Microding of additives is one of the most difficult in the implementation of the modules of the plant of dry building mixtures. In many industries, manual dose is still used with measuring containers.

Microding of additives is one of the most difficult in the implementation of the modules of the plant of dry building mixtures. In many industries, manual dose is still used with measuring containers.

However, with large volumes of production and complex recipes for the mixtures, this becomes unprofitable.

Over more than 20 years of work, we have developed two typical solutions for high -quality and accurate dutation of additives. These two options are designed for the different accuracy of the dosage. This is due to the accuracy of weight modules and tensodists.

The main problem in the dosage of additives in volumes from 100 grams per batch and above is that most systems cannot accurately transfer the right weight to the mixer. The additives can be fibrous, slightly sticky, uneven payment (with lumps).

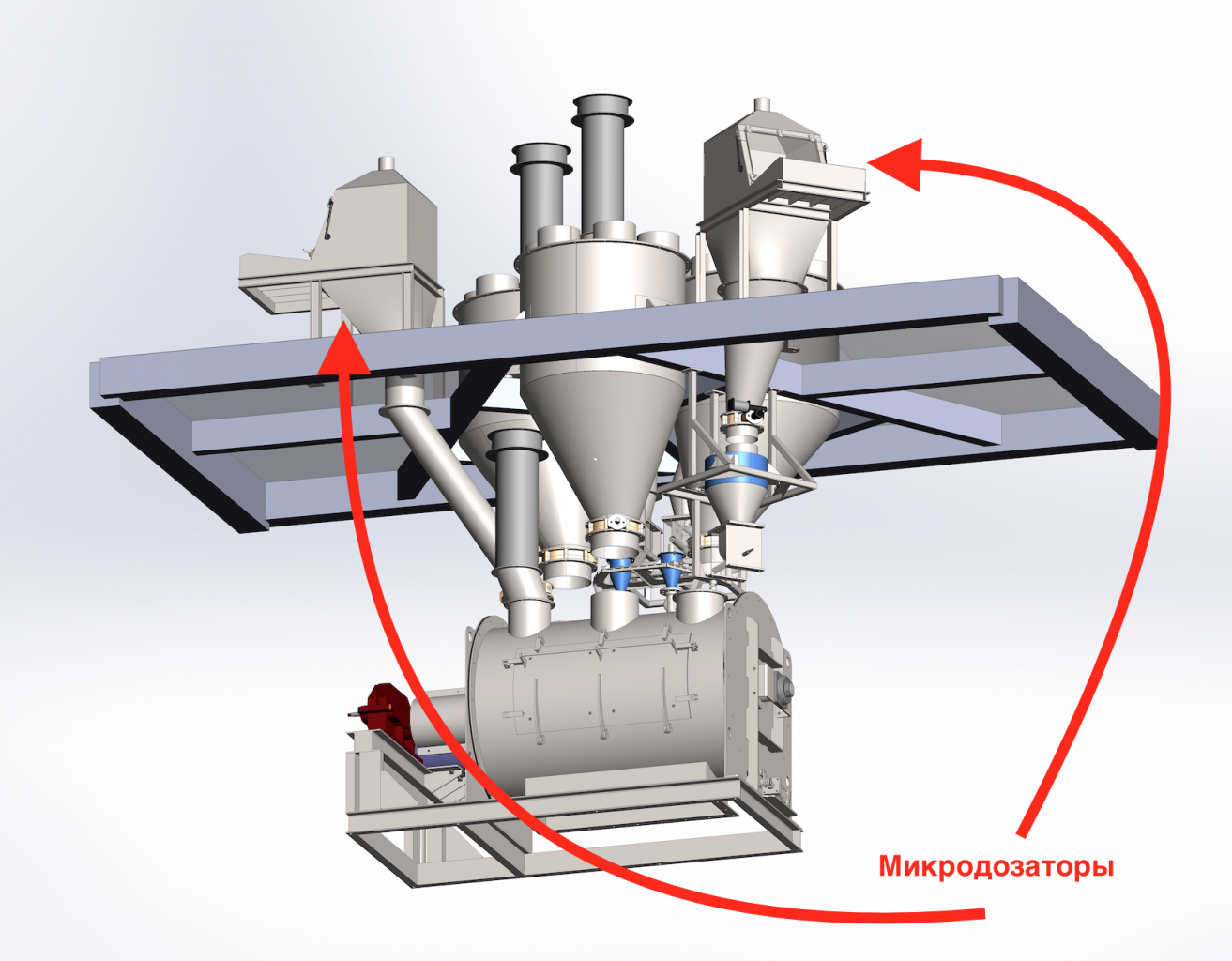

Therefore, even very goodAAMIX Flow M42 MicroderiesThey can give a significant error, as they work by time, and not by weight. And accuracy is very important for saving (additives are very expensive) and for the quality of the final product (affects sales).

