The Aamix plant develops, produces and supplies throughout Russia and abroad weight dispensers for bulk materials, such as cement, sand, grain and others.

The produced weight dispensers are of high quality and ease of integration into various automated accounting systems.

The produced weight dispensers are of high quality and ease of integration into various automated accounting systems.

It is also possible to produce and supply not only weight dispensers, but a system of automation and control of a dosage complex.

- Photo report from the client’s factory after a year of work.

- The news about the shipment of the full dosage line into polyplast.

- The news of the order of the re -truttes with a dose from KNAUF (delivered in 2017).

- The news of the shipment of dispensers with the photo.

- News with dispensers in the plant.

The principle of action

The weight dispenser of cement, sand or grain is a container that hangs on the frame. In places of fastening, tensodists are installed to the frame, which transmit information about the current weight of the container to the central remote control.

As a result, the control program always has data on the current weight of the dispenser.

Standardly, at the top of the dispenser, three flanks are made to join the screw transporters, to supply the material to the dispenser and the dispenser filter, to eliminate dust from the air flow out of the dispenser.

When the desired weight of the dispenser is achieved, the automation gives the signal, the lower pneumatic forwarding and all the cement, sand, grain or other loose material come out automatically.

If the material sticks to the walls of the dispenser, then a small vibrator is placed, which is turned on when the valve is opened or if the volume of the dispenser is more than 1 cubic meter, then the aeration system is installed.

How to buy a dispenser

You can choose a typical dispenser (in the table below) or order a dispenser or a complete system for your project. We will make drawings, affirm them with your engineers and produce what we designed. Equipment warranty up to 24 months.

Tel.: +7 (812) 408-41-82, e-mail:info@isilos.ru

Competitive advantages of weight dispensers from the Aamix plant

- Tensodists of the highest category of accuracy, manufacturer Tenzo-M (Russia).

- Pneumatics of Camozzi, Italy.

- Reliable lower valve, pr-in Aamix, Russia.

- Accuracy and accuracy of execution, all parts are made on the laser cutting machine.

Technical characteristics of cement dispensers

Below are the characteristics of three typical dispensers for cement, sand, grain. However, the Aamix plant produces dispensers of any volume, any configuration and from different materials, including stainless steel. To order a non -standard dispenser, we ask you to fill out the questionnaire and send it to us. Within one day, an offer with prices and delivery time will be sent. You can also seesystem of weight dosing individual performance.

|

Indicators |

DV-400 |

DV-600 |

DV-800 |

DV-1200 |

|

Dose material |

Cement, sand, gypsum, ash, grain, etc. |

|||

|

Dosage limits, kg |

20-500 |

20-800 |

20-1000 |

20-1500 |

|

Dosing error, no more than % |

0.5 |

0.5 |

0.5 |

0.5 |

|

Air pressure for the pneumatic system, atm |

6 |

6 |

6 |

6 |

|

Mass, kg |

160 |

190 |

220 |

260 |

Complete

The price of standard dispensers includes: (View price in the price list)

The price of standard dispensers includes: (View price in the price list)

- The capacity of the dispenser.

- Three upper pipe for supplying materials to the dispenser.

- A set of tensodists (Tenzo-M, Russia).

- The lower pneumatic forwarding with pneumatic cylinder, a diameter of 300mm (Russia, aamix) can be set a different diameter and manual or electrical drive, then the cost is recalculated.

- Pneumatic distributor (WAM, Italy).

- Carrying filter.

- Two valve position sensors (WAM, Italy).

That is, by purchasing a standard dispenser, you get a completely finished device that can be built into any line (click the photo on the right to see the set of the valve).

Options (indicated when ordering)

- Doster frame.

- Changing the diameter of the valve and the type of drive, options – electric, manual (pneumatic is placed by default).

- Installation of a vibrator or aeration system.

- Production of the control panel for the entire dosing system.

- Development of a full system for feeding materials, pneumatic transmission.

