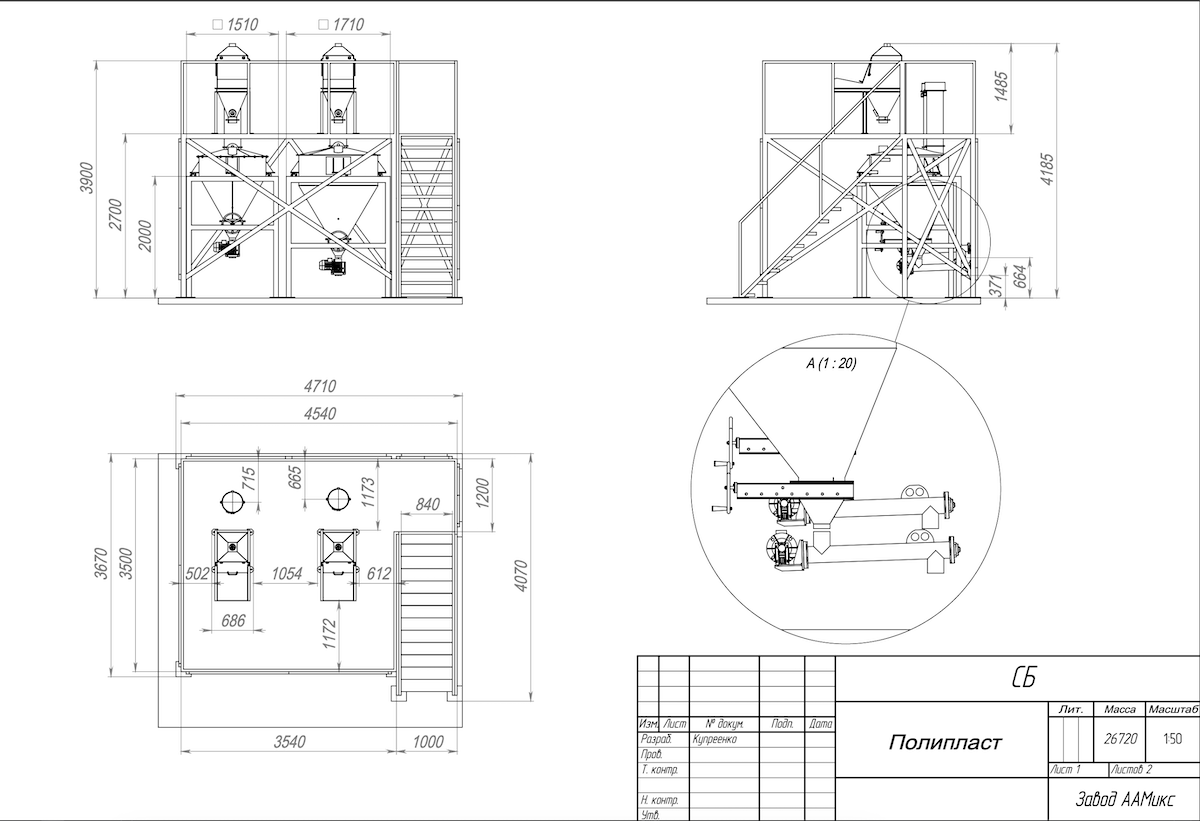

The largest manufacturer of plasticizers in Russia,The company is polyplastI turned to the Aamix plant for the design and production of an automatic dosing line for components for the Soy plant of dry mixtures.

We developed a project, and technological solutions for dosage and microdation were selected. The project was approved, after which the equipment was produced, verified, and shipped to the polyplast Novomoskovsk (one of the holding factories) in a short time.

More

IMPORTANT!

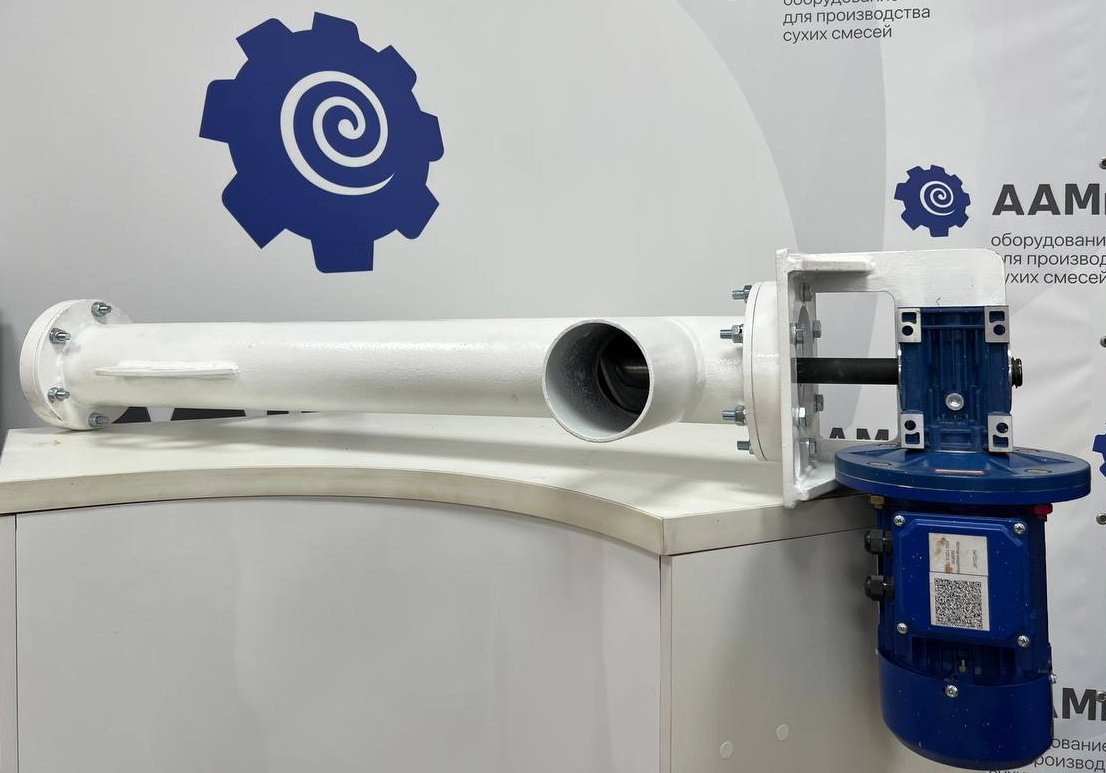

- For microdation, screws with a diameter of 108mm were used, which were 100% produced by the Aamix plant. Frequency converters are additionally delivered for accurate dosages, which automatically adjust the speed of the screws. For example, when at the end of the dosage to “catch” accuracy in grams.

- Also at the Aamix plant, automation with control shields is carried out. This project used sensors and production modules of Tenzo-M (Russia). All modules are connected to the central system of the plant for full automation.

Project

- They stand at the topBoarding paper bags(additives enter them).

- Of these, additives fall into storage containers.

- All air flows are filtered by filtersAerklin Smart.

- Next, 108mm screws (produced at the Aamix, St. Petersburg factory), a weight dashing in the mixer of dry mixtures is made with automatically controlled speed.

Photo shipping