In most dry mix plants, one of the most problematic areas is the bagging area of the bagging plant.

In most dry mix plants, one of the most problematic areas is the bagging area of the bagging plant.

At this site, the work is monotonous, takes place in harsh conditions (dust, noise) and yet the productivity of the entire plant depends on this location.

And if there are three or four filling machines running at the same time, it leads to high labor costs and difficulty in maintaining continuous production.

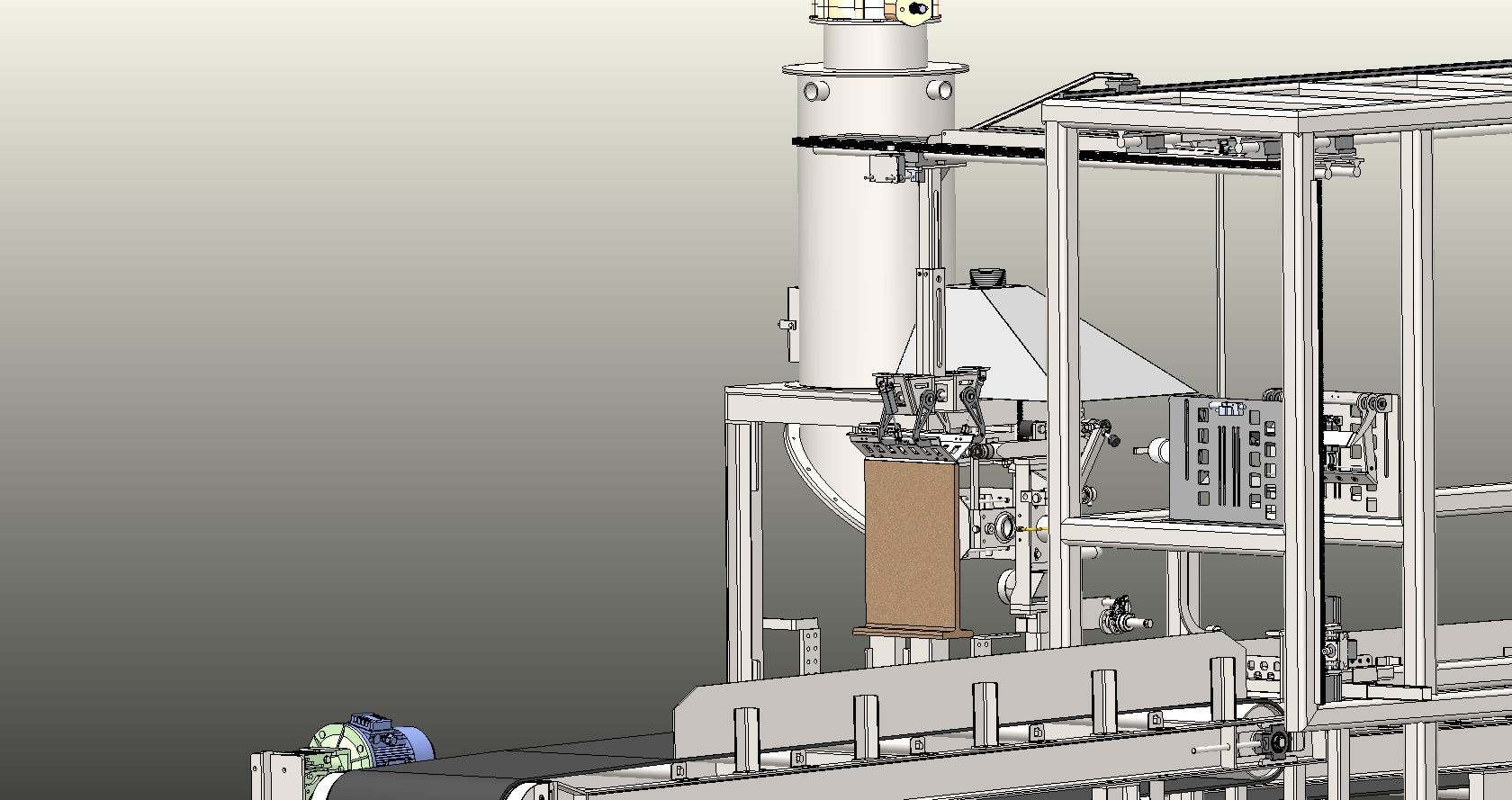

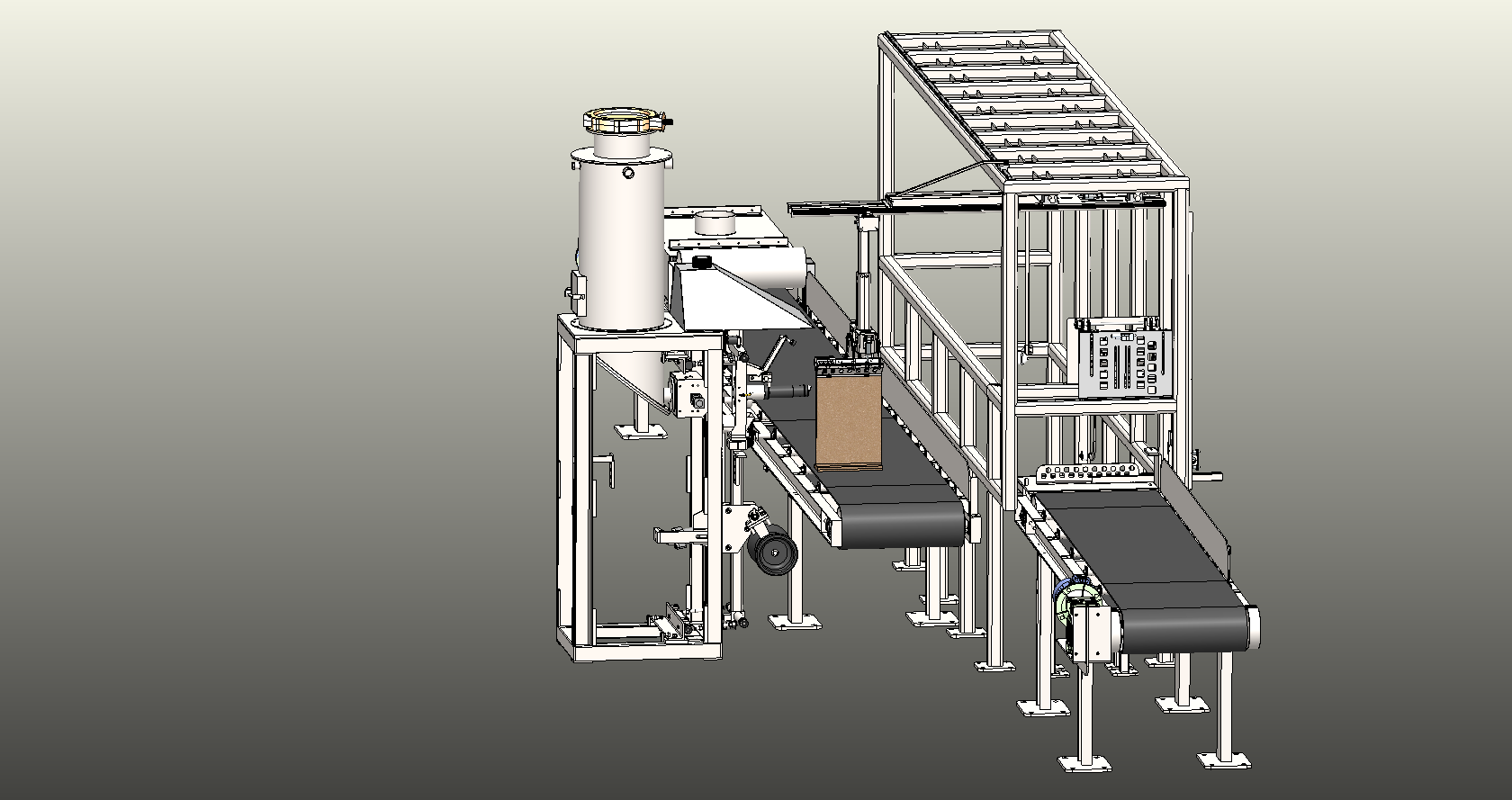

The AAMix NM-1 bagging robot solves this problem and significantly reduces operating costs. At the same time, the stability of the production process is improved, which leads to increased profits.

The unit is made on the basis of the best European models and adapted to our fills and plants.

