The uniqueness of the plant is that ordinary packaging cannot accurately and quickly bandage the powder of bentonite clay.

The largest bentonite clay manufacturer in Russia, in the winter of 2020, turned to the Aamix factory with a request to test our fas-km3 packing for packing clay powder. This package is an analogue of the German packs Haver & Boeker, completely pneumatic, made in Russian automation and Italian pneumatics.

The largest bentonite clay manufacturer in Russia, in the winter of 2020, turned to the Aamix factory with a request to test our fas-km3 packing for packing clay powder. This package is an analogue of the German packs Haver & Boeker, completely pneumatic, made in Russian automation and Italian pneumatics.

More

How did the process of tests and design occur

Having received the product, we conducted tests of packing with bentonite clay at our factory. To do this, we installed a bunker over it, organized the supply of clay and fashed in test parties in working mode. And we and the customer were satisfied with the accuracy and speed of packing.

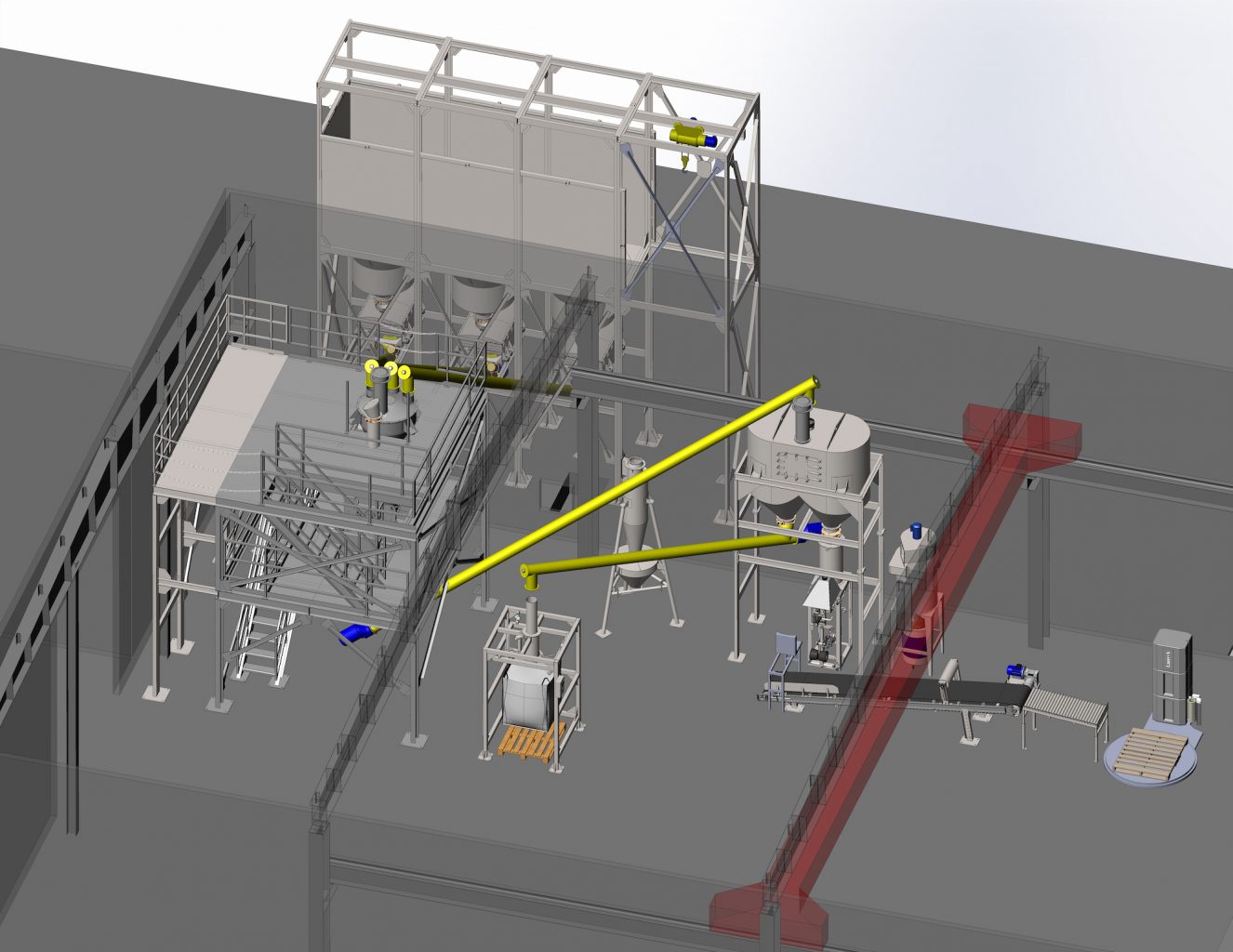

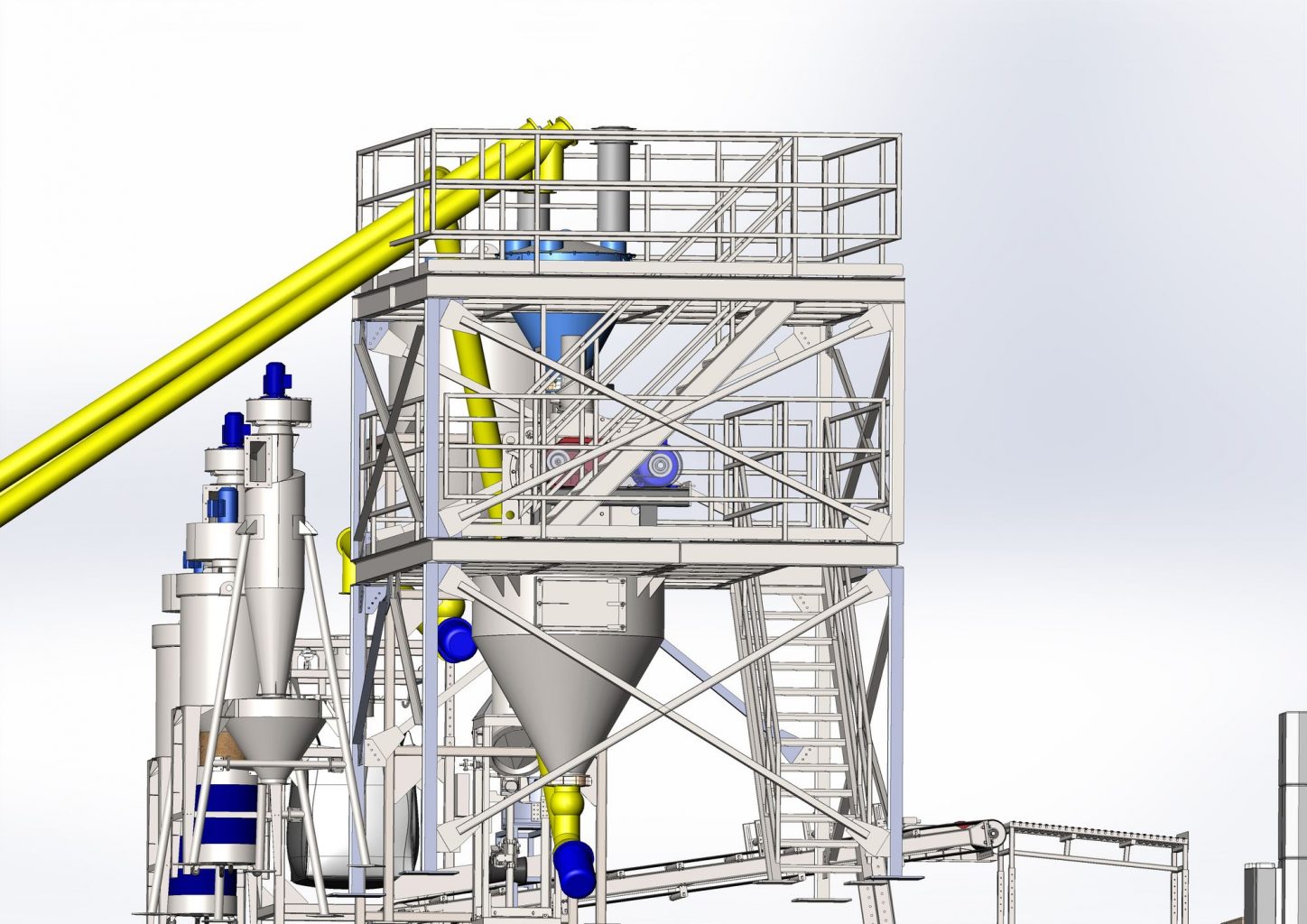

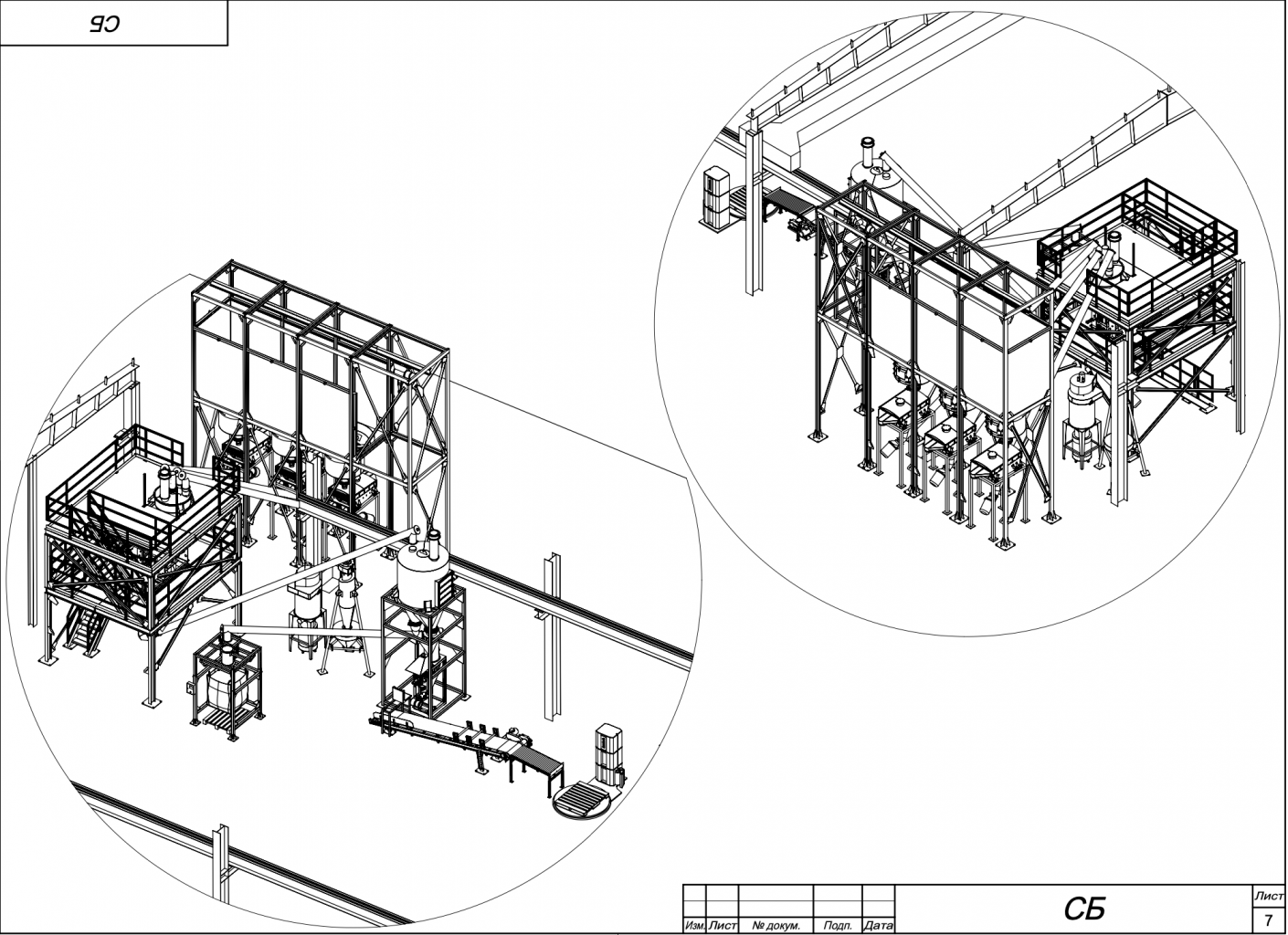

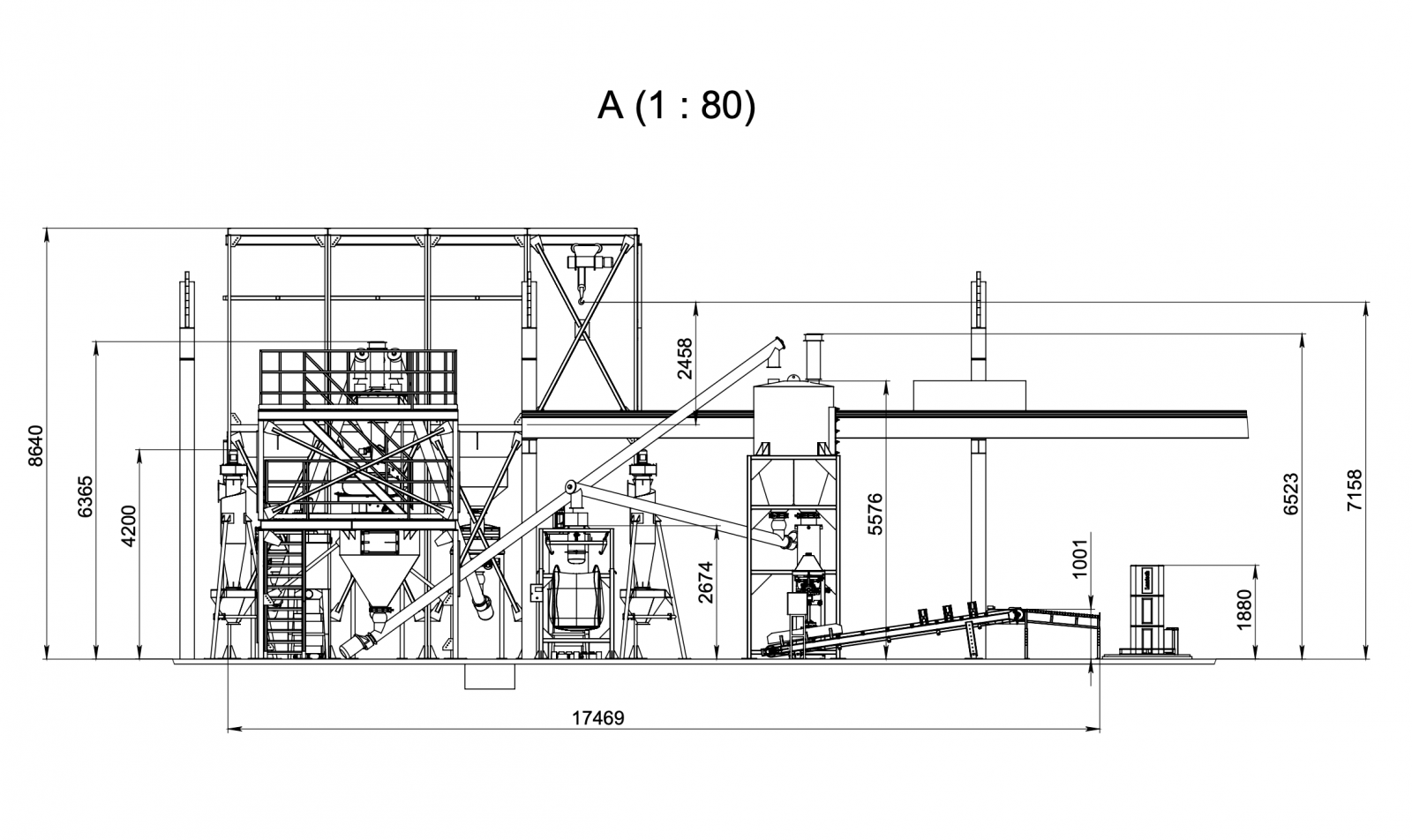

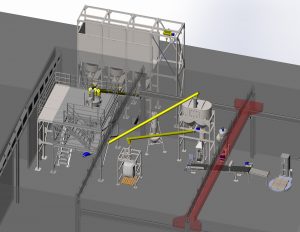

After that, we signed a preliminary contract and made a full project of the plant. As usual, with an accuracy of millimeters, we enter the plant into the building (existing or future), calculate all loads, air, electricity, prepare all imported components for the order (see below).

Further, the customer with the project and calculating the cost of the plant contacted the Uralsing leasing company in Yekaterinburg. After passing all the checks, we entered into a contract and began production.

Description of the plant

- The factory faces products in valve bags and in Big run.

