The installation of a complete plant for the production of dry building mixtures in Kaliningrad has been completed. The productivity of the plant is 25 tons of the bearing mixture per hour.

More

Designed and made sections of the plant

- Big-begs bastard with components, the feed of beigs is made by built-in crane beams, then the components go to the dose

- Silos and feed from them for a dose

- Module for accurate automatic microdation of additives

- Packing dry mix in bags from 10 to 50 kg

- Drying drum of sand 20 tons per hour, on diesel fuel

- Sifting and storage system of dried sand

- A separate module for packing sand in paper bags (in demand on the market)

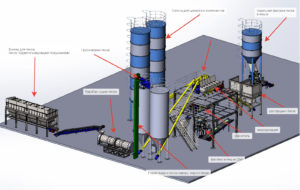

Project

Each project is unique, so our designers make a complete model of the project for each plant. We create a 3D model full of flat drawings with all sizes, a pneumatic scheme, a scheme of streams of materials.

Each element of the plant is precisely mating with another, the client receives all the boarding points for foundations, air wiring, etc.

3D model, with signatures (click to increase)

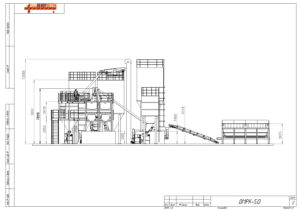

one sheet of a flat project with dimensions (click to increase)

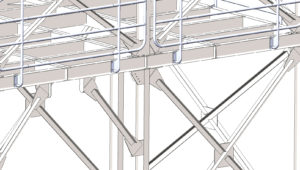

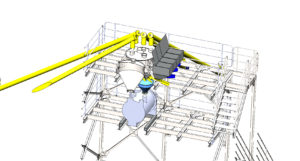

Drawings and model of the main 3-storey tower of the plant (click to increase)

Drawings and model of the main 3-storey tower of the plant (click to increase)

The exact connection of all parts of the plant = quick installation (click to increase)

Production and installation

Production took 3 months and included the production of a frame, mixer, melting, microdes, packaging, drum of sand drying, bunkers, etc. There were also ordered – a burner for the drum, a screw.

Separately, a program has been made to manage all the factory with the withdrawal of all information to the industrial touch panel. From it, all the nodes of the plant are managed. Also, each node has independent control.

Each part of the plant was mounted in production and checked in the work so that during installation there are no extra costs for launch and commissioning.

All photos are increasing below, click to increase.

Packing of dry mixtures in valve bags, 15 tons per hour

On the left – a filter with an hood, for fine air cleaning with dust collecting, in the center – packing, on the right – testing the plant from the central remote control, training

Dusia and microdation

mixer

Silos for cement, etc.

Bunker for the supply of sand for drying to the drum

Drying drum of sand

Cyclones for exhaling air from the drum

Our supercommand and control panel

Order of the plant

To order the plant, enter your data below and we will contact you and advise on equipment, nuances of launch and installation. You can also call or write according to the data from RadelContacts.