As part of the construction of a complete factory for the production of complex dry building mixtures in St. Petersburg, a line was developed and made for automatic dosing and supplying additives to the mixer in an amount of 1 to 30 kilograms per in collaboration.More

As you know, when microdosizing the additives with the mixer, there are usually several problems that make it difficult to automate:

As you know, when microdosizing the additives with the mixer, there are usually several problems that make it difficult to automate:

- often additives have increased stickiness or fiber in the composition

- additives are delivered in bags from 10 to 50 kg, which makes it difficult to unpack them and feed

- Dosage of small volumes is difficult, because Sques cannot transmit such a volume, and the microdosterers do not put above the mixer, because There is not enough space

Our engineers have developed a system that allows you to supply additives from microdation without loss in the mixer, it is convenient to unpack and store the additives themselves, while the additives are supplied with special microdectors, which solves problems of reduced makeability.

Go to the description of equipment for microding additives.

Also, this system is fully automated and manual labor is required only for unpacking, feed, dasing, recipes – everything is controlled by controllers.

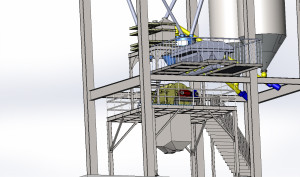

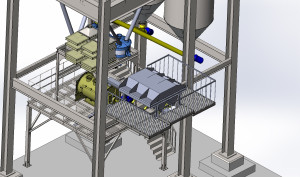

The task is to submit 6 additives to the mixer, without loss, weighing from 1 to 30 kg., Additives in paper bags from 10 to 50 kg.

- On the platform, 6 drives of paper bags with hoods, in explosion -proof design are installed on the platform

- Under the dispensers, the accumulative container to which are connectedMicrodrower MBF, WAM in the design and performance of the performance necessary for this additive

- From microdosaters, additives fall into a closedThe strip conveyorwith special. the tape excluding sliding down, which fits them into the mixer

- The entire system is controlled by the Siemens controller, all the recipes and work cycles for each collapse are automatically made in automatic mode

- The level sensors in the container containers allow you to control the filling process and stop the work in the absence of additives

The Aamix plant develops and produces reliable and unique automation at its own plant for the production of building materials. Among our customers are firms as KNAUF, LSR Group and others.

3D project model

See also

- Microding of additives

- Shneki microdation of prof-shmd– Description of the screws with a diameter of 60mm, to dase additives

- Microder MBF– dispenser working in dosing time

- Ribbon conveyors