The mixers for the production of dry building mixtures produced by the Aamix plant are highly of quality, durability, ease of work and complete mixing of components.

The mixers for the production of dry building mixtures produced by the Aamix plant are highly of quality, durability, ease of work and complete mixing of components.

The mixer is fully produced in Russia using the most modern technologies.

According to a computer 3D models, production drawings are made. Then on your own industrial machinelaser cuttingPerfectly accurate details are cut. Then the assembly occurs at our metalworking enterprise and the installation of reliable gearboxes (Pskov), automation (Aries), valves, electricians and pneumatics and, if necessary,deglomeratorsAnd another strapping.

Due to such a modern approach, we can produce not only typical mixers, but also unique for the requirements of certain projects.

Our faucets have been working for years both at small enterprises and in large plants of dry mixtures not only in Russia, but also abroad.

Some of our clients

Some of our clients

- Danogyps (KNAUF), mixer 2200 liters.News with a photo.

- Shipment of two mixers in polyplast.News with a photo.

- Video of the test test of the mixer before shipment.Look.

- Gazprom. SCS production plant with vermiculite.Watch the news with the photo.

- LLC “Lime Construction mixtures”.News with a photo.

- Petroenerit. A large plant in St. Petersburg for the production of CCC.News 1, News 2.

- Hess AAC (Holland). Automatic plant for the production of CCC, delivery to Europe.News with a photo.

- And more than 200 clients in Russia and the world

Cycle for the production of the mixer

- design – creating models, constant improvement

- Metal processing – first laser cutting according to drawings, then bending and assembly

- The motor gearboxes of the Pskov plant, one of the most reliable in the world, work stably even in India and Asia

- Aries Automation, large Russian company, real competitor Siemens

Standard delivery set

The price of typical models includes:

- The system of backwatting units with a witchcintering (bearings are carried out and do not wear out, the air support significantly increases the duration of the stuffing)

- Three loading neck

- Lower pneumatic mushroom

- Pneumatic sampling sampling system

- Two pre -installed flanges for installing activators (deglomerators)

An article about the types of mixers of dry mixtures.

View prices for faucets in the price list.

Send a request for a mixer online

The principle of operation of the mixer

The mixers of dry mixtures Aamix Prof function according to the principle of liquid layers formed mechanically.

A special shape, location and speed of rotation of mixing devices create a centrifugal vortex -shaped movement, which allows you to project materials in a three -dimensional angle and mix them with each other.

This is a guarantee that components with various granulometric indicators and density are mixed accurately, efficiently and in a very short time.

- Watch the news with photos and videos about the installation of the mixer of 2200 liters at the Danogips factory (KNAUF).

- Watch the news with the conclusion of the laboratory about the quality of mixing.

- An article about the types of mixers of dry mixtures.

Competitive advantages

- Strong mixing chamber made of carbon, wear -resistant or stainless steel

- Brief mixing time (1-4 min)

- The maximum uniformity of the mixture

- Excellent reproduction of portions

- Minimum wear small requirements for technical support

- Simplicity in the regulation and replacement of mixing devices

- Ease of cleaning and access to all the internal details of the machine

Technical characteristics

|

Characteristic |

Es-ts. |

Prof |

Prof |

Prof |

Prof |

Prof |

|

The volume of the mixer is full |

liters |

350 |

600 |

1300 |

1600 |

2200 |

|

Length |

mm |

1800 |

2190 |

2700 |

2835 |

3100 |

|

Weight |

kg |

840 |

1060 |

1620 |

1690 |

2900 |

|

The supply voltage |

IN |

380 |

||||

|

Engine power |

KW |

12 |

18 |

36 |

36 |

55 |

|

Air pressure in the pneumocylinder |

MPa |

Up to 0.65 |

||||

|

The speed of rotation of the shaft |

About \ min |

60 |

||||

|

Mixing mixing time |

min |

From 2 to 6 |

||||

View prices for faucets in the price list.

Additional options

- Bunker for acceptance of the mixture mixture

- Steel for difficult working conditions, stainless steel, special structural materials

- The possibility of wear -resistant coating

- Bearings of the bags with a lining ring and aeration or with a lubricant

- Liquid supply system

- Decompression shield

- Sampling system

- A wide range of mixing devices (boxed, gear, with blades, with gear blades), also in the option with a wear -resistant coating

- Microding of additives

Video from a working factory

This video was filmed in the fall of 2015 at the factory installed in St. Petersburg.

