stood.

Used for installation on silos and other large containers.

Hard

Hard currently has three types, but the Aamix plant does not stop there. All non -standard filters and filters on an individual order are made in this type. For example, the third type is designed to work with dusty air of high temperatures 250-300 degrees Celsius. In this modification of the filter, in contrast to all other types and types of Aerclin, a filter of bag of fiberglass is installed. This of course greatly lowers the index performance-Gabarit of the filter, but this solution is optimal.

All the Aerklin line filters have a galvanized main case made of steel 2 mm thick and steel lids covered with powder color. This solution slightly increases their weight compared to competitors, but it gives good protection both from weather and from external mechanical damage. It is not uncommon to find filters on silos with puffy and pressed buildings. All internal elements also passed sandblasting and powder coloring.

Filter cleaning occurs in a built -in purge system with compressed air. It is carried out cyclically or forcibly an external source of the electrical signal. In the filter control panel, all parameters are adjustable and there is a digital screen. By default, power is 24 a direct current, but it is possible to replace this parameter with 220 volts of alternating current when ordering. We recommend this only in case of emergency, since it is better to provide a low -voltage connection for employees’ safety, especially if the filter is installed at a height.

In the modifications of hard, it is possible to use the vibrational method of cleaning by installing a low -power vibrator on the supporting platform of cartridges.

Large receivers of compressed air on the medium and Hard are equipped with cranes of condensate discharge. At least once a month it is necessary to open them and drain the accumulated moisture.

At the moment, the Aamix plant can produce up to 50 filters per month and can quickly increase the capacity to a large amount. Constantly in the warehouse there are Aerklin Smart 2 and Medium 2, all spare parts for filters. This allows us to see in our person a reliable supplier and assistant to solve your problems.

Airklin filter line

- Aerklin Medium– Silosov filter.

- Aerklin Smart– filter for dispensers, small bunkers.

- Aerklin hard– A filter with an exhaust fan for difficult working conditions.

- Price list.