Work order

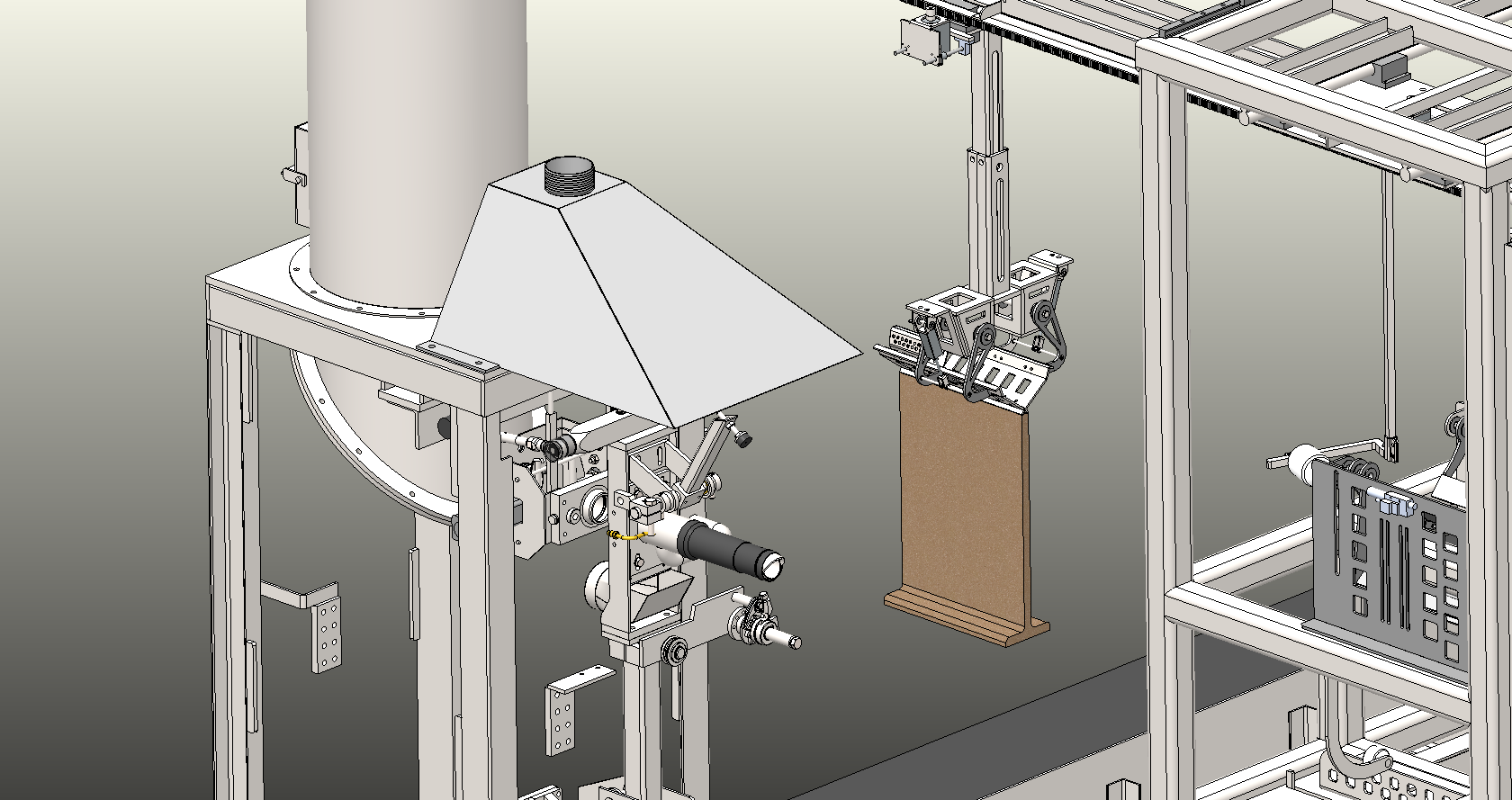

The empty bag is pulled out of the stack with the vacuum gripper and moved to an intermediate position where the bag valve is opened and secured by the manipulator.

The manipulator carries the bag to the filling machine module and places it on the filling nozzle, while the valve is held securely in place.

One bag is moved and inserted at the same time as the next bag is removed from the stack and the valve of the next bag is opened.

During operation, the attachment interacts with the filling machine by exchanging signals and controlling the bag magazine.

The filling modules report when they are ready to accept a bag. If no module is ready, the filler pauses the operation.

The magazine feeds the next stack of bags into the working position immediately after the vacuum gripper extracts the last bag.

Installation composition

- Frame for three filling stations.

- Bag extractor with vacuum gripper.

- A preformer valve opening device.

- Biaxial clamp manipulator.

- A robot attachment with bag spreading.

- Bag feeding robot.

- Conveyor storage and tare feeding conveyor.

- Remote control.

- Vacuum pump.

- Control cabinets.

Modernization of the filling unit and economic effect

We made a big report at the Baltimix-2024 conference in which we told how to modernize an old node, the economic effect of modernization. Read the report. Given that we have long since implemented automatic bagging of mix on pallets, the level of plant automation has reached 90%.

When designing or modernizing your plant, we will offer options for full and partial automation and select the most suitable option.

Order and price

For ordering and cost calculation write to info@isilos.ru or call tel.: +7 (812) 408-41-82.