Therefore, we developed a system that allows you to dose complex additives much more accurate.

The system is fully automatic and controlled from the central remote control.

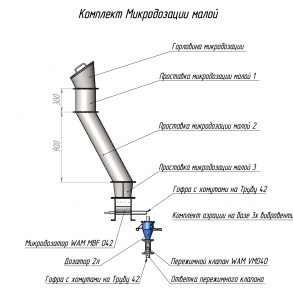

Microdulation AAMIX, small – accuracy +-3 grams

For accuracy +- 3 grams to the line, an intermediate weight module has been added. It was experimentally revealed that for 3kg tensodists, the error in the real conditions of the plant is +/- 3 gr.

For accuracy +- 3 grams to the line, an intermediate weight module has been added. It was experimentally revealed that for 3kg tensodists, the error in the real conditions of the plant is +/- 3 gr.

In this module, the dispenser transmits the supplement, and the factory program accurately sets up the system and the dosage occurs not in time, but by weight.

Complete

- Gorlovina member

- AAMIX Flow M42 Microder for Brewing Products

- Dispenser 2l

- 3 kg – 3pcs

- Sufferous valve WAM VM040

- Frame canopy for dispenser

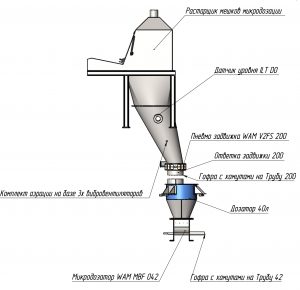

Microdation aamix, large – accuracy +-10 grams

For accuracy +- 10 grams also added a weight module. But in this embodiment, he faces the dispenser and the final calculation of what is transmitted to the mixer is in the weight difference in the bunker. This allows you to achieve accuracy +-10 grams.

For accuracy +- 10 grams also added a weight module. But in this embodiment, he faces the dispenser and the final calculation of what is transmitted to the mixer is in the weight difference in the bunker. This allows you to achieve accuracy +-10 grams.

For tenshoters 20 kg, the real error in production is 2g. +/- 10 gr.

Complete

- Meshsov mesh

- WAM V2FS 200

- Pneumo cylinder

- Mic 23

- Pneumatic distributor

- The coil of the Second World War 24

- Dispenser 40l

- AAMIX Flow M42 Microder for Brewing Products

- Weight sensor for 20 kg – 3pcs

- Frame canopy for dispenser

- Set of aeration system based on 3 vibrovalrators (coil 24V)

- Iltd0 level sensors

This system is fully automated and manual labor is required only for unpacking bags – feed, dosage, recipe – everything is controlled by controllers.

Addments are supplied to the drives in paper bags from 10 to 50 kg.

The Aamix plant develops and produces reliable and unique automation at its own plant for the production of building materials. Among our customers are firms as KNAUF, LSR Group and others.