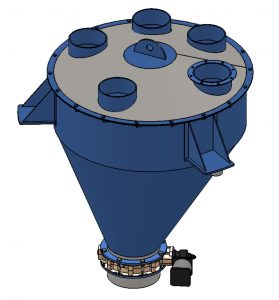

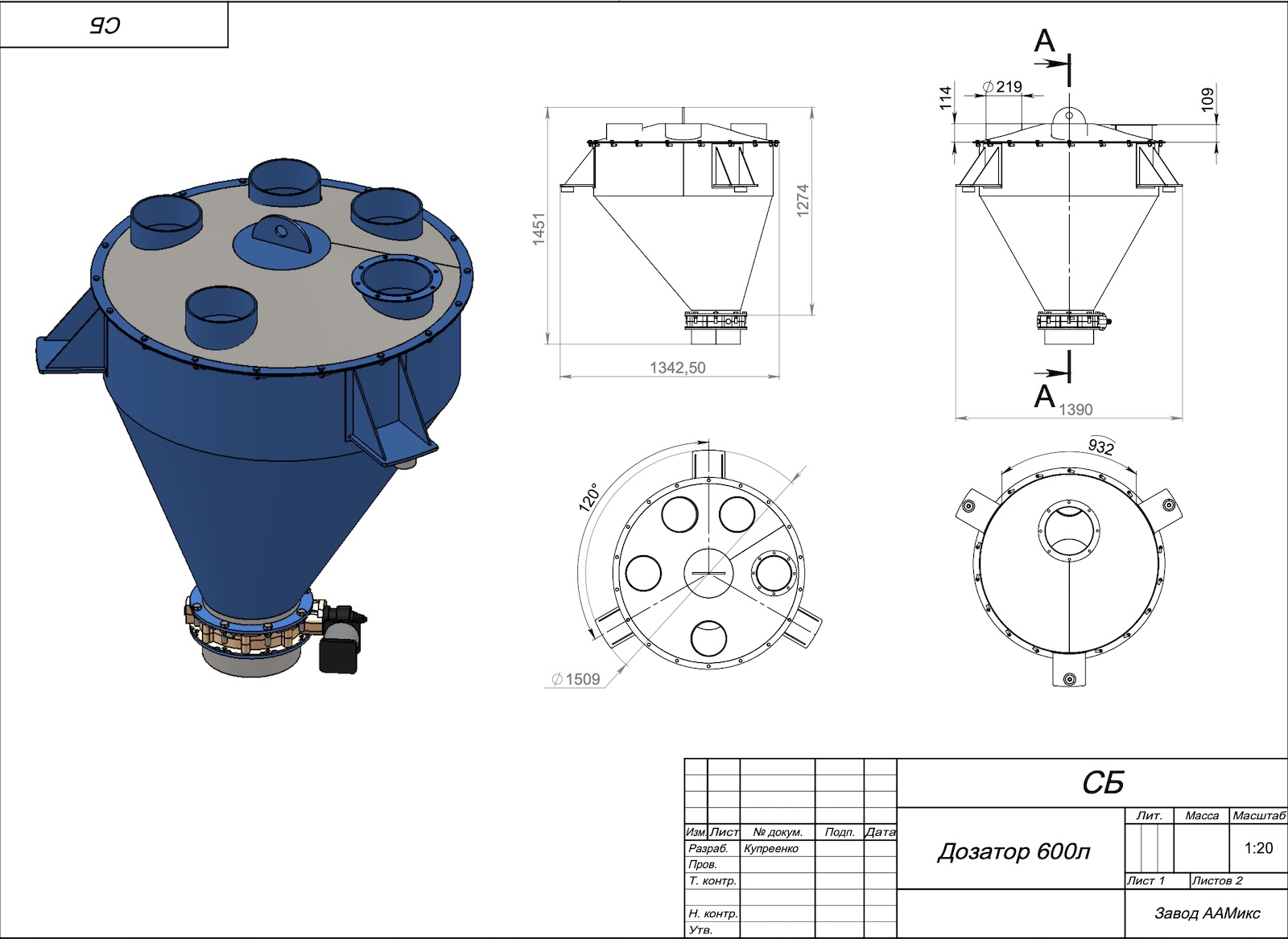

Weight dispenser scheme 600 liters

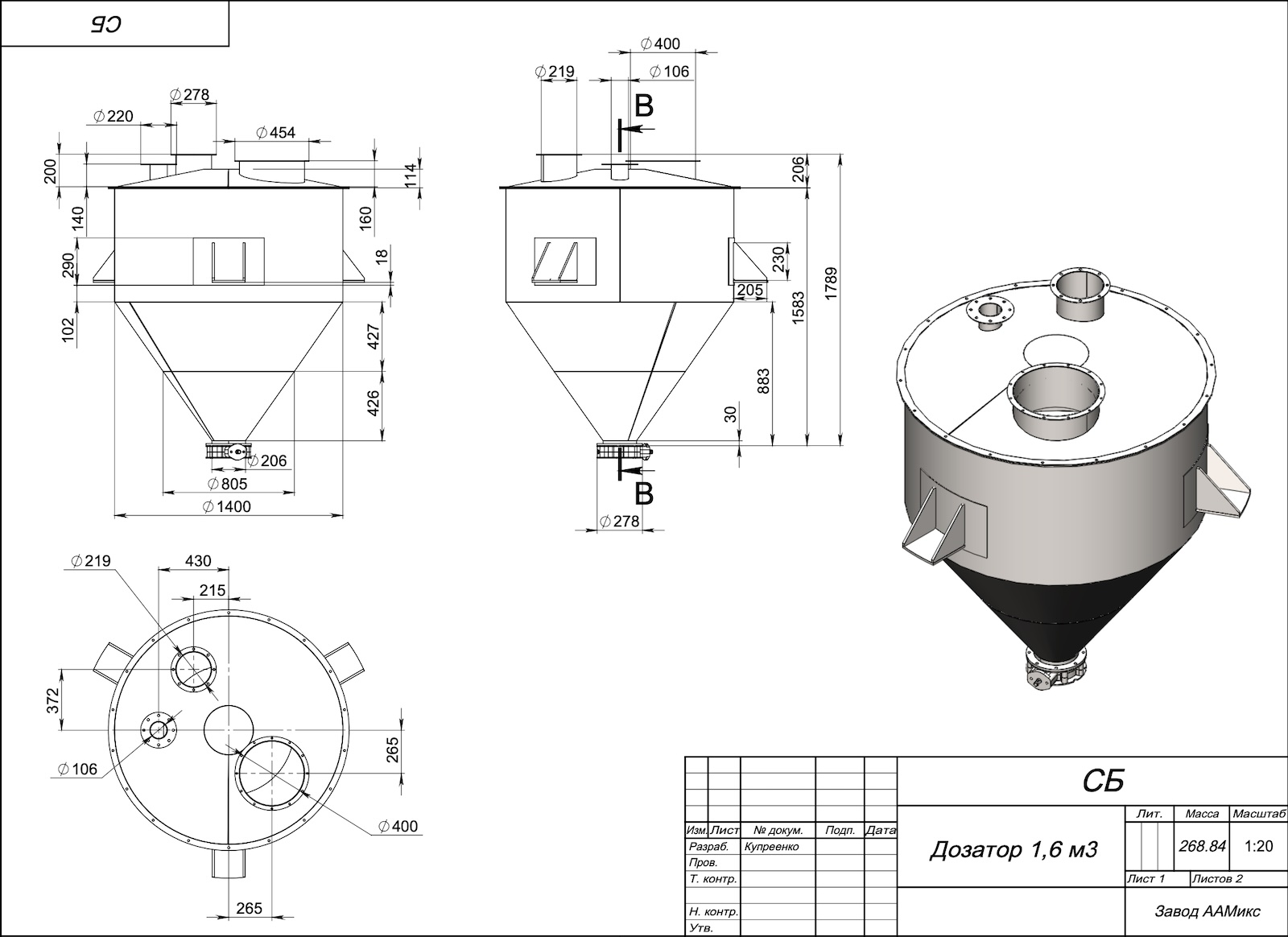

Weight dispenser scheme 1600 liters

Photos from production

Weight dispenser 2 kub.m., KNAUF plant, 2022 production

- Photo report from the client’s factory after a year of work.

- The news about the shipment of the full dosage line into polyplast.

- The news of the order of the re -truttes with a dose from KNAUF (delivered in 2017).

- The news of the shipment of dispensers with the photo.

- News with dispensers in the plant.