In plant operations, one of the bottleneck areas that requires a lot of manual labor and often results in a drop in productivity is the stacking of finished dry mix bags onto pallets.

Using a robot to stack bags on pallets solves this problem.

Composition of the robotic cell

- Robot palletizer KAWASAKI CP180

- Grip for bags up to 50 kg

- Pick Up Conveyor

- A pedestal for the robot

- Metal security grille

- Optical security system

Description of the production process

The system is a closed security perimeter within which products are automatically stacked.

Bags enter the Pick Up conveyor via existing conveyors. The stacking area is enclosed by a safety grid and light barriers. The robot stacks the products one by one, first on one side away from itself, then on the other. Empty pallets are stacked on a pre-marked place.

After filling one pallet, the robot automatically starts stacking the products on the other side. The safety system automatically opens the optical barriers to the filled pallet.

Once a full pallet has been removed from the security perimeter, the forklift driver visually checks the security area and, after verifying that it is empty, performs a line reset, which causes the optical barriers to automatically lock to the entrance.

Equipment

Equipment

- KAWASAKI SP180 articulating robot (1000 bags/hour)

Robot body

Control cabinet

Robot control and training console - Pick Up Conveyor

- Bag gripper 50kg

- Optical barriers

- Security perimeter

- Robot pedestal

- Pneumatic bag leveler

- Buffer conveyor 850 mm

- Bag baler 1600 mm

- Installation and commissioning

Order and price

For ordering and cost calculation write to info@isilos.ru or call tel.: +7 (812) 408-41-82.

See also.

- Report on the bagging robot at the Biltimix 2024 conference

- A robot for stacking bags on pallets.

- MES control system for dry mix plant.

- Drying drums from 5 to 50 tons per hour, on gas, coal, electricity.