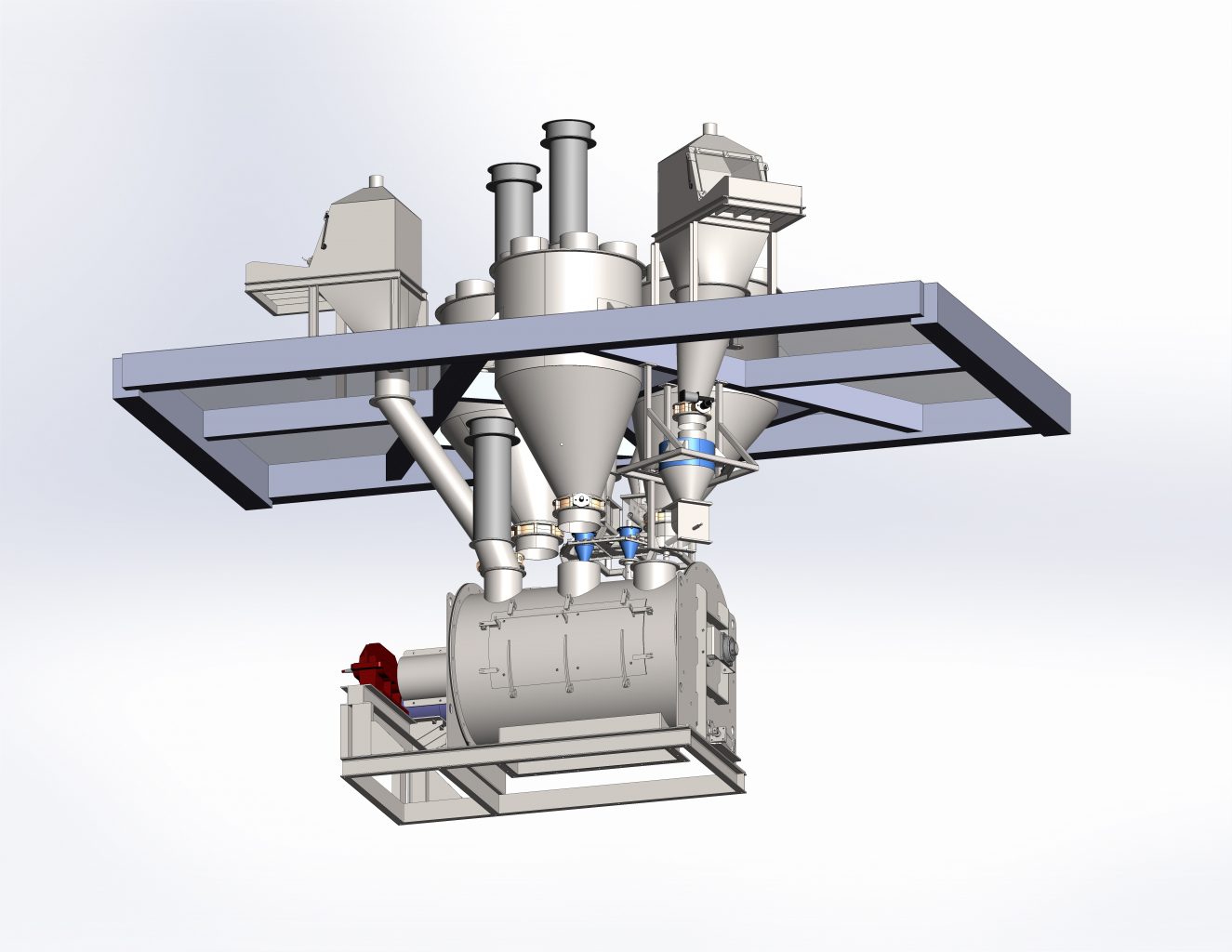

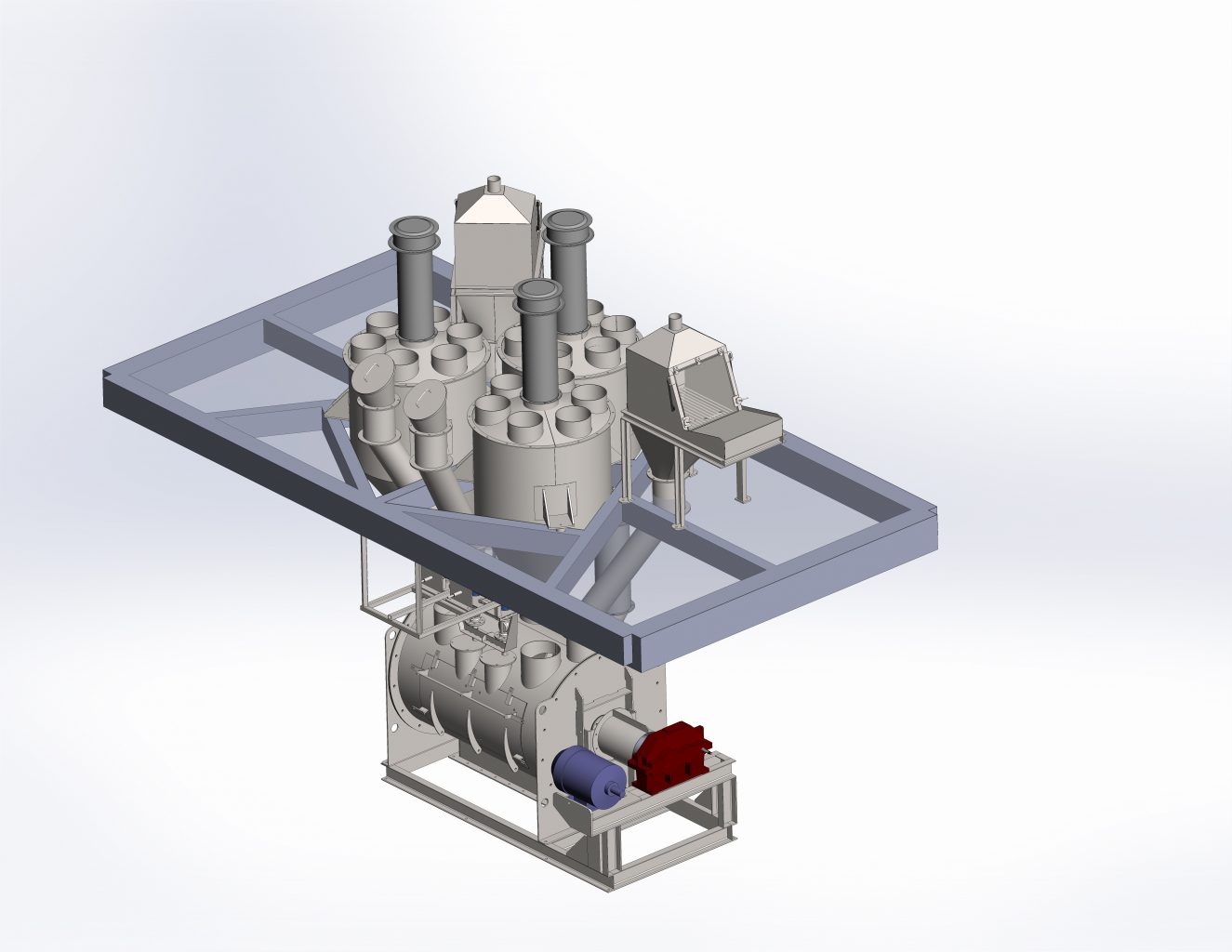

