The Stroy-Baton plant develops and produces dispensers of bulk materials of any configurations and configurations.

Typical tasks when dispensers of bulk materials are used:

-

- Dosage of components in the production of building materials before applying them for mixing. For example, the dashes of cement, sand, additives before supplying them to the mixer for the production of concrete or dry mix.

- Dosage of grain, silage and supple materials. Usually used in the production of food mixtures, compound feeds.

Task

Production of a dry mixture, which includes 2 components – cement, ash. You must first weigh them, and then transfer them to the mixer for mixing. Ash requires 300 kg, cement 800 kg per cycle.

In this case, 2 weight dispensers with a volume of 300 and 800 liters are usually used, respectively. Both dispensers transfer weight to the central control panel.

The control panel automatically launches screw conveyors that serve components to the dispensers, and when the desired weight is reached, automatically turns them off.

After that, the automation of the remote control automatically opens the pneumatic changes of the dispensers and the components fall into the faucets.

Nuances

- When the materials are supplied to the dispensers in them, an excess of air occurs and they begin to “dust”. Therefore, the installation of filters on the capacity of dispensers is required.

- When unloading the components, they often “stick” and do not completely spill up. Therefore, you need to install vibrators that automatically start when a certain weight is reached, for example, when 30 kg remains in the dispenser.

There are also many other nuances that only professionals can take into account. We have been developing and supplying dispensers for more than 10 years and we know all the nuances!

News about shipments

For example, you can watch news with photos and projects about shipments to our clients

Send a request for a dispenser online

To order dispensers, it is enough to describe your task for us and we will make the best option for you.

Each project creates its own set of documentation, which is approved by the customer and therefore the manufactured systems fully comply with the tasks.

To order you need to fill out the questionnaire below, fill it out and send it either to fax (812) 331-99-46 or by e-mail: info@isilos.ru

- Download questionnaire for ordering a dispenser of bulk materials >>

- Download the description of dispensers in pdf >>

Examples of projects and prices

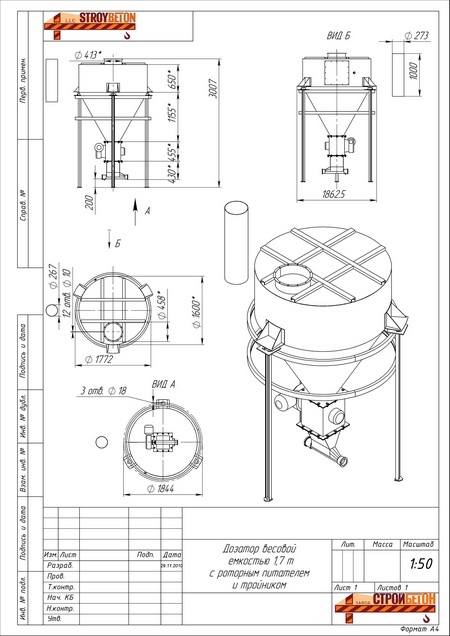

1. Project for KNAUF

The dispenser was required 1.5 cubic meters. For a chalk with a rotary feeder to transmit components to the air system.

As a result, the client developed and put a dispenser – a weight dispenser 1.5 cubic meters. Included with 3 tensodes and a weight display panel and transmission of Tenzo-M signal, filter, pneumatic mushroom.

Since the client has his own control system, the control panel was not supplied. The cost amounted to 192,400 rubles.

For production, a drawing was developed.

2. Project for Chelindlizing (production of dry mixtures)

The client needed to dose 2 components – cement and sand. After that, it was necessary to transfer their mixer. Important recipes, automation were important.

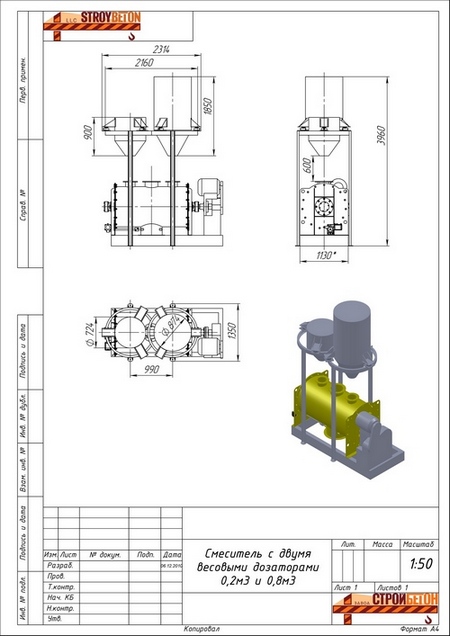

As a result, the client was developed and delivered – the dosage system consisting of a 0.2 kub.m dispenser, a 0.8 cubic meter, control panel.

The system includes:

- Two dispensers in the kit (container, tensodists, lower pneumatic mushrooms, vibrator, dust filter, raising for lifting over the mixer)

- control panel (Siemens Simatic control system, power connectors for connecting supplies, mixer, vibrators, valves, extensions)

The program of the complex was also developed. As a result, the client received a system that produced the right amount of dry mix after start.

All data can flexibly tune (the weight, the time of operation of the vibrators, the mixer, etc.).

The cost amounted to 584,000 rubles.

For production, a drawing was developed.