Synergetic is a large and well-known detergent manufacturer.

They needed a new line to expand their production. On request, we developed the project, worked out the automation and air purification. We then manufactured the equipment and accompanied the project during the installation phase.

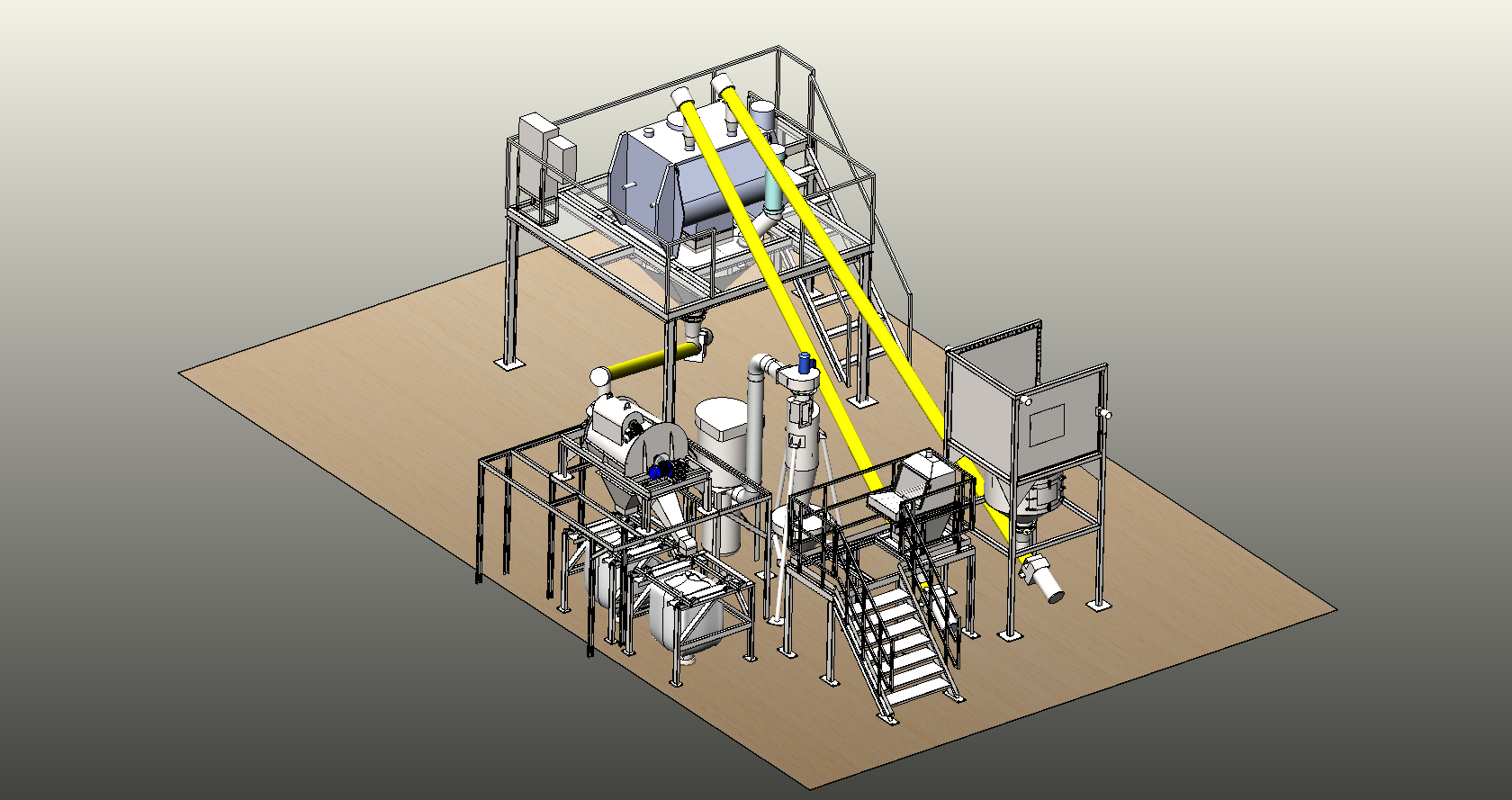

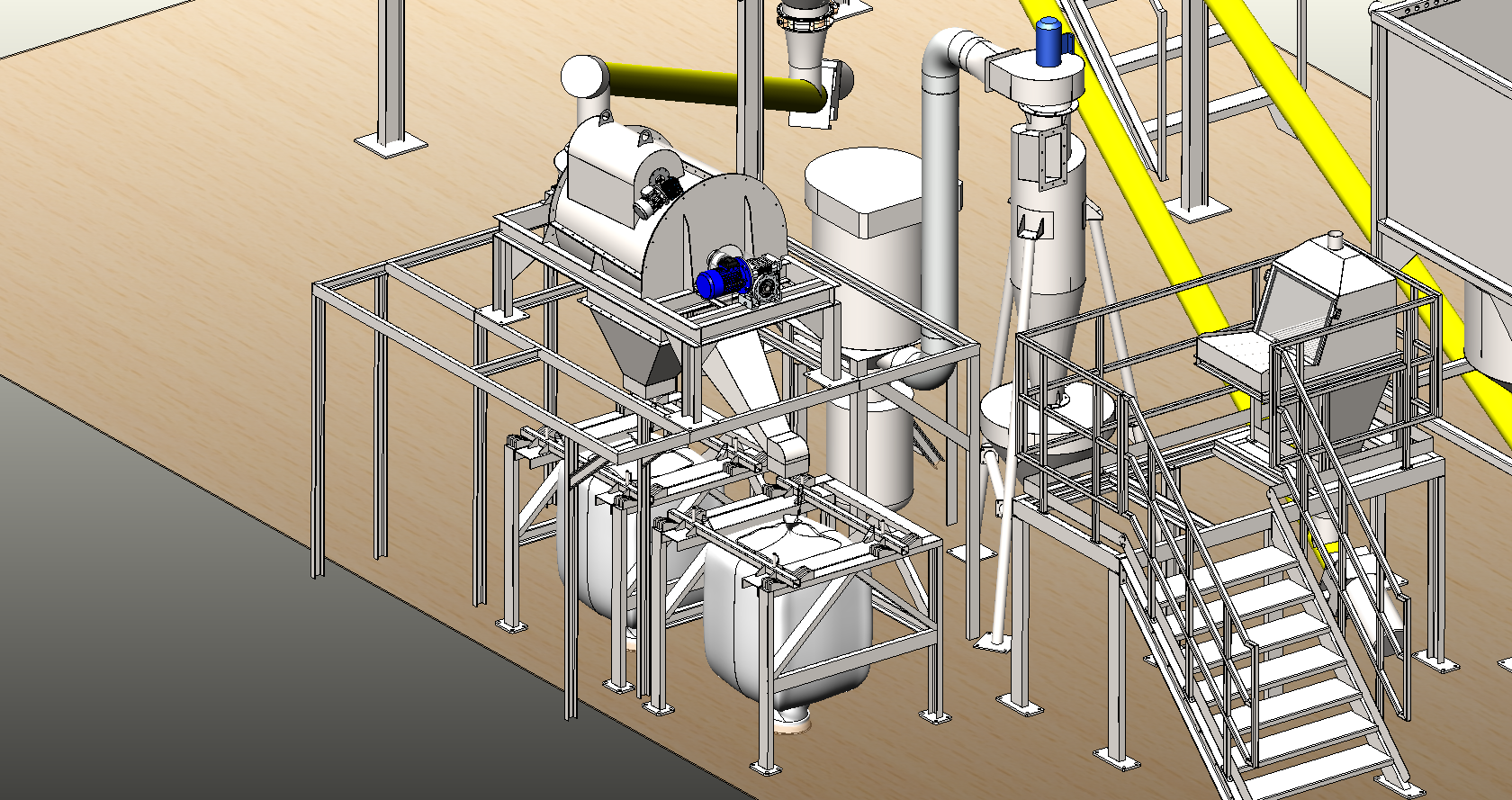

Line composition

The input components come from a big-bag rasterizer and a paper bag rasterizer.

The product base and additive are further fed into the mixer, where mixing takes place and the finished product – washing powder – is obtained.

