When installingmixerDry mixtures on the frame with a standard solution for making a finished mixture from it is the installation of a bunker under it.

When installingmixerDry mixtures on the frame with a standard solution for making a finished mixture from it is the installation of a bunker under it.

When the mixer pneumatic forwarding is opened, the finished mixture quickly falls into the bunker, the valve closes and the mixer begins a new cycle.

In parallel, at this time a ready -made mixture from the hopper or paces into bags or is transmitted further along the technological line.

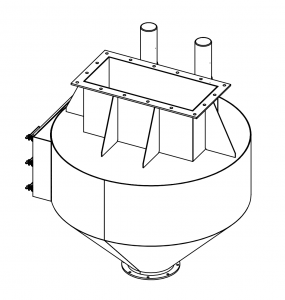

At the Aamix plant, we have developed and successfully use a classic bunker in many factories, in which:

- The level sensors for the alarm about overflow or devastation are built -in – this avoids emergency situations

- 2 sleeve filters were installed to filter excess air, which is formed when the mixture is failed

- Luke has been made for revision and maintenance

- sealing compounds with the mixer is provided

A typical bunker model has a volume of 2 cubic meters, the cost of this model is in conjunction with 197000 rubles sensors and filters.

Any other volumes and layouts are possible.

- Download the drawing of the bunker.

- See an example on the photo report from the factory.

- Description of the mixer of dry mixtures.

Photo of the bunker from the factory in Kalinigrad.