The plant worked from May to October with a performance of 30 tons of a mixture per hour. The plant was created by our company from a unique project and ending with the chief installation and production of the first parties.

The mixer is working without stopping to the present.

Photos

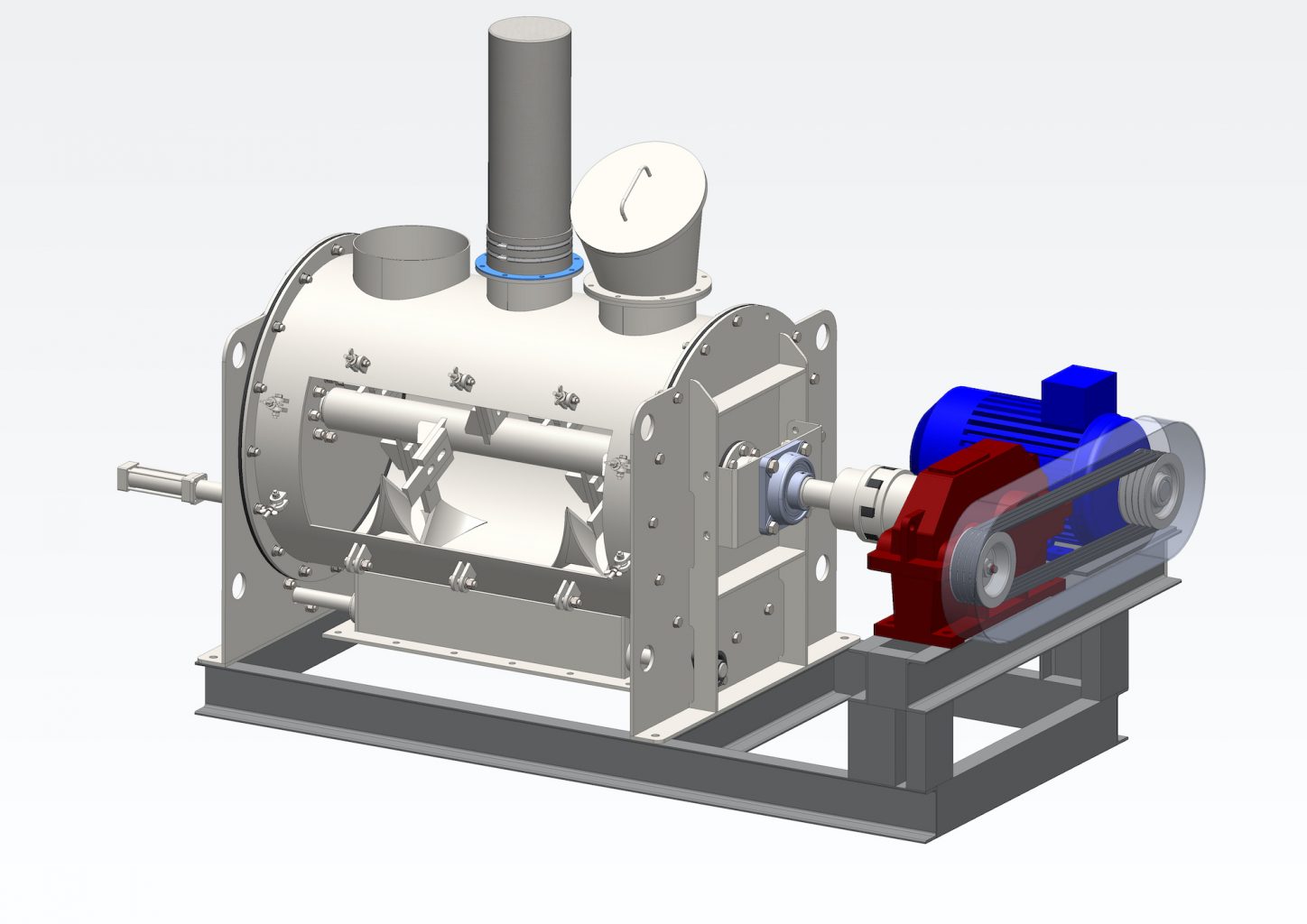

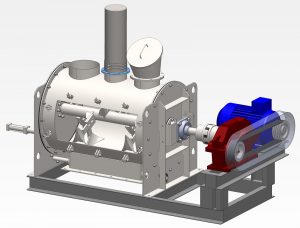

Photo of the mixer with installation

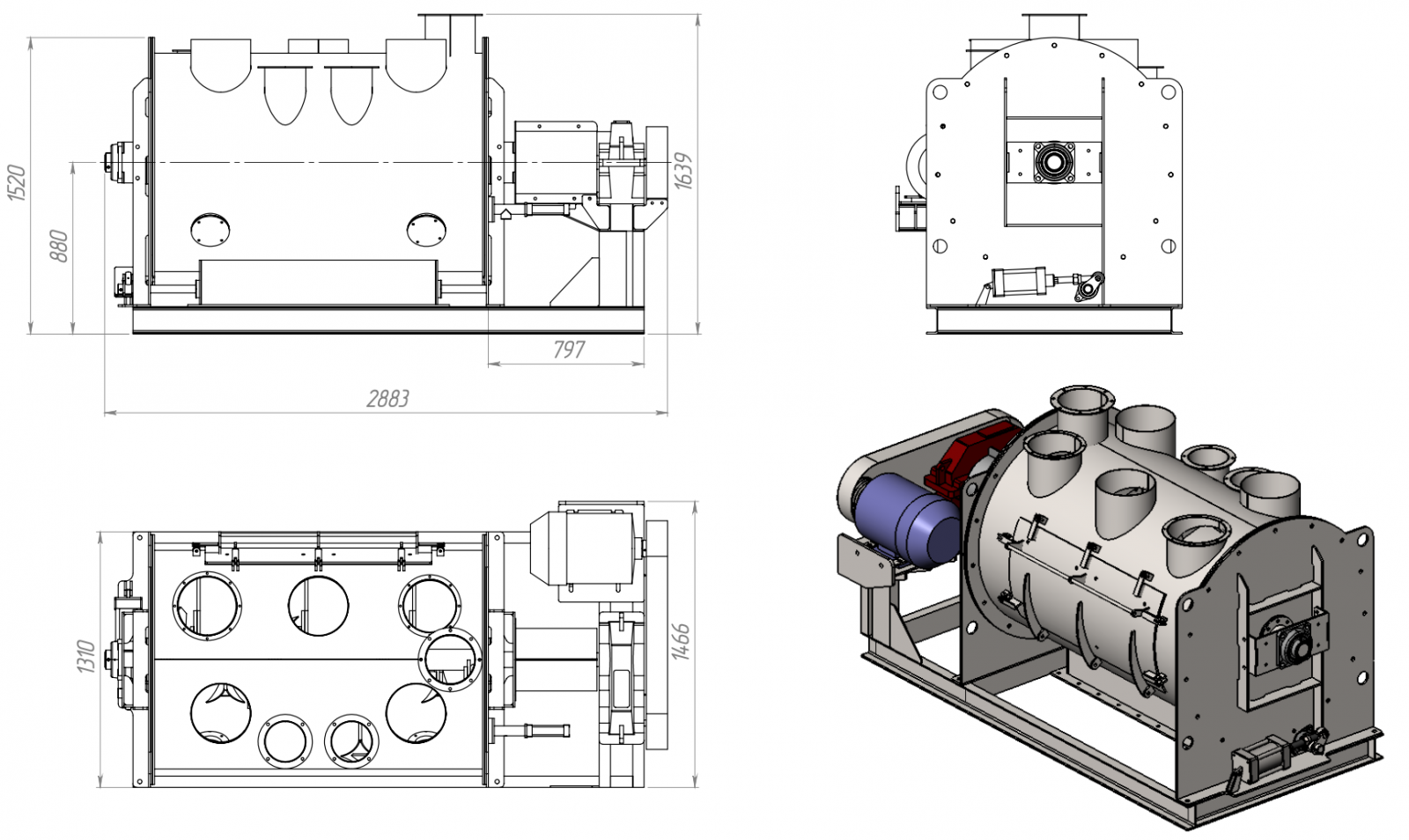

Drawing of the mixer 1.6 cubic meters.

Model model

Send a request for a mixer online

Watch also

- An article about the types of mixers of dry mixtures.

- Types of drives of mixers of dry mixtures

- Go to the page with a list of mixers mixers.

- Description of the complete plants of dry mixtures.

- Description of bulk dispensers(stand in front of the mixer).

- Description of packing machines(for packing in bags of mixtures made).

- Description of the deglomerators(for better mixing of additives).