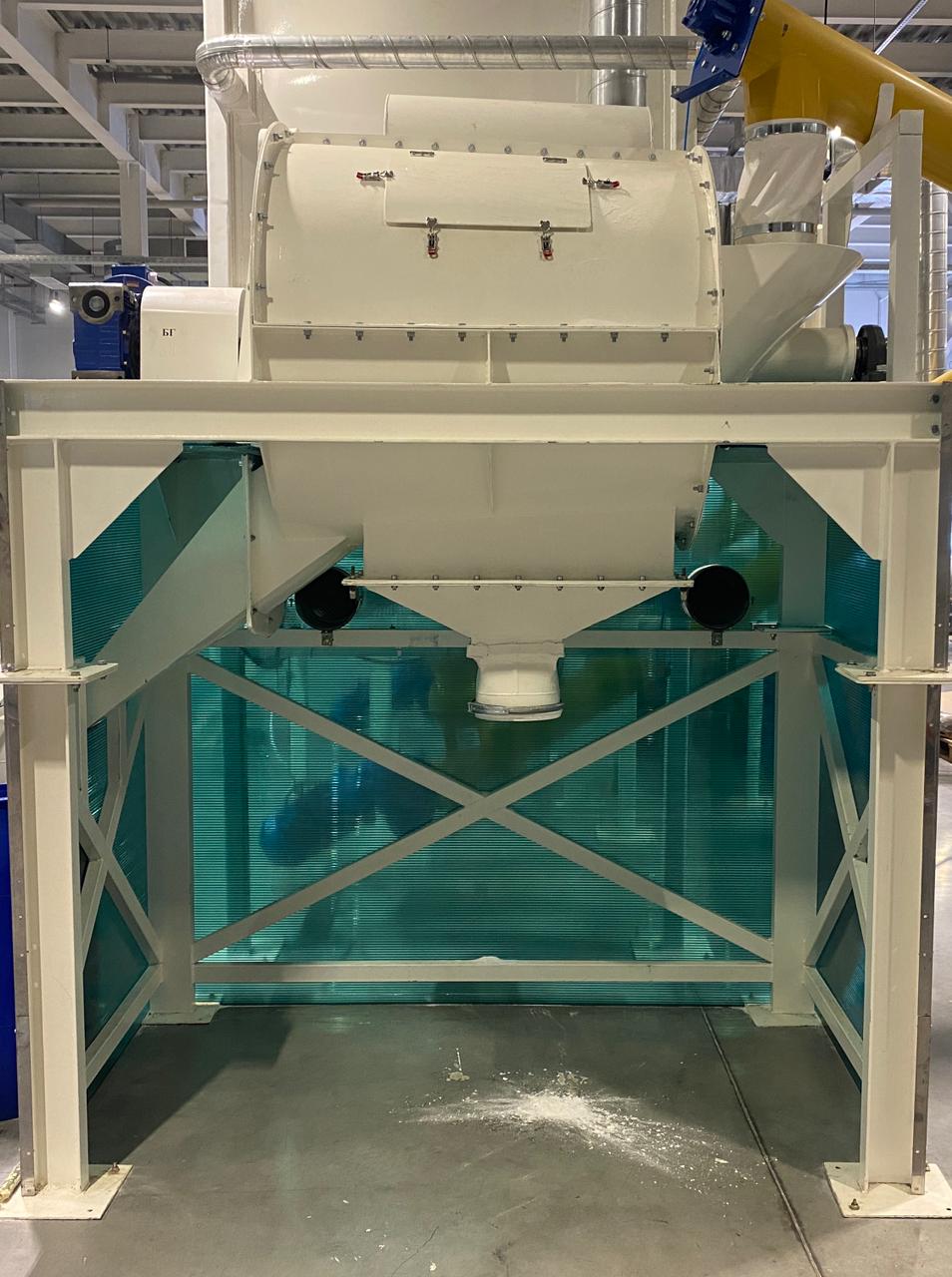

The powder is then sent by augers to a trommel screen with screen beating (powder is prone to clogging and without this option clogs the screen), where lumps and other inclusions are removed. The trommel screen is fully enclosed to prevent dusting.

After that the finished product is packed into big-bags, the screenings from the screen are fed into a separate big-bag.

The line is equipped with a powerful exhaust hood with filtration, which allows to completely prevent dusting during the melt of the initial components.

View a full description of the line and equipment.

Production photo