For more than 12 years AAMix factory has been supplying equipment and lines for Danogyps (a division of KNAUF), where Danogyps putties are produced(link to Danogypscatalog).

During this time, together with our technologists and engineers, we have accumulated vast experience in the production of fillers – from receiving (loading and feeding) of raw materials, their transfer and mixing to filling (packing) into buckets and preparation for shipment.

Earlier, some of the equipment was supplied from the USA and Europe, however, due to the closure of supplies from abroad, we began to produce all the equipment in our own production facilities. Now we offer complete lines for the production of putties “turnkey” – starting from the design of the plant created according to your conditions and ending with installation, start-up and production of the first batches.

All equipment is manufactured in our own full-cycle production facility, automation and plant control is done on AATech industrial controllers, installation and start-up is done by experienced engineers.

How to order

To receive an offer for this line write to info@isilos.ru or call tel.: +7 (812) 408-41-82.

News about equipment deliveries to Danogypsum

Below is only public news, in reality we supply equipment to 4 Danogyps plants and deliveries are much more frequent.

- Report from Danogyps (KNAUF) plant on the work of dosing machines, bag spreaders, augers, microdosing machines

- Import substitution in action – installation of 2200 liters mixer completed, USA mixer replaced at KNAUF plant

- Developed and launched microdosing for KNAUF plant

- Launch of a sophisticated screening system for KNAUF

- Another order from KNAUF – a system for spreading, weight dosing and feeding into the pneumatic line

