Microdisers of the MBF series are designed for voluminous accurate dosing of various bulk and powder materials. Microdanters are produced by WAM, Italy and are characterized by high accuracy, reliability and ease of work.

The scope of application

Microdrotes are widely used in the production of dry building mixtures, glass industry, chemical industry, at concrete plants and wherever there is a need for a periodic accurate dose of small doses of additives.

For example, in the production of dry mixtures in one kneader of 1 cubic meter. Often it is required to serve from 4 to 6 different additives in an amount of 1 to 5 kilograms.

Sometimes it is done manually, but this leads to errors and a deterioration in the quality of the mixture.

Therefore, microdosterers are usually used.

The presence of a tile allows you to effectively dose powders with fibers and increased stickiness.

- Look at the example of the microding line at the dry mixture plant (project in St. Petersburg).

- News with shipment.

Description of the work

Above the microdector is a receiving hopper with an addition. The microdant is configured for a certain supply speed, for example, a typical microdector from our price list supplies 105 cubic meters. per hour.

On the plant control panel, the right feed time is tuned and after that, before each batch, the dispenser automatically turns on and supplies the right amount of additive to the mixer.

View a similar microdant of Russian productionAAMIX Flow M42 microdector.

Send a request for a dispenser online

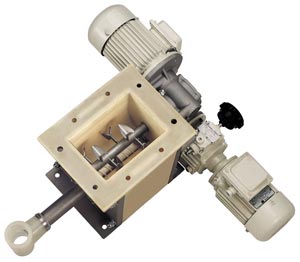

Description of the design and competitive advantages

For different materials, different screw structures are used, the frequency of the screw and the power of the drives. Therefore, when ordering a dispenser, it is important to indicate the dosage material.

- The stainless steel or technical polymer Corps excludes the sticking of the product.

- A borrower and a dosing screw with independent drives, which makes it possible to choose the power and speed of rotation of each

- Performance from 3 to 4000 liters per hour

- The internal geometry of the case ensures the passage of difficult products

- The minimum gap between the screw and the pipe guarantees high dosing accuracy

- A wide spectrum of screws and seals makes it possible to choose a special microdector for a particular product

- Simple service

- Simple cleaning

Complete

- Corps with a reception funnel

- Tor -nourish

- DOSION SHREE

- Two independent drives

Options

- Mechanical variator drive

- Execution of food polymer or stainless steel

- Explosion -proof execution of ATETY Zone 22

- Vertical output

- Square or round funnel

- Electric or pneumatic vibrator

- Dosing auger and pipe covered with a technical polymer Sint to provide a zero gap

Price and order

- The price of a typical microdector is indicated inPrice list

- Download questionnaire for order

Photos of application