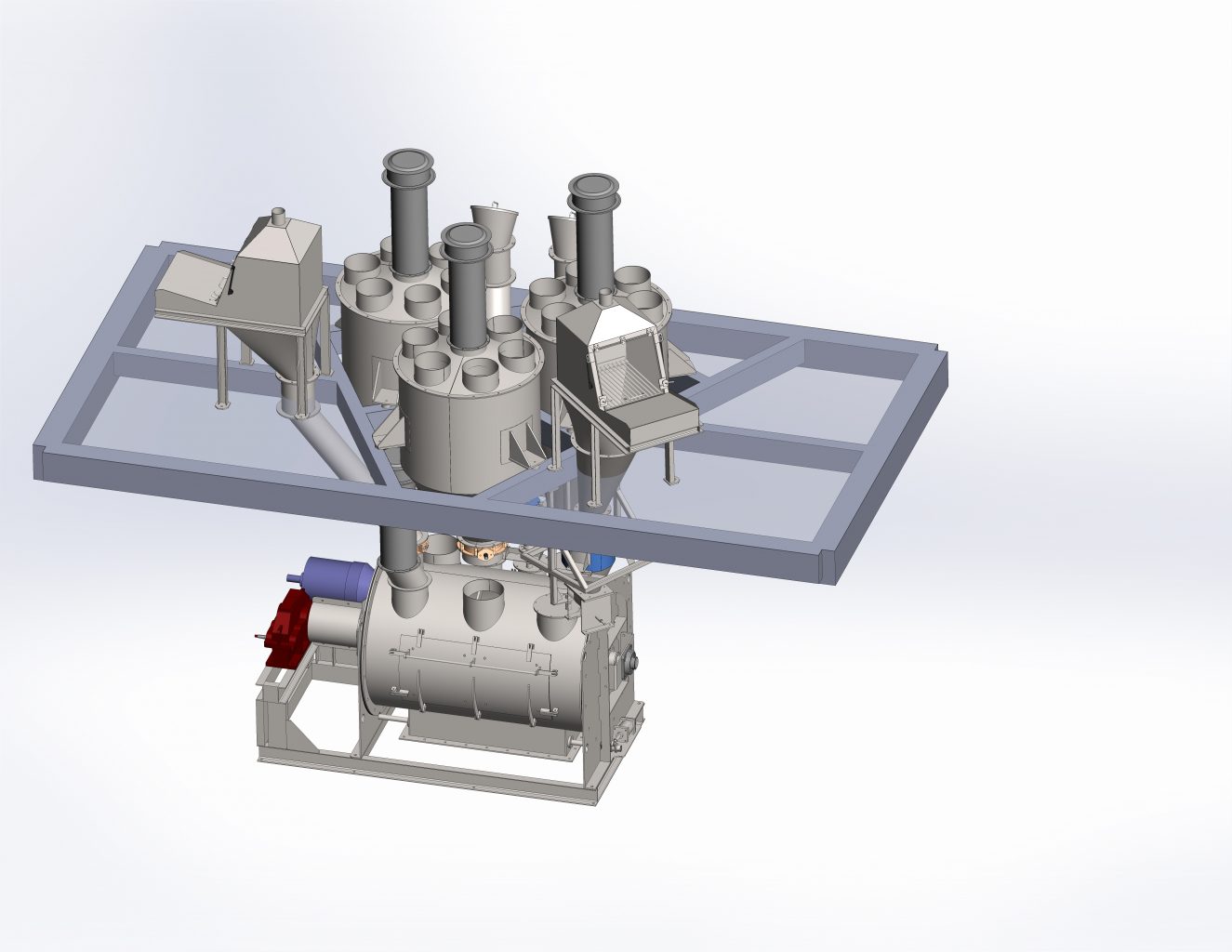

Model of DOSISE models at a real plant