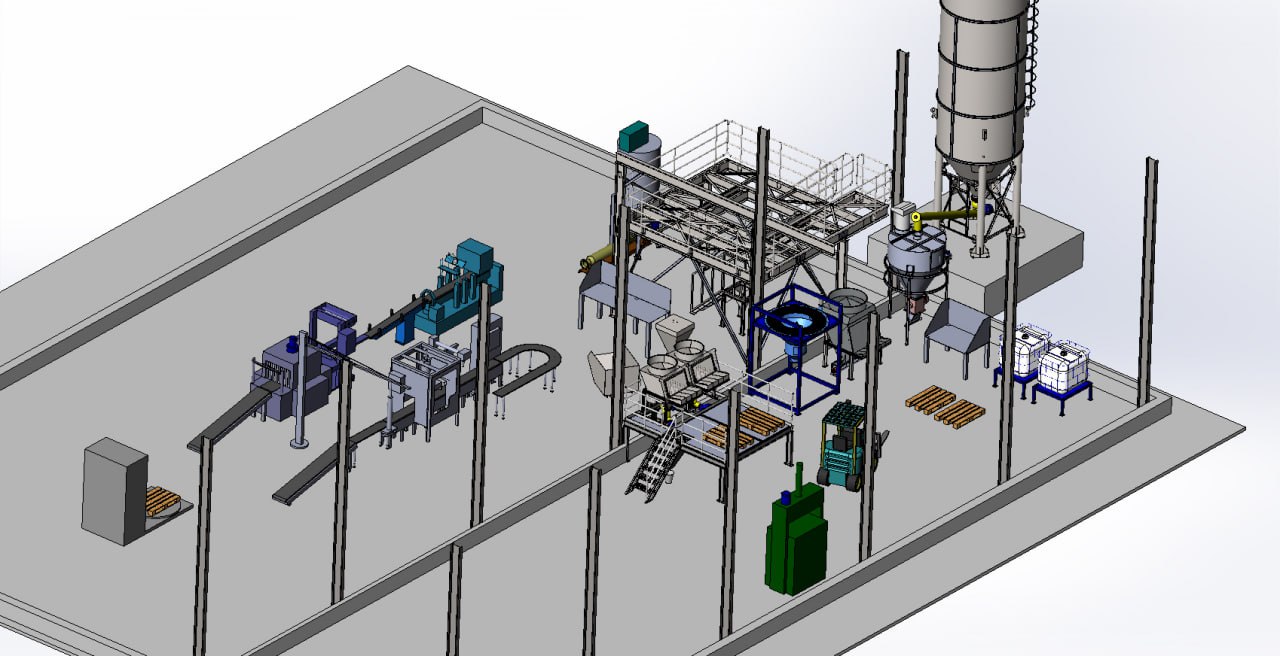

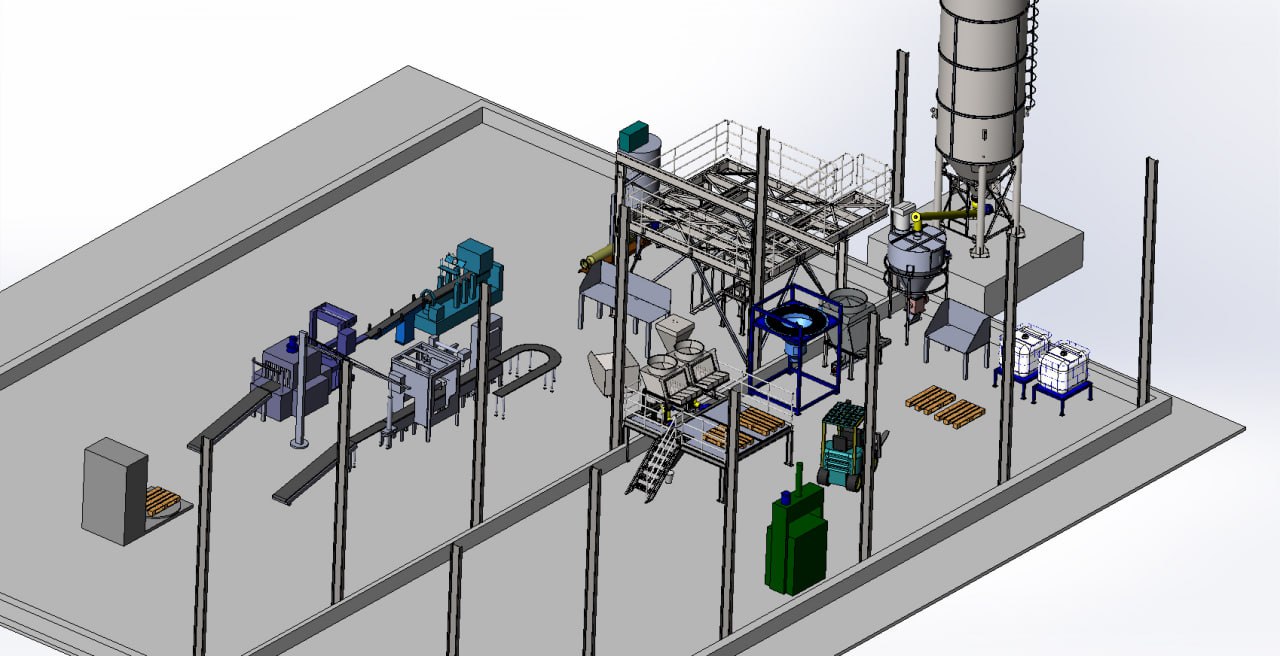

Putty production line

The following is a typical line composition, however, every plant is unique and for each order we make our own design and calculation. Some parts of the plant customers prefer to use their own, for example, when there are already existing batching and storage units. Then we customize the line to the given conditions.

1. Material receiving area

- Bag spacers with feed for weight dosing. Precise dosing down to grams. Used for automatic rasterization of bags with expensive additives.

- Big-bag rasterizers with feed to weight dosing.

- Silos (if necessary) and juggling from them into weight dosing.

2. Metering section

- Weight dispenser for bulk solids. It is placed above the mixer. All materials are fed into it and then poured into the mixer.

- Liquid additive dispenser.

3. Mixing area

- Powerful planetary mixer for mixing components. Capacity 2200 liters (may be different, depends on the line).

- Pump for pumping putty into the storage hopper.

4. Packing area

- Filling station for viscous products into buckets.

- Bucket feeding system on the belt.

- Lid feeding system on the belt

- Pneumatic bucket lid press or roller mill.

5. Management and automation

- The line is fully automated. Central control on a control panel with 27 inch industrial touch screen. All information is transferred to the MES system of the plant (if necessary). It is also possible to connect to the control via the Internet from computers, tablets, etc.

See a photo of our equipment at the Danogyps plant.

To receive an offer for this line write to info@isilos.ru or call tel.: +7 (812) 408-41-82.

Video about Danogyps plants made by our engineering and with our equipment.

How to order

To receive an offer for this line write to info@isilos.ru or call tel.: +7 (812) 408-41-82.

See also.