- Bentonite clay arrives in the Big Bigs from the quarry.

- Next, there is a bending, sifting, feeding into the mixer.

- In the mixer, clay is mixed with additives and transmitted to the packing.

- In the workshop there was a limited height and the layout was made for a specific workshop.

- Unique !!!Completely diluting the plant with air purification has been done. First, there is a cyclone for a strong hood, then from it the air goes to the thin cleaning filter. On all dispensers are filters.

- All transmitting equipment in boxes, a separate zone of diluting packaging, a zone of diluting bags.

Installation

In April 2021, all produced and imported equipment reached the customer and we began installation.

The plant was mounted, an electrician, air.

Bugs!An interesting nuance – during the tests over the packing there was a small bunker and the package program was tuned in a performance of 15 tons per hour. However, when the package was installed in real production, the larger pressure of the column of the material from the large bunker greatly accelerated the package, to about 50 tons per hour, which led to a decrease in accuracy. Since we ourselves program plants and our engineers and programmers have both qualifications and experience, we rewrote the program in a week and now everything works according to the customer.

Result

At the time of writing, the news works with full load.

We, the whole team of the Aamix plant, are very happy to make another plant that benefits – produces the right materials that improve business and people’s lives.

Photo of the project

Photo from installation

You can always contact us to order such a plant. Go toContacts.

See also

- Packing of dry mixtures Fas-km3-Pneumo

- Factories of dry mixtures

- The live ether of our engineers with the story what are the plants of dry mixtures and how they differ.